Thermo-sensitive polymer-based hollow fiber and hollow microsphere as well as preparation method and application thereof

A temperature-sensitive polymer and polymer technology, applied in the manufacture of hollow filaments, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve the problems of slow response rate, limited use effect, large size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

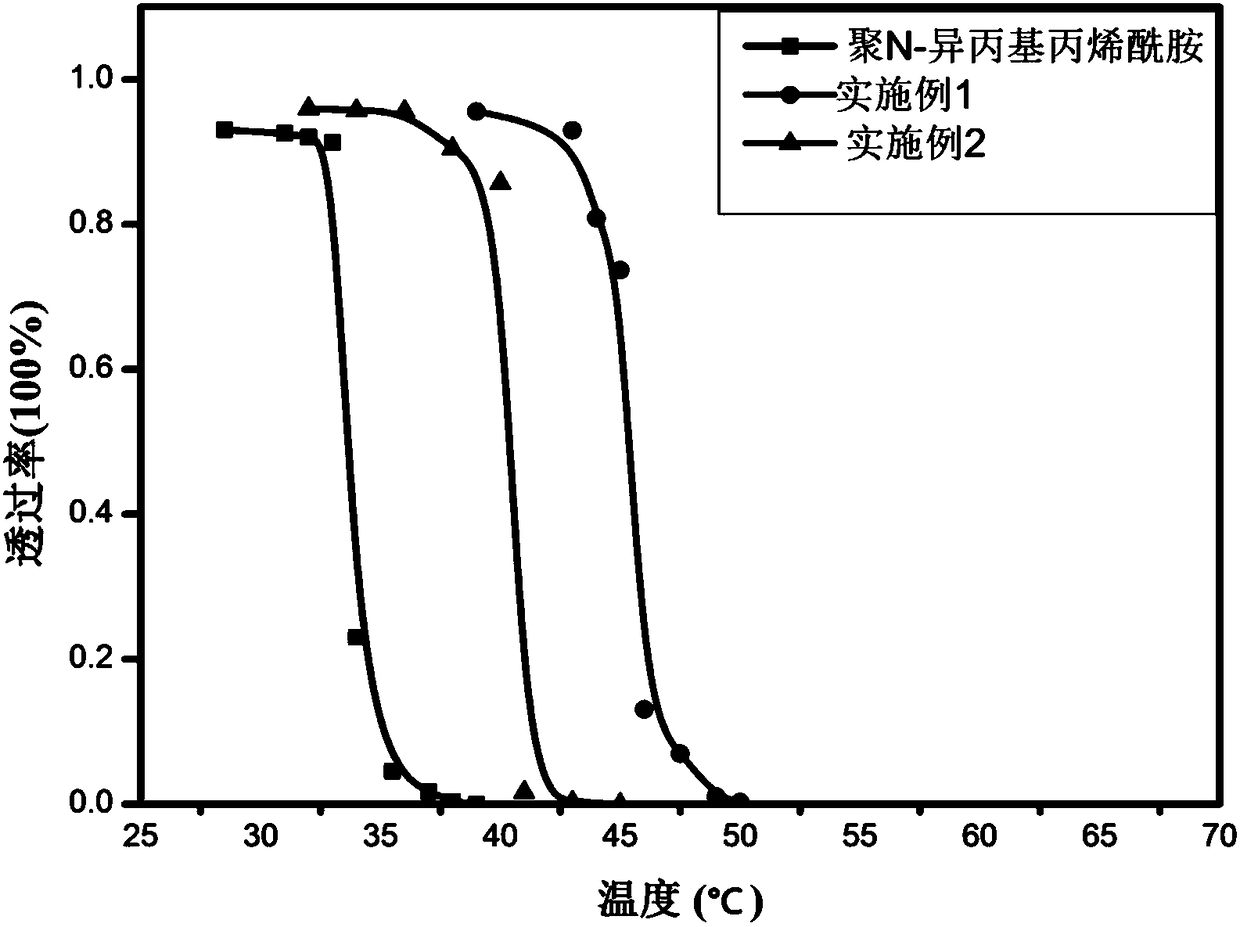

Embodiment 1

[0038] 1. Preparation of temperature sensitive polymer (poly N-isopropyl acrylamide / N-methylol acrylamide / acrylamide polymer):

[0039] Add 20 parts of acrylamide, 70 parts of N-isopropylacrylamide, and 10 parts of N-methylolacrylamide into deionized water. The reaction materials (acrylamide+N-isopropylacrylamide+N-methylolpropylene) The total concentration of amide) is 20wt%. After the raw materials are completely dissolved, the initiator potassium persulfate is added (the quality of the initiator is one percent of the weight of the raw materials), and the prepolymerization is carried out in a water bath at 0°C for 4h (avoid N- Isopropylacrylamide self-crosslinking), and then reacted in an environment at a temperature of 60℃ for 6h to obtain a poly-N-isopropylacrylamide polymer solution; then dialysis treatment for 48h, changing the deionized water every 12 hours ; Finally, freeze-drying to obtain a water-soluble temperature-sensitive polymer-poly N-isopropyl acrylamide / N-methyl...

Embodiment 2

[0045] 1. Preparation of temperature-sensitive polymer (poly N-isopropylacrylamide / isobutoxy methacrylamide / acrylic acid polymer):

[0046] Add 10 parts of acrylic acid, 80 parts of N-isopropyl acrylamide, and 10 parts of isobutoxy methacrylamide into dimethylformamide. The reaction materials (acrylic acid + N-isopropyl acrylamide + isobutyl The total concentration of oxymethacrylic acid amine) is 16wt%. When the reaction raw materials are completely dissolved, add the initiator ammonium persulfate (the initiator accounts for 3% of the total mass of the reaction raw materials), and place it in a water bath at -5°C. Prepolymerize for 3h (to avoid self-crosslinking of N-isopropylacrylamide), then react for 8h in an environment at a temperature of 50℃ to obtain a polymer solution (poly N-isopropylacrylamide polymer solution); then dialyze Treated for 96 hours, change the deionized water every 12 hours; finally freeze-dry to obtain a water-soluble temperature-sensitive polymer—poly N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com