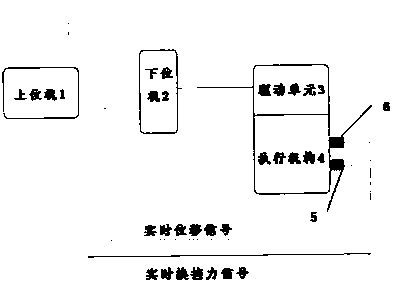

Vehicle gearbox shifting robot control system

A control system and gearbox technology, applied in the field of vehicle testing, can solve problems such as the inability to apply automatic gearboxes, and achieve the effects of credible experimental data, shortened development time, and accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

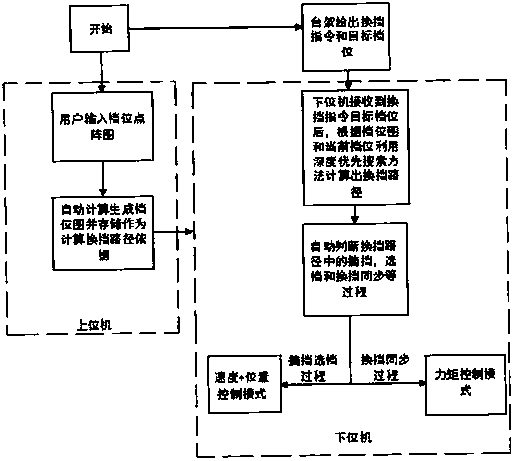

[0092] This embodiment takes a five-speed manual gearbox as an example to illustrate the implementation steps of the entire control method:

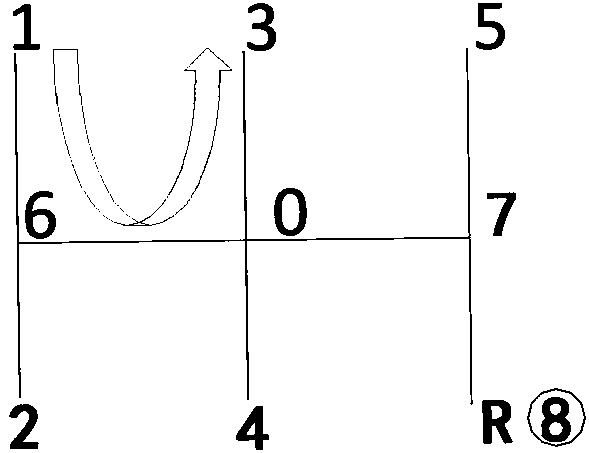

[0093] 1. The user enters the gear relationship according to the actual gear position of the tested gearbox, and the upper computer automatically generates the corresponding gear connection diagram according to the pre-stored gear point matrix diagram, such as Figure 4 Shown is the structure diagram of the shifter of the five-speed gearbox. Figure 5a with Figure 5b It is a schematic diagram of the shifting process, where 1 represents the shifting process, 2 represents the gear selection process, 3a represents the front area of the synchronization area, 3b represents the synchronization area, 3c represents the synchronization area, Sy represents the stroke in the y direction, and Fy represents the shift force in the y direction , Fmax represents the maximum shift force in the synchronization zone, Fmin represents the minimum shift force i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com