Heat-resistant enzymic preparation as well as preparation method and application thereof

A technology of enzyme preparation and porous adsorption material, applied in the field of heat-resistant enzyme preparation and its preparation, can solve the problems affecting the use effect of enzyme preparation, denaturation and inactivation of enzyme molecules, etc., achieve good biocompatibility and improve storage stability , the effect of blocking adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

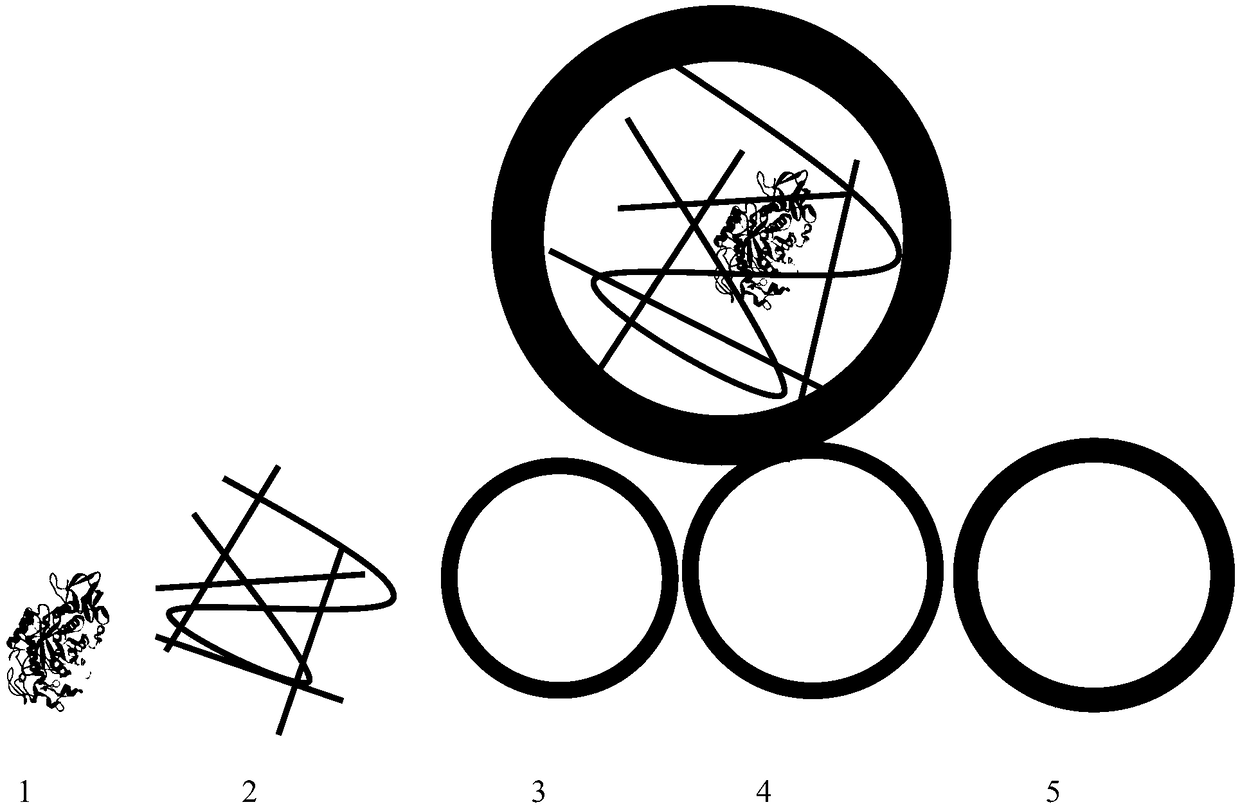

[0043] The present invention also provides the preparation method of the enzyme preparation, comprising the following steps: 1) mixing the enzyme molecule solution with the pulverized porous adsorption material, and absorbing to obtain the porous adsorption material adsorbed with enzyme molecules; 2) in step 1) The surface of the porous adsorption material adsorbed with enzyme molecules described in is coated with a polysaccharide layer, and after vacuum treatment, it is dried to obtain a core material; 3) the core material described in step 2) is coated with a hydrophobic layer to obtain a hydrophobic layer-coated core 4) In step 3), the core material coated with the hydrophobic layer is coated with the outer wall layer, and dried to obtain the enzyme preparation.

