Slagging dedusting equipment for boiler in power plant

A technology for dust removal equipment and power plants, applied in the field of boilers, can solve problems such as inability to completely remove slag ash and low work efficiency, and achieve the effects of reducing non-processing time, improving work efficiency, and ensuring cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

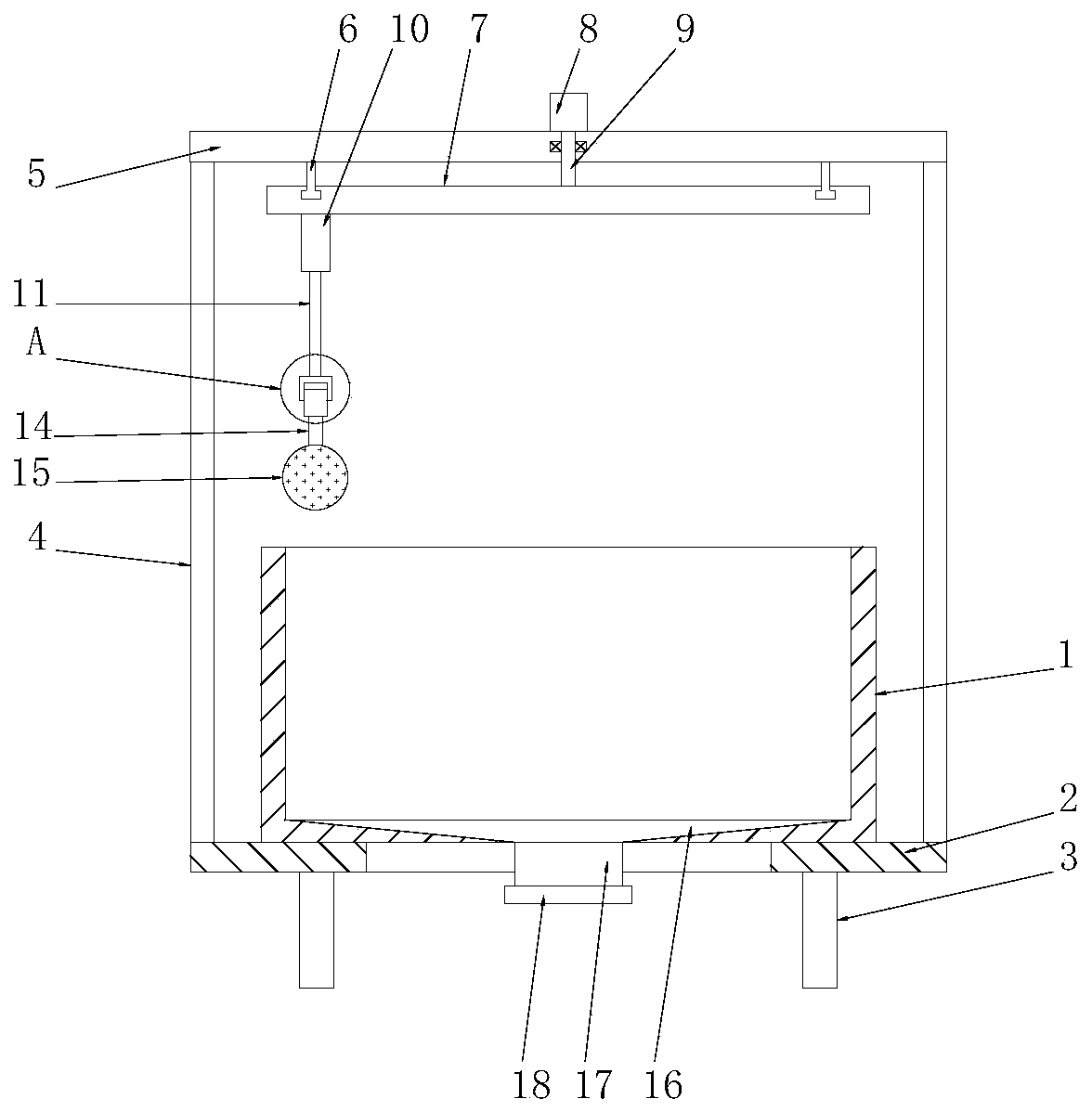

[0026] see Figure 1-3 , a boiler slag removal and dust removal equipment for a power plant, comprising a boiler body 1, a seat plate 2 is installed on the bottom end of the boiler body 1, the seat plate 2 is a ring structure, and the bottom end of the seat plate 2 is evenly installed with Several legs 3, the bottom end of the boiler body 1 is connected through the slag discharge pipe 17, the slag discharge pipe 17 is arranged in the inner cavity of the seat plate 2, the bottom end of the slag discharge pipe 17 is covered with a sealing cover 18, the boiler body The slag in the boiler body 1 is discharged through the slag discharge pipe 17, which is convenient for cleaning the slag in the boiler body 1.

[0027] The top of the seat plate 2 is evenly equipped with a number of uprights 4, and the tops of all the uprights 4 are jointly fixed with a top plate 5, and a feed mechanism is installed on the top plate 5, and a telescopic frame is installed on the feed mechanism. mechan...

Embodiment 2

[0030] This embodiment is a further elaboration on the basis of Embodiment 1. The feed mechanism includes a rotating motor 8, a slide rail 6 and a turntable 7. The rotating motor 8 is installed on the top of the top plate 5, and the slide rail 6 is installed At the bottom end of the top plate 5, the slide rail 6 is a ring structure, the rotating motor 8 is arranged on the axis of the slide rail 6, the turntable 7 is slidably connected to the slide rail 6, and the top of the turntable 7 is fixedly connected to the rotating shaft 9 The top of the rotating shaft 9 runs through the top plate 5 and is fixedly connected to the motor shaft of the rotating motor 8. The rotating shaft 9 and the top plate 7 are connected in rotation. The telescopic mechanism is installed on the bottom side of the turntable 7. 8 drives the rotating shaft 9 to rotate, and uses the rotating shaft 9 to drive the turntable 7 to rotate along the slide rail 6, thereby driving the telescoping mechanism to rotate...

