Transverse grinding outer circumferential surface roughness determining methodMethod for determining surface roughness of outer circumference of transverse mill

A technology of surface roughness and determination method, applied in instrument, calculation, electrical and digital data processing, etc., can solve the problems of difficult direct relationship, low efficiency, high experimental cost, and achieve the effect of improving logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

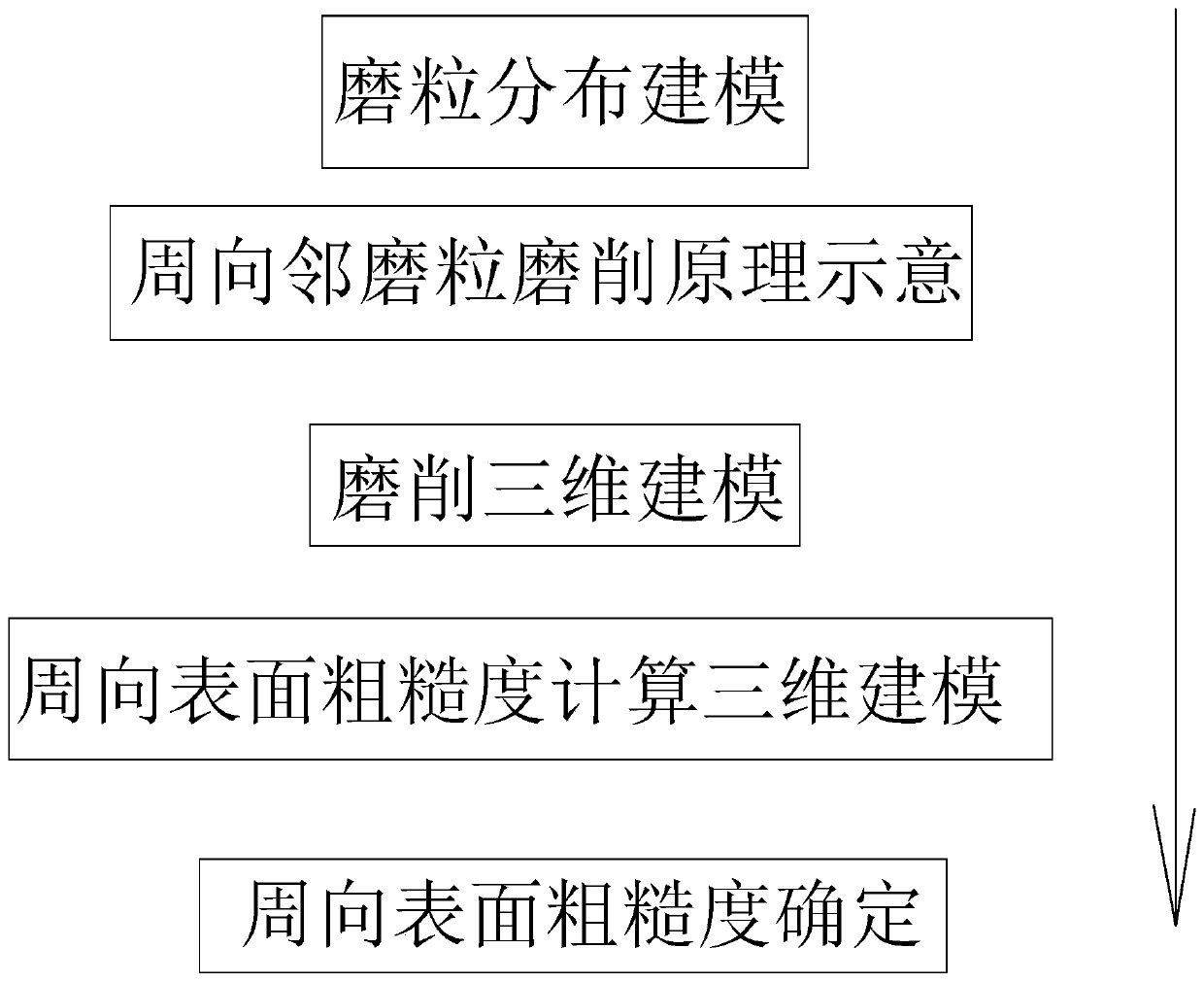