[0044] In the invention, the enzyme molecule solution is mixed with the pulverized porous adsorption material for adsorption to obtain the porous adsorption material adsorbed with enzyme molecules. In the present ...

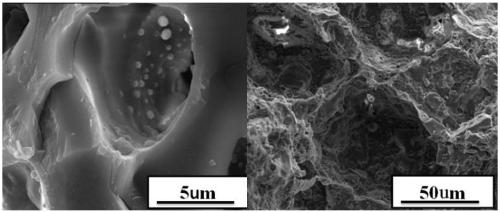

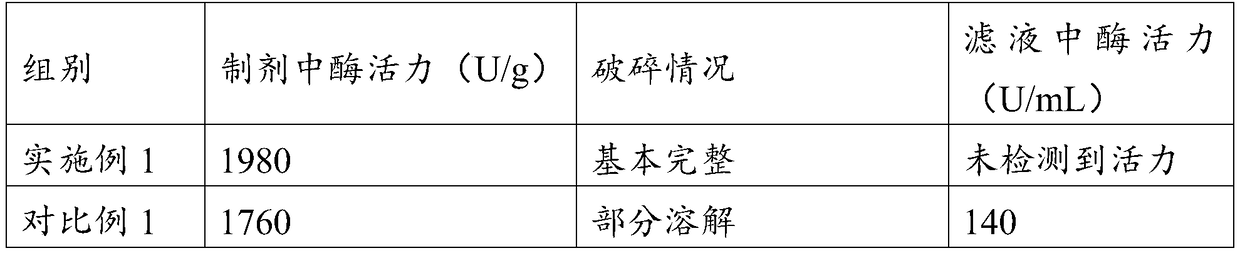

Embodiment 1

[0055] Take 10g of the quartz porous material and pulverize it to 80 mesh, and set it aside. Take 100mL of β-glucanase fermentation broth with an enzyme activity of 14600U / g, centrifuge at 3000rpm, 4°C for 10min, remove the precipitate, collect the supernatant and mix it with the pulverized quartz porous material, and centrifuge at 0.06MPa, 45°C Vacuum treatment for 20 minutes under certain conditions, to obtain a quartz porous material adsorbed with enzyme molecules.

[0056] Take 60 g of the quartz porous material adsorbed with enzyme molecules and suspend it in the fluidized bed. Take 3.2g of gum arabic and 6.4g of maltodextrin to prepare 48mL of polysaccharide aqueous solution, and coat the quartz porous material adsorbed with enzyme molecules at a spray speed of 1.2mL / min; after the coating is completed, keep the flowing state for 5min; Vacuum-process the above-mentioned material in wet state for 20min under the conditions of 0.06MPa and 45°C. After vacuum treatment, dr...

Embodiment 2

[0062] Take 4g of sepiolite and crush it to 80 mesh, set aside. Take 100mL of the fermented supernatant β-glucan enzyme solution with an enzyme activity of 14600U / g, mix it with the crushed sepiolite above, and treat it under vacuum at 0.06MPa and 45°C for 5min. Centrifuge at ℃ for 10 min, remove the supernatant, and obtain sepiolite with enzyme molecules adsorbed thereon.

[0063] Take 80 g of the porous adsorption material adsorbed with enzyme molecules and suspend it in the fluidized bed. Take 3.75g of gum arabic and 3.75g of maltodextrin to prepare 62.5mL of polysaccharide aqueous solution, and coat the porous adsorption material with enzyme molecules at a spray speed of 1mL / min; after the coating is completed, add 2g of talcum powder to keep Flowing state for 5 minutes; the above material in wet state was vacuum treated for 15 minutes under the conditions of 0.04MPa and 40°C. After vacuum treatment, dry at 40°C and normal pressure for 15 minutes, then transfer to a vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com