Control method for acquiring dielectric constant of calibration material in real time

A control method and real-time acquisition technology, applied in the direction of material capacitance, material analysis, dielectric property measurement, etc., can solve problems such as errors, uneven asphalt mixture, and inability to reflect real-time paving thickness and compaction of asphalt in real time. Achieve the effect of simple use, powerful functions, and promote the commercialization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better clearly express the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

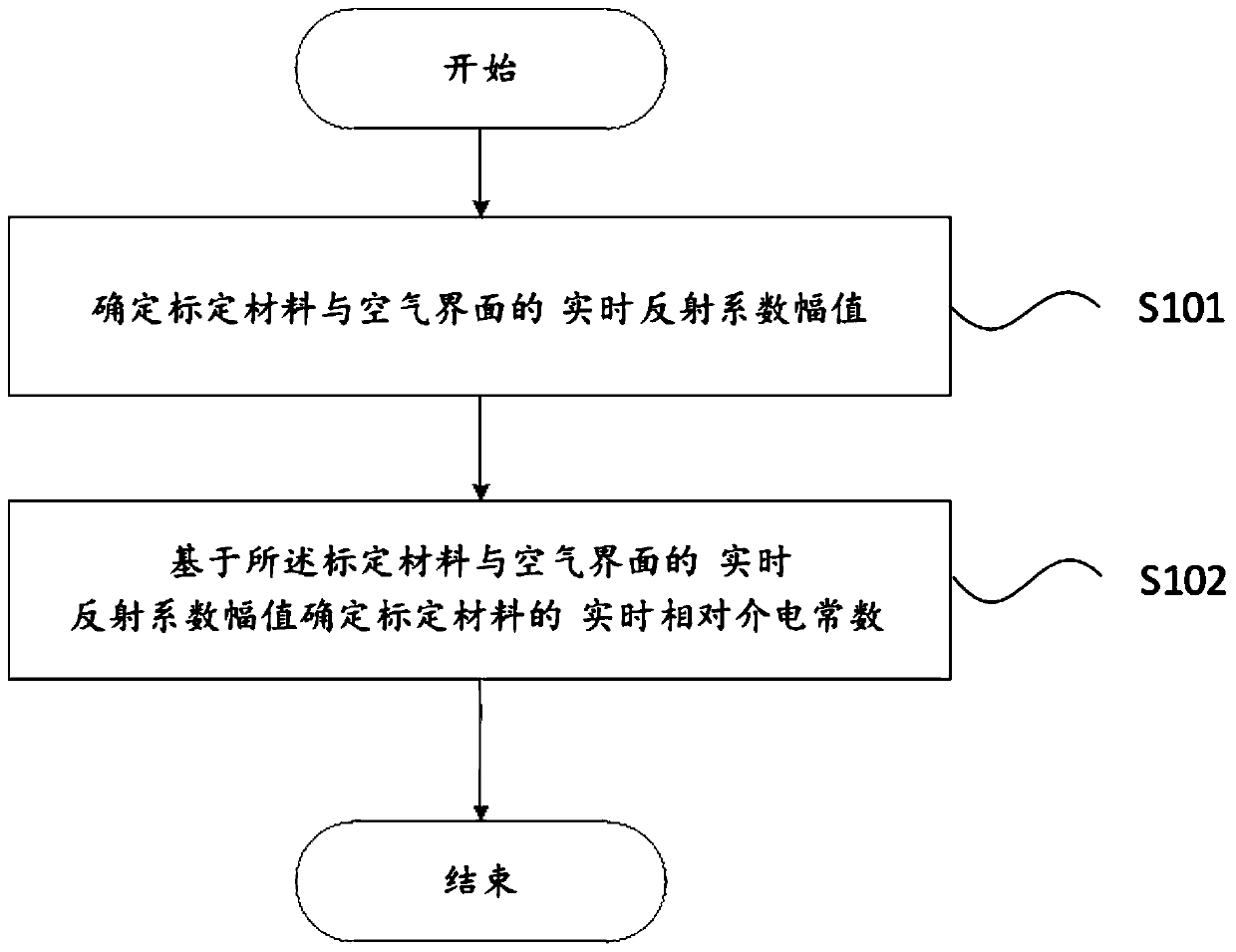