Embodiment 3

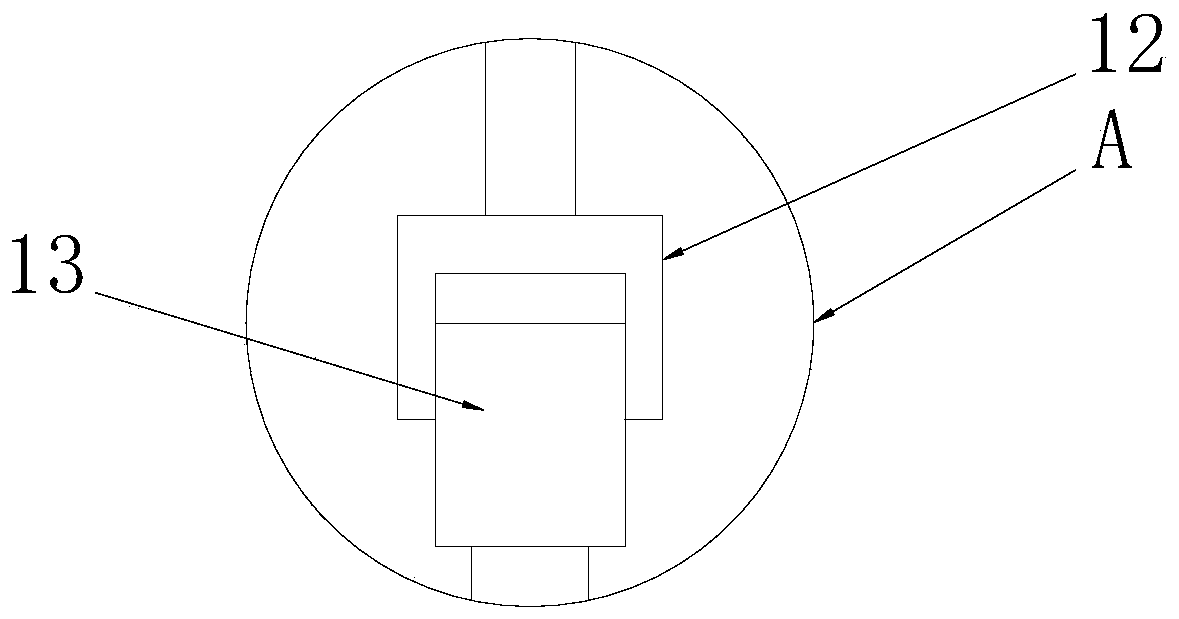

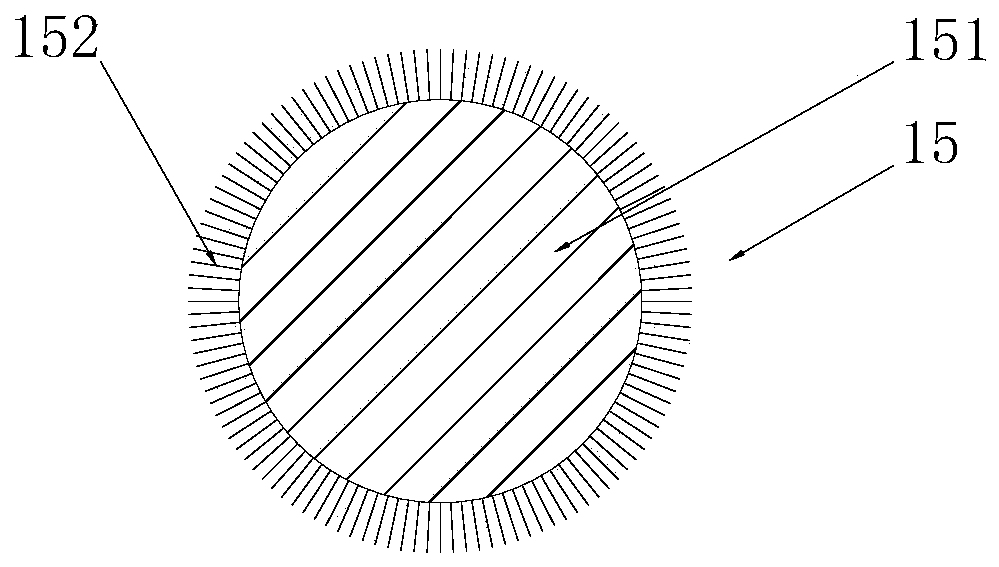

[0032]This embodiment is a further elaboration on the basis of Embodiment 1. The telescopic mechanism includes an electric telescopic rod 10, which is fixedly installed on the turntable 7, and the bottom end of the telescopic rod 11 on the electric telescopic rod 10 Fixed connection connecting frame 12, described connecting frame 12 is U-shaped structure, and cleaning motor 13 is installed in connecting frame 12, and the motor shaft of cleaning motor 13 is fixedly connected cleaning rod 14, and the bottom end of described cleaning rod 14 is fixedly installed with The scrubbing mechanism matched with the boiler body 1 stretches or retracts the telescopic rod 11 through the electric telescopic rod 10, so as to realize the use of the telescopic rod 11 to lower or lift the scrubbing mechanism, thereby completing the scrubbing mechanism entering or exiting the boiler body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com