A pressure adsorption type pole climbing robot

An adsorption, robot technology, applied in the direction of motor vehicles, transportation and packaging, can solve the problems of high failure rate, complex structure, difficult to control and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

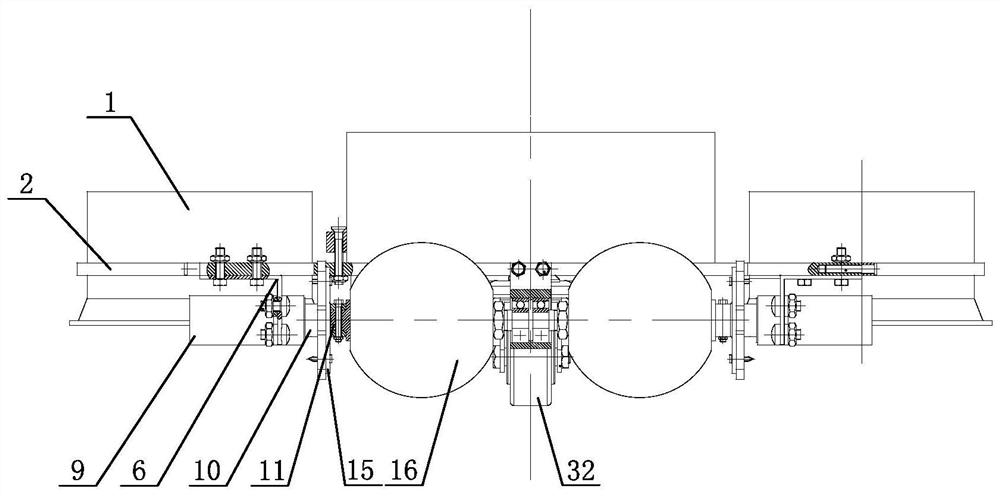

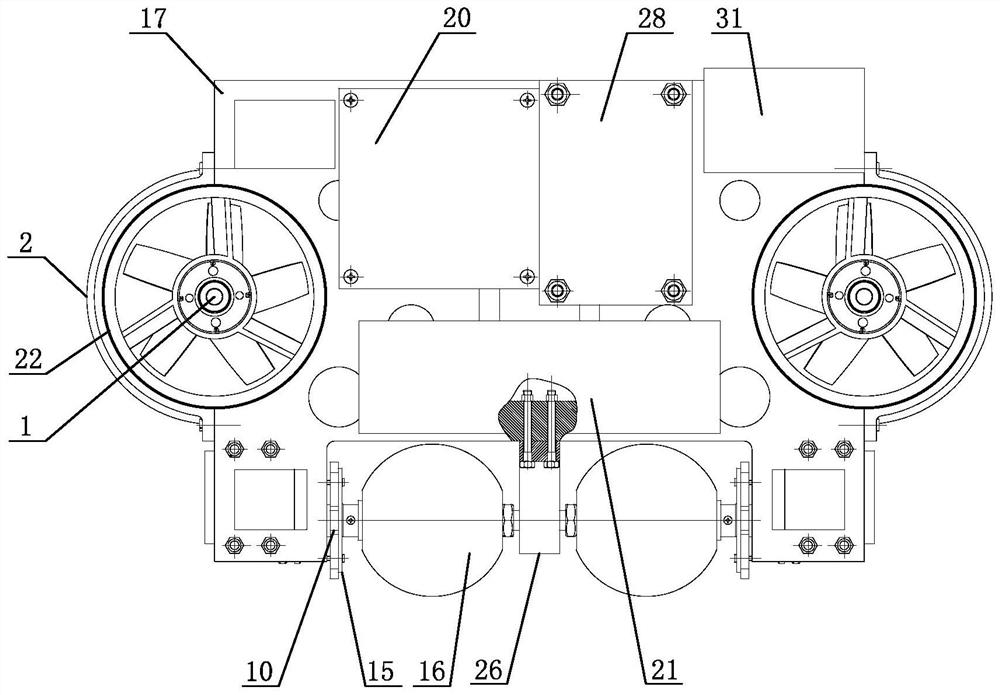

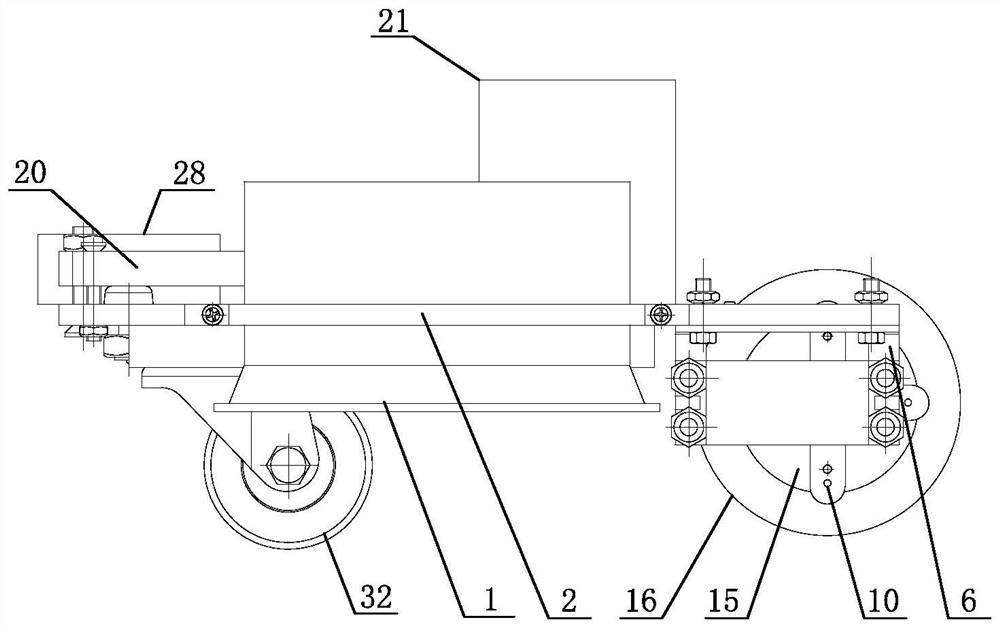

[0029] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment. In this embodiment, the pressure adsorption type pole climbing robot includes a fuselage 17, an electric control system, two drive mechanisms and two adsorption mechanisms. At the front end of the body 17, the pole-climbing robot realizes forward, backward and turning through two driving mechanisms. An adsorption mechanism is respectively arranged in the grooves on both sides of the fuselage 17, and the pole-climbing robot is adsorbed on the pole or vertical surface by two adsorption mechanisms. Above, the electronic control system is arranged on the fuselage 17 to control the two driving mechanisms and the two adsorption mechanisms.

[0030] The present invention realizes the pole climbing function by absorbing the thrust generated by the ducted fan and controlling the movement of the driving mechanism, the electric control system is greatly simplified, the structure is relatively...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination Figure 1 to Figure 5 Describe this embodiment, in this embodiment, each driving mechanism comprises steering gear 9, steering gear arm 10, flange plate 15, drive shaft 11, driving wheel 16 and steering gear bracket 6, and the front end middle position of fuselage 17 is set There are bearing blocks 26, two deep groove ball bearings are arranged side by side in the bearing blocks 26, the steering gear 9 is installed on the lower end surface of the fuselage 17 through the steering gear bracket 6, the steering gear arm 10 is mounted on the steering gear 9, the steering gear arm 10 and the flange 15 are fixedly connected by self-tapping screws, the drive wheel 16 is set on the drive shaft 11 and locked with a thin nut, and the flange 15 is fixedly connected with one end of the drive shaft 11 by a M1.4 screw. The other end of the drive shaft 11 is inserted in the deep groove ball bearing.

[0032] Among them, the steering gear i...

specific Embodiment approach 3

[0034] Embodiment 3: In this embodiment, the driving wheel 16 is a spherical wheel.

[0035] The wheel adopts a spherical shape, which can adapt to the arc of the rod, and also has certain adaptability to the diameter of the rod.

[0036] Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com