Safe and efficient blasting construction method for vertical shaft well wall beam socket

A construction method and technology for well wall beam nests are applied in the field of safe and efficient blasting construction of shaft wall beam nests, which can solve the problems of low beam nest construction efficiency, high labor intensity, poor blasting effect, etc. Construction, the effect of reducing blasting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

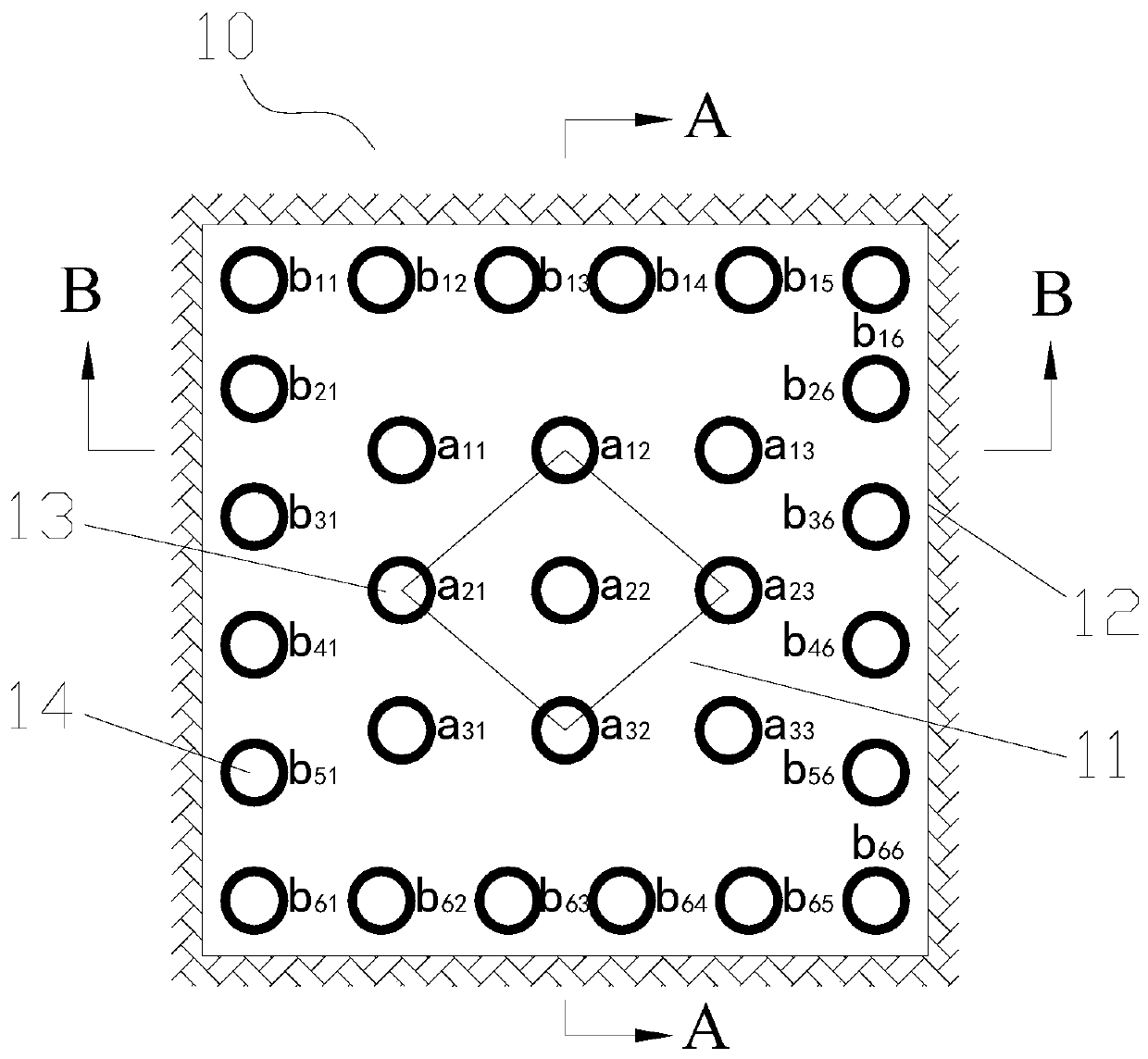

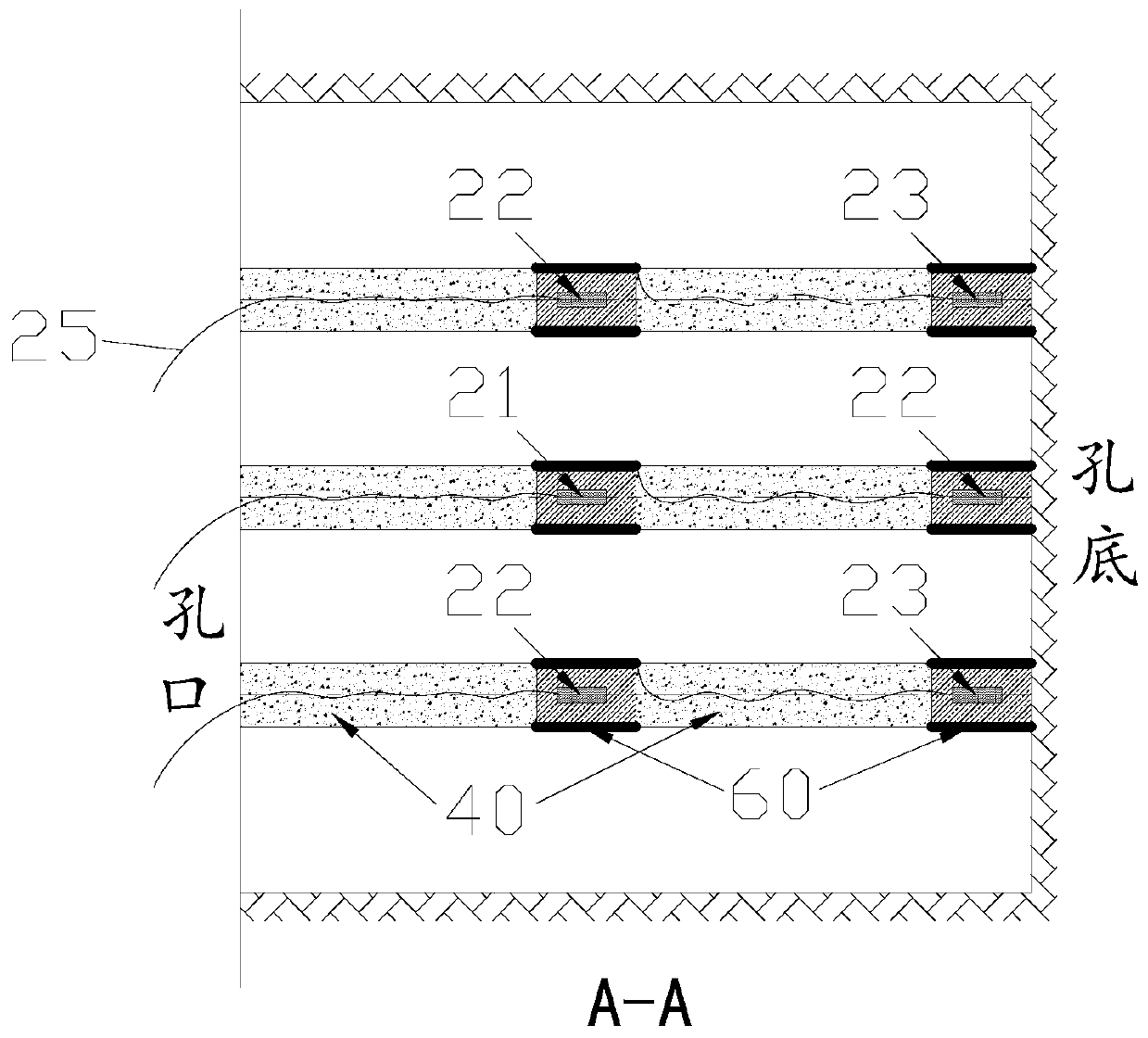

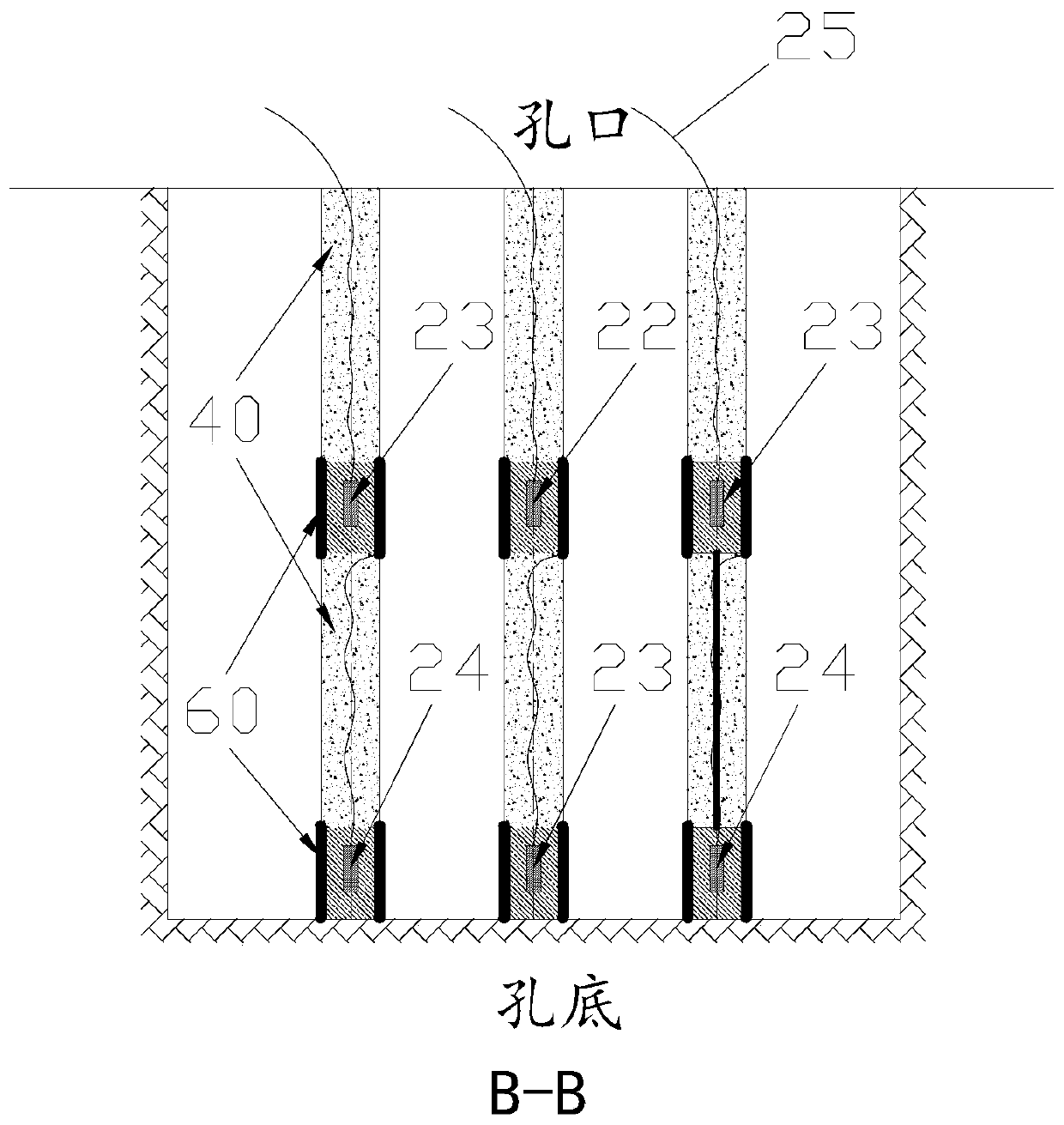

[0032] Such as Figure 1 to Figure 6 As shown, a safe and efficient blasting construction method for shaft wall beam nests, including:

[0033] A plurality of blastholes 13 distributed in an i×j matrix are opened in the main explosion zone 11 at the center of the beam nest 10, and the i×j matrix is written as Where i and j are both odd numbers and greater than or equal to 3; the most central The blastholes are used as the first group of blastholes, the nearest circle of blastholes on the periphery of the first group of blastholes is used as the second group of blastholes, and the nearest circle of blastholes on the periphery of the second group of blastholes is used as the third group of blastholes. By analogy, the charge form of each group of blastho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com