Closed type hypocycloid movable teeth speed reducer

A movable tooth reducer, hypocycloid technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of precision reducer not being self-sufficient, relying on imports, immature technology, etc. The effect of large ratio, low error sensitivity and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments do not limit the present invention in any way.

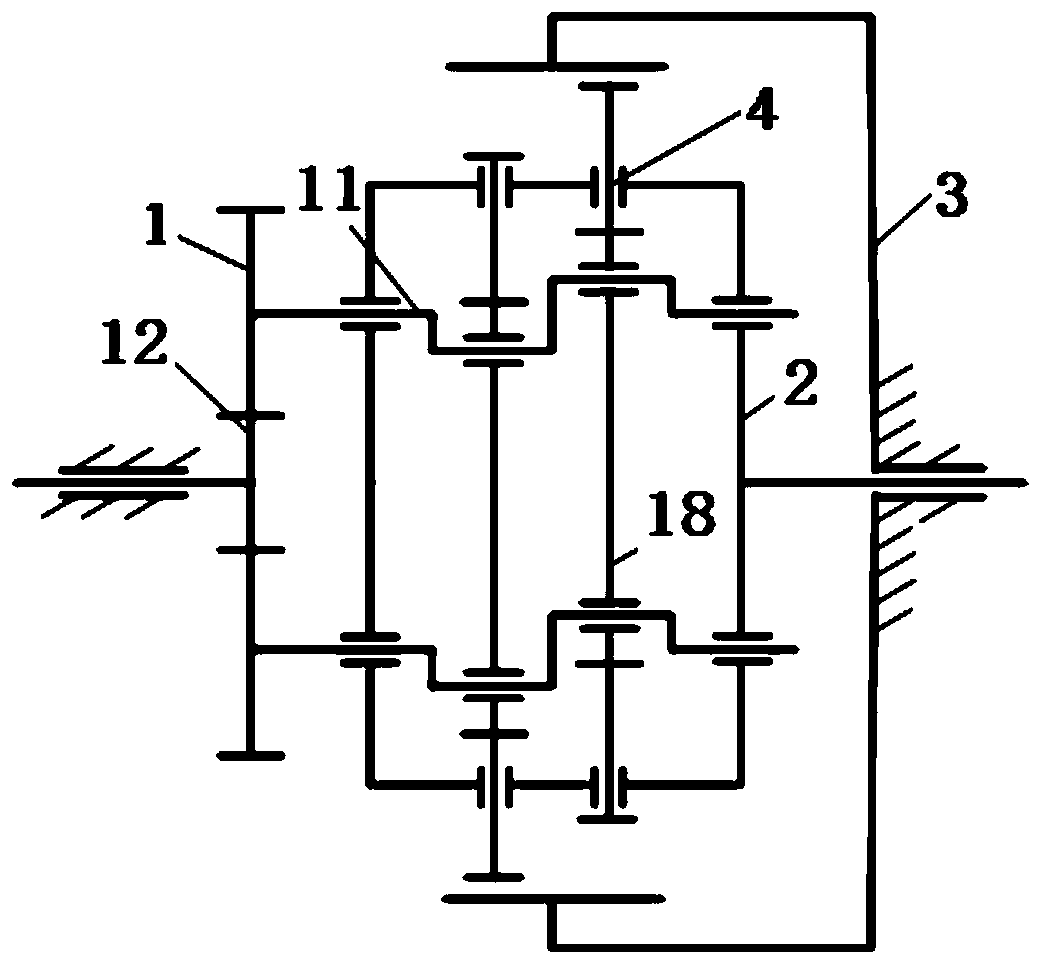

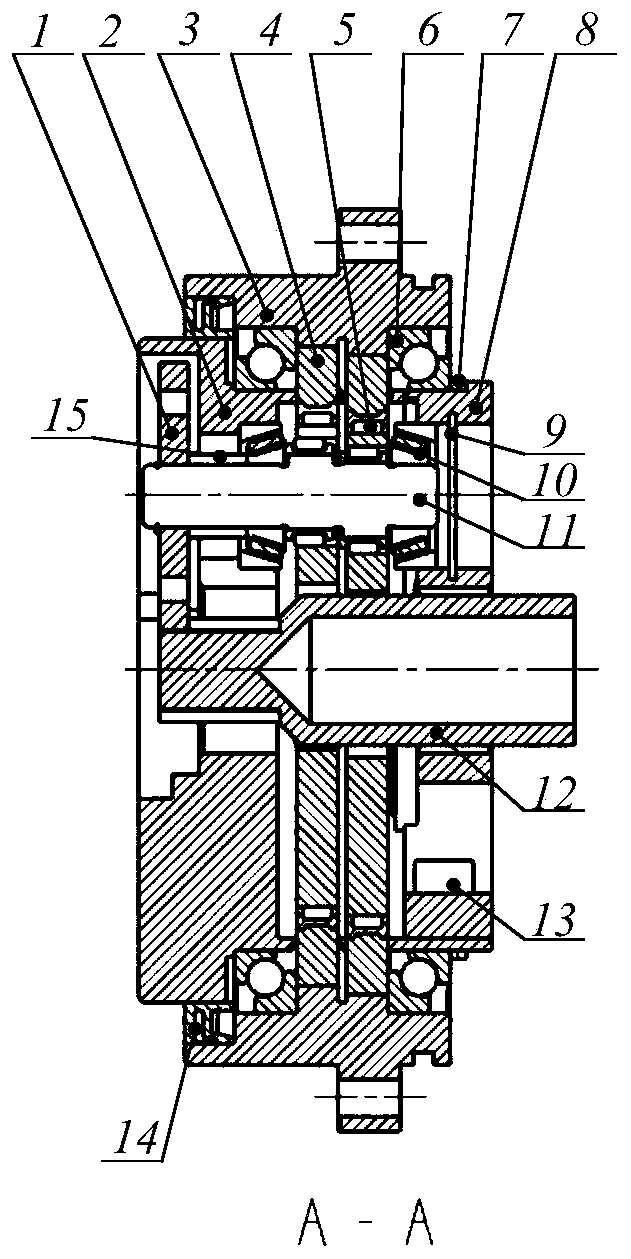

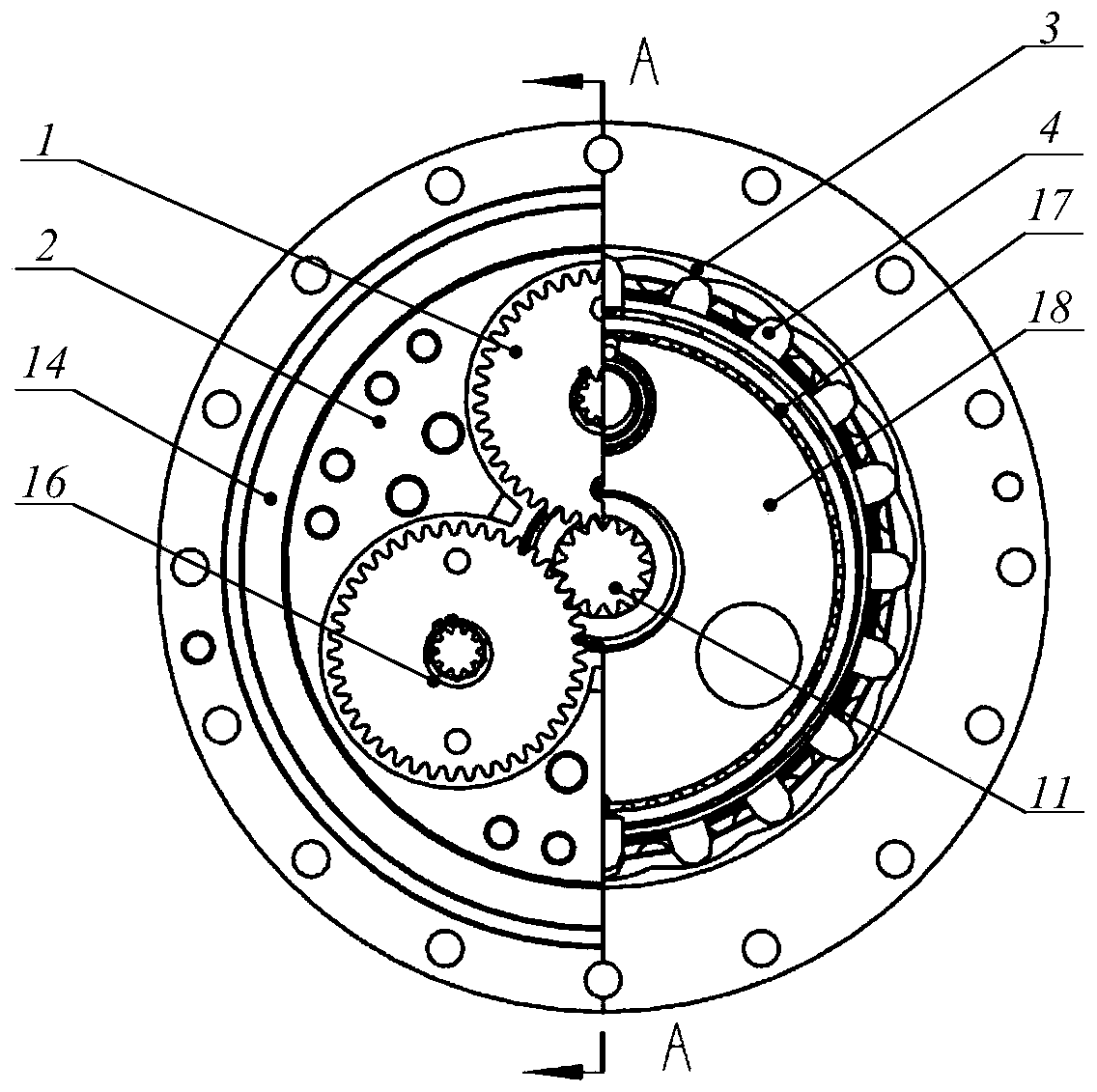

[0030] Such as figure 1 As shown, the present invention proposes a closed type hypocycloid movable gear reducer, including a high-speed stage and a low-speed stage, and the high-speed stage is composed of an input shaft 12, an involute center wheel 12 on the input shaft, three A K-H type planetary gear train composed of a circumferentially evenly distributed involute planetary gear 1, three crankshafts 11 and a planetary carrier. The planetary carrier is composed of an output disc 2 and a rigid disc 8 fixedly connected. The low-speed stage includes a planetary carrier and an eccentric disk shock wave device 18 that are fixedly connected with movable teeth 4, hypocycloid casing 3, output disk 2 and rigid disk 8; the three crankshafts 11, movable teeth 4, The hypocycloi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com