Semiconductor wafer scribing device and method

A semiconductor and wafer technology, which is applied in the field of semiconductor wafer dicing devices, can solve problems such as long process time and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

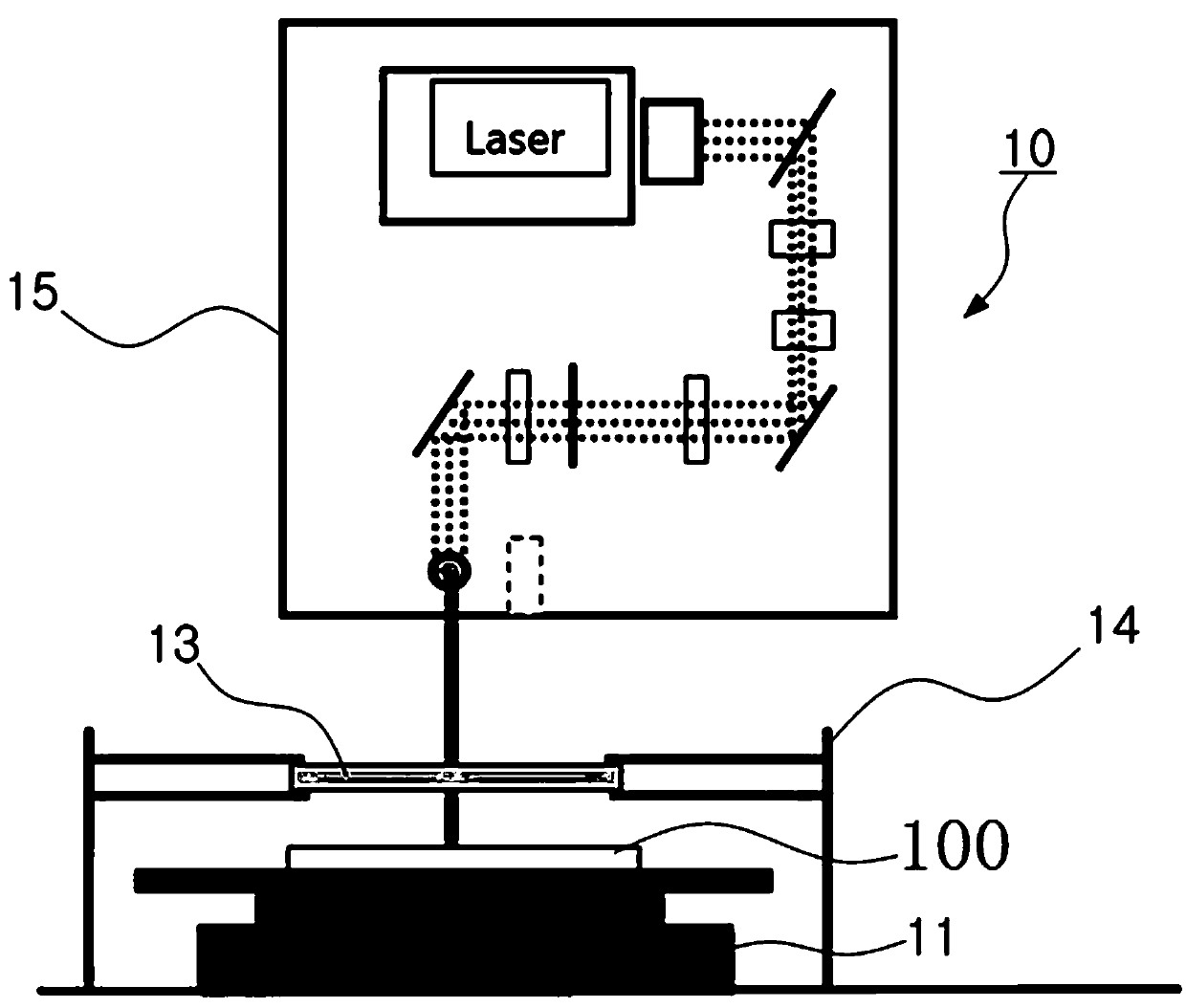

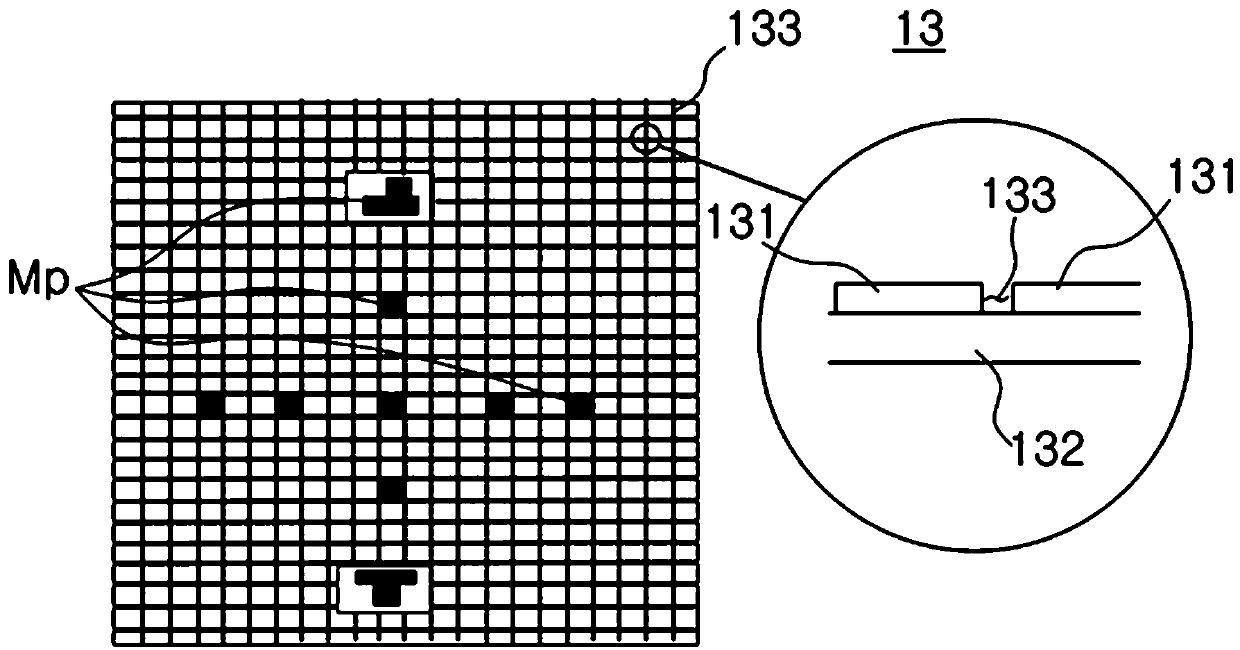

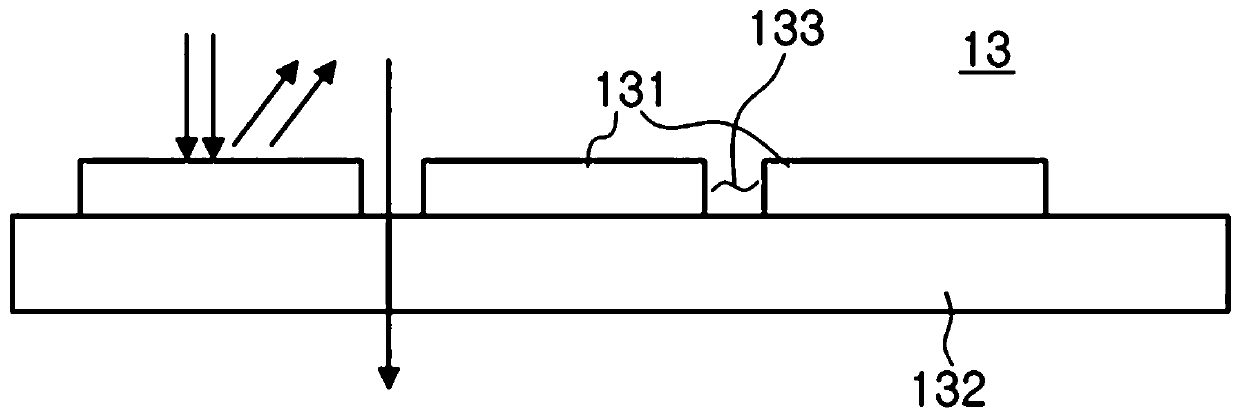

[0032] Such as Figure 1-6 As shown, the semiconductor wafer dicing device, the dicing device 10 includes a laser 15 and a wafer mold; Wafer carrier 11; the scribe mask includes a laser-permeable scribe area 133 and a blocking area 131 for laser blocking; the scribe area and the blocking area form a mask pattern; the mask The pattern includes the expected divided shape of the semiconductor wafer; when the wafer is divided, the laser of the laser passes through the scribed area of the dicing mask, and the wafer on the wafer carrier is cut according to the mask pattern.

[0033] The blocking area uses a frequency doubling material to block laser light from the laser.

[0034] The wafer carrier is movable so that the semiconductor wafer it carries is aligned with the mask pattern of the dicing mask.

[0035] The dicing device also includes an image system, which is used to align the preset positioning points on the wafer with the pattern positioning points of the mask pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com