Evaluation method for brittleness of shale

An evaluation method and shale technology, applied in the field of oil drilling, can solve the problems of high cost, inability to evaluate shale brittleness, complicated rock sample preparation process, etc., and achieve the effect of low cost and simple sampling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

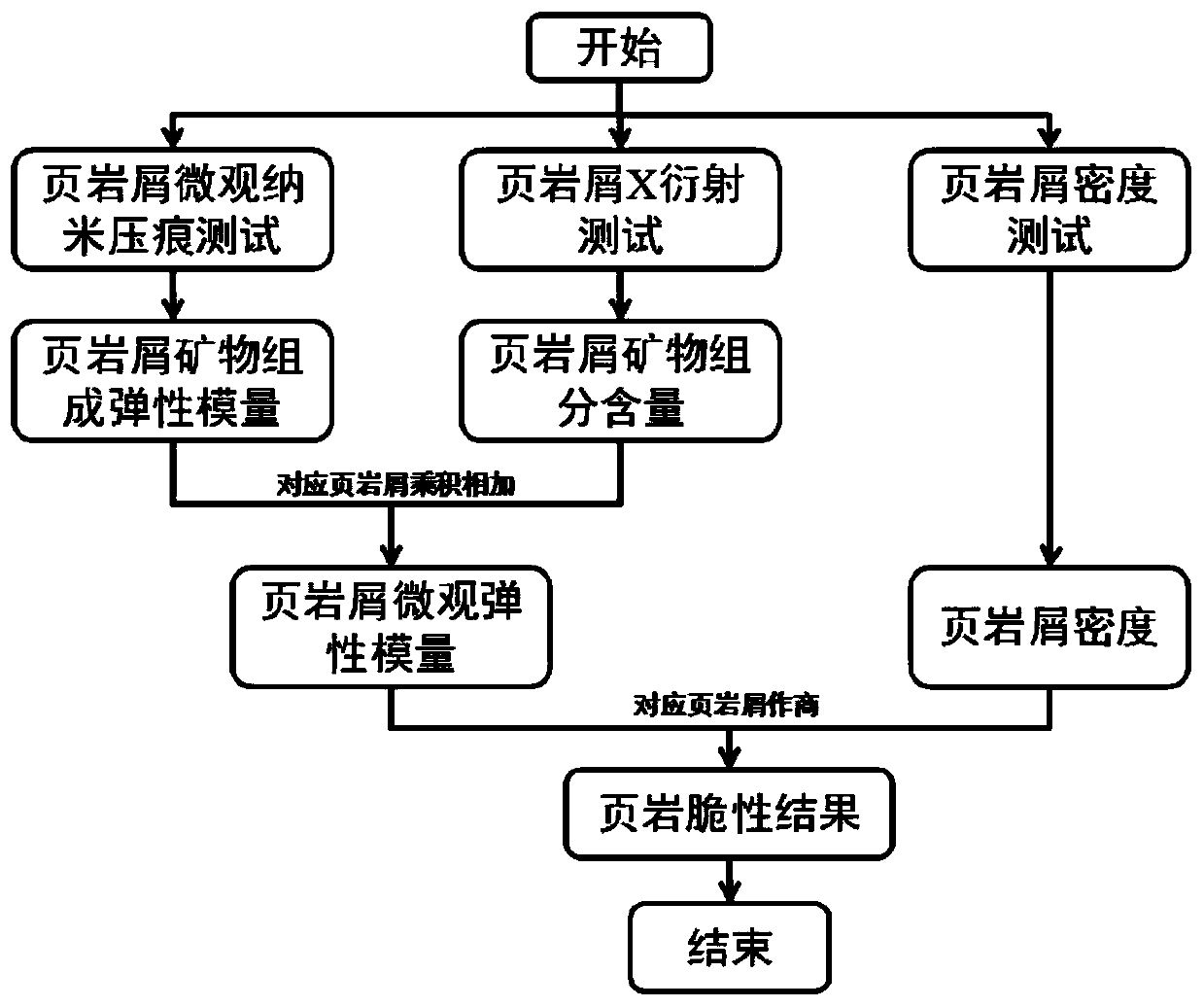

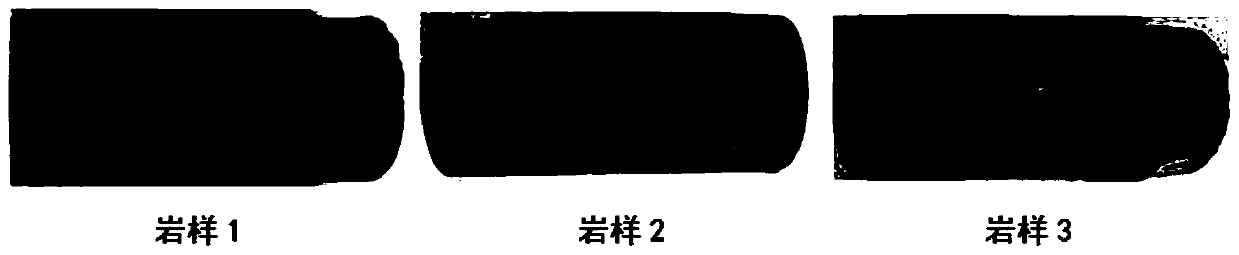

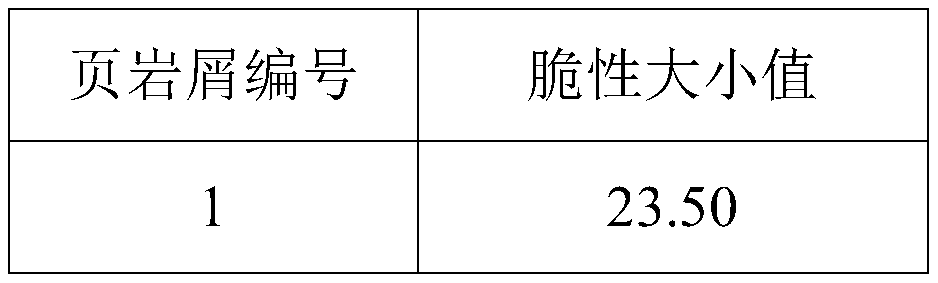

[0020] The shale brittleness evaluation method of this embodiment includes the following steps: (1) Select a group of drilling cuttings from different shale reservoir sections and the corresponding standard shale samples as the test and research objects, and carry out microscopic analysis on the shale cuttings. Nanoindentation, X-ray diffraction, and density tests are used to test the compressive strength of the corresponding standard shale samples (under the same confining pressure); (2) the elastic modulus, The content of mineral components and the density of shale cuttings were substituted into the brittleness evaluation model The relative value of brittleness of the same group of shale cuttings is calculated, as shown in Table 1; (3) The relative value of brittleness calculated from shale cuttings is compared with that of the corresponding standard shale sample (under the same confining pressure) after the compressive strength test degree of fragmentation ( figure 2 )Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com