Numerical control machine tool thermal coupling error modeling and compensation method considering machining parameters

A numerical control machine tool and thermal-mechanical coupling technology, applied in the direction of comprehensive factory control, simulator, program control, etc., can solve problems such as complex methods, poor operability, and low portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

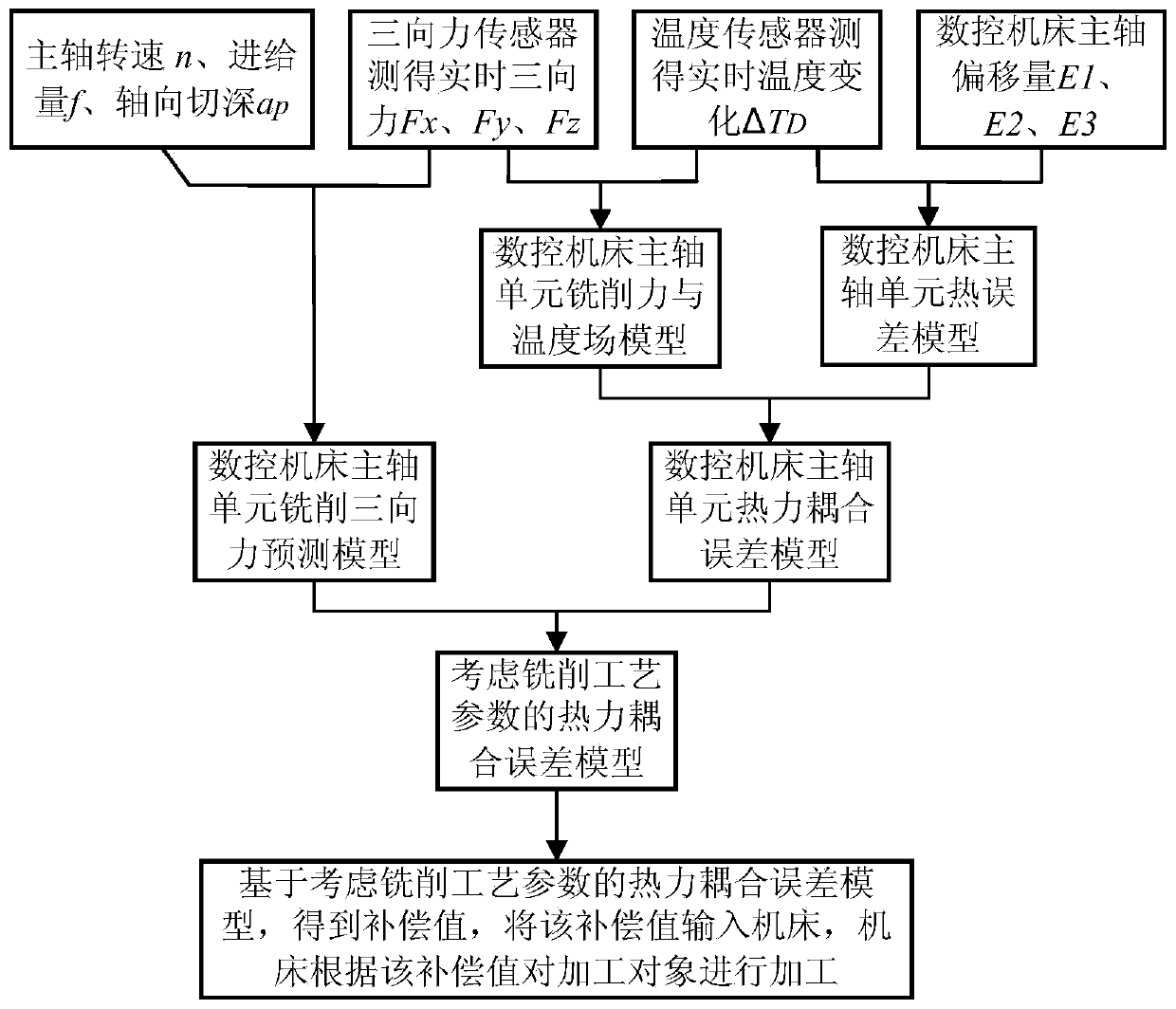

[0033] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples, a numerically controlled machine tool thermomechanical coupling error modeling and compensation method considering processing parameters, such as figure 1 As shown, the specific steps are as follows:

[0034]Step 1. Build a load milling error test platform based on the LabView data acquisition system, and use a temperature sensor to measure the spindle temperature change ΔT D , the real-time three-way force F is measured by the three-way force sensor X , F Y , F Z , the spindle offset E measured by the laser displacement sensor 1 ,E 2 ,E 3 Experimental data;

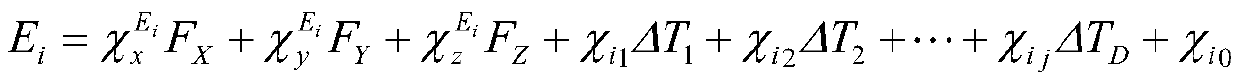

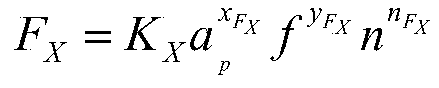

[0035] Among them, the process parameters of the load milling test include the axial depth of cut a p , feed per tooth f, spindle speed n; CNC machine tool spindle offset E 1 ,E 2 ,E 3 , where E 1 ,E 2 is the radial error offset of the main shaft, E 3 is the axial error off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com