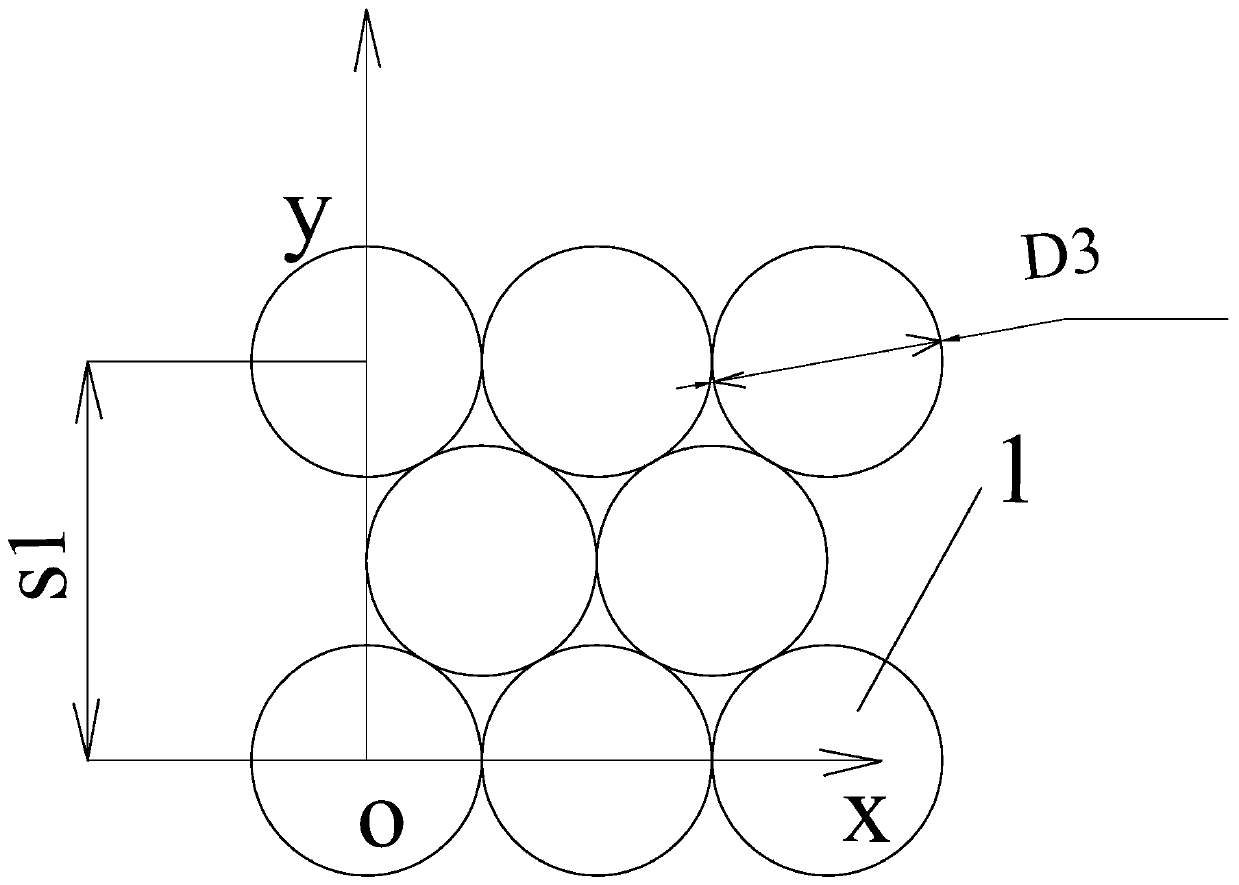

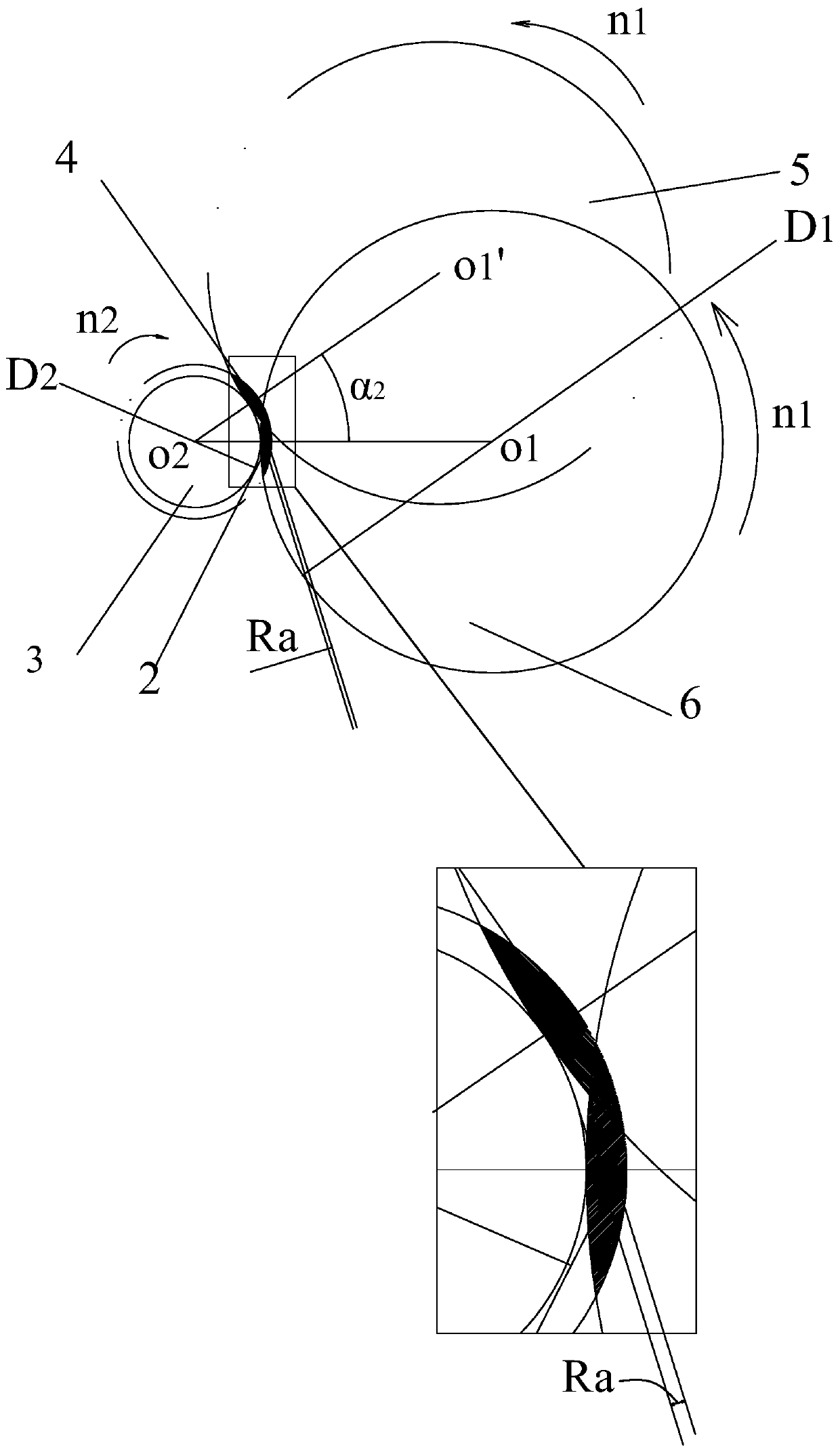

[0030] Embodiment: The method of three-dimensional modeling is used to determine the surface roughness of the outer circumference of the transverse grinding method, and the technical route is as follows figure 1 . figure 1 Among them, the distribution of abrasive grains introduces the distribution of abrasive grains on the circumferential surface of the grinding wheel; the grinding principle of adjacent abrasive grains in the circumferential direction explains the geometric relationship between the circumferential surface roughness and the grinding process parameters of two adjacent abrasive grains in the circumferential direction; the three-dimensional grinding modeling is established 3D model of grinding process; 3D modeling of peripheral surface roughness calculation Establishment of a 3D model for determining peripheral surface roughness. Circumferential Surface Roughness Determination The method for determining circumferential surface roughness is introduced. A method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com