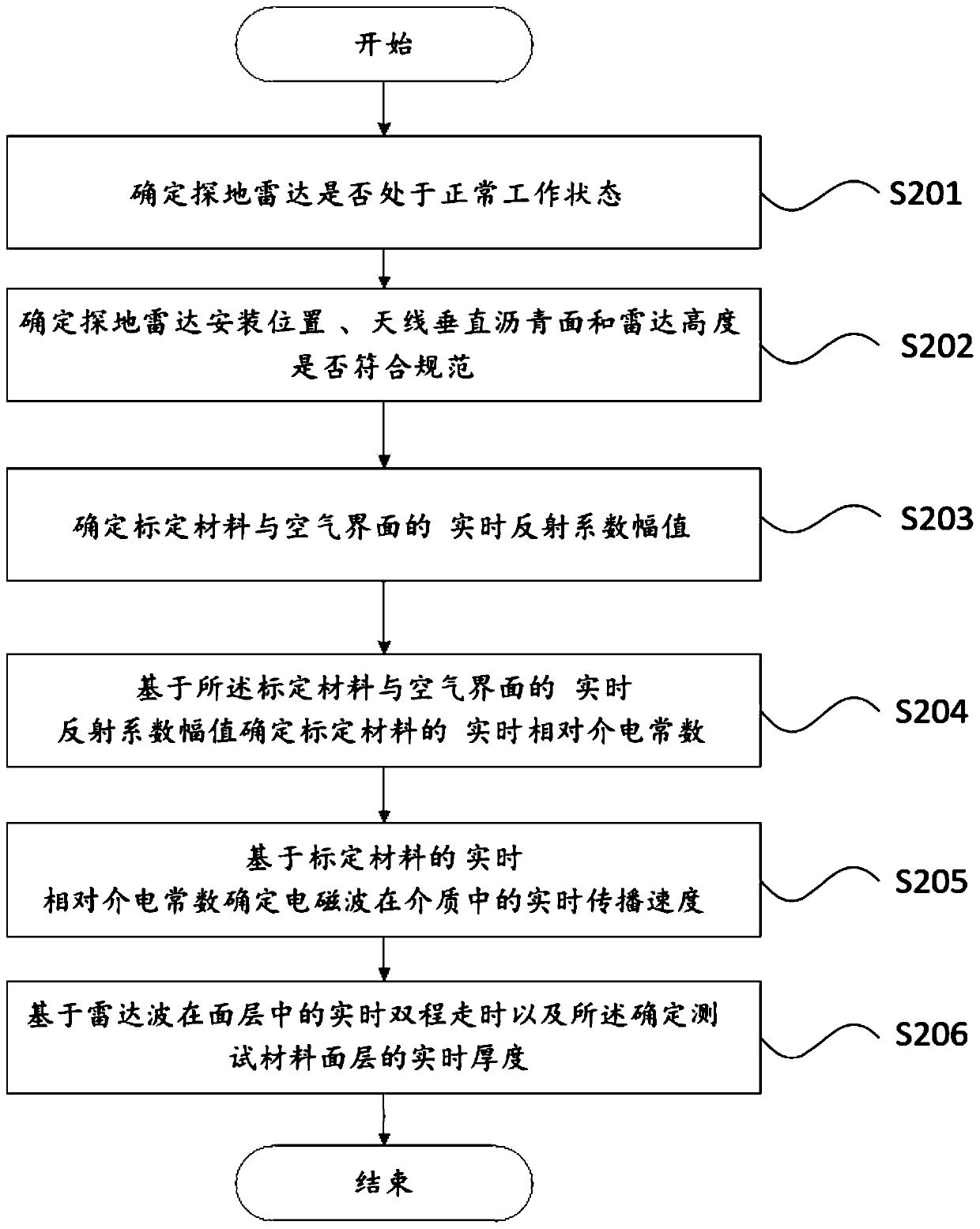

[0050] figure 1Showing a specific embodiment of the present invention, a specific flowchart of a control method for obtaining the dielectric constant of a calibration material in real time. The present invention discloses a control method for obtaining the dielectric constant of a calibration material in real time. The parameter data obtained during the asphalt paving process determines the dielectric constant of the calibration material under real-time conditions, and then reflects the real-time paving thickness and compaction of the asphalt, including the following steps:

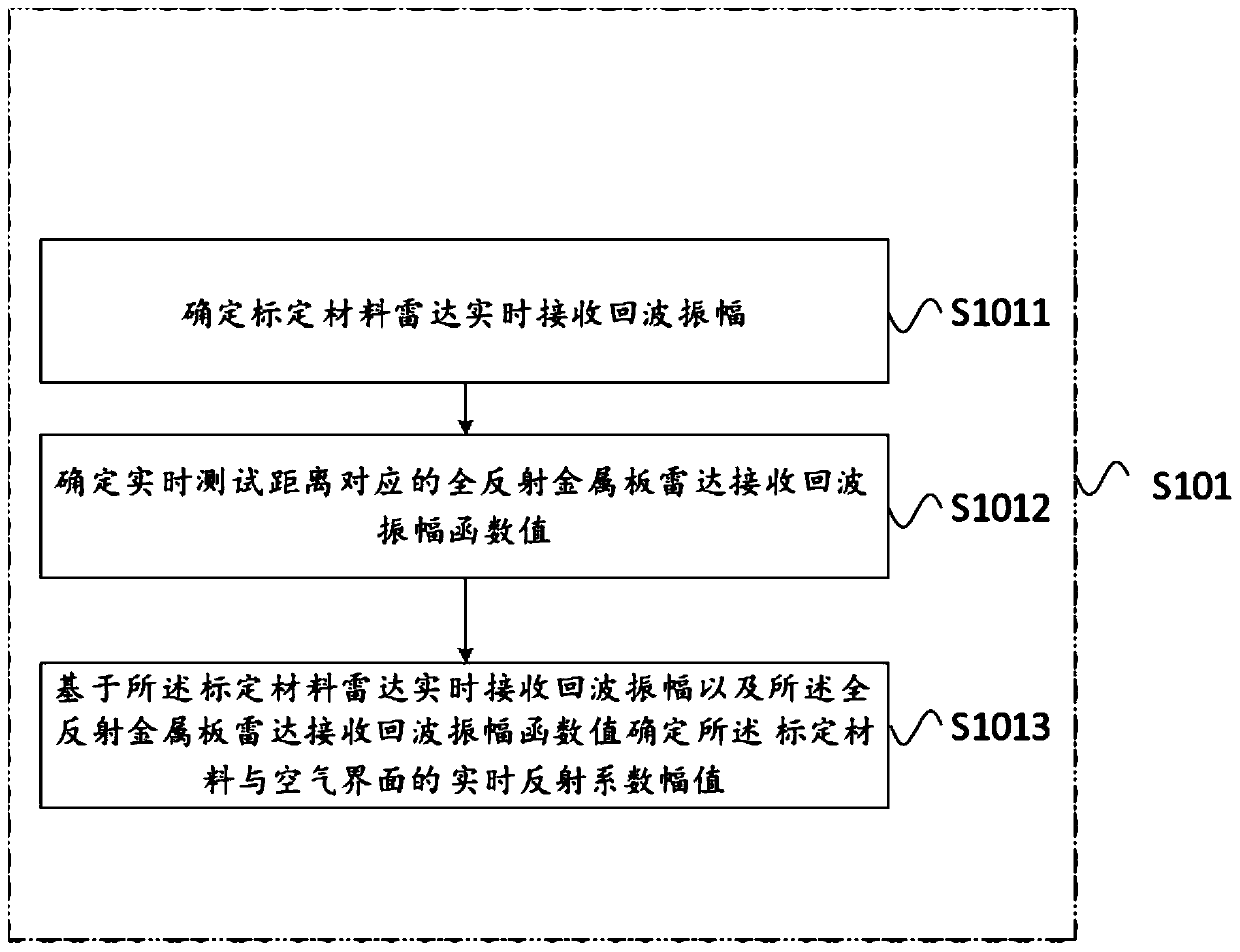

[0051] First, enter step S101 to determine the real-time reflection coefficient amplitude Γ of the calibration material and air interface i , those skilled in the art understand that the calibration material is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com