Smoke generation section for constituting smoke generation system

A generation system and technology of the generation department, applied in the fields of application, tobacco, smoker's supplies, etc., can solve the problems of cumbersome preparation methods and operation processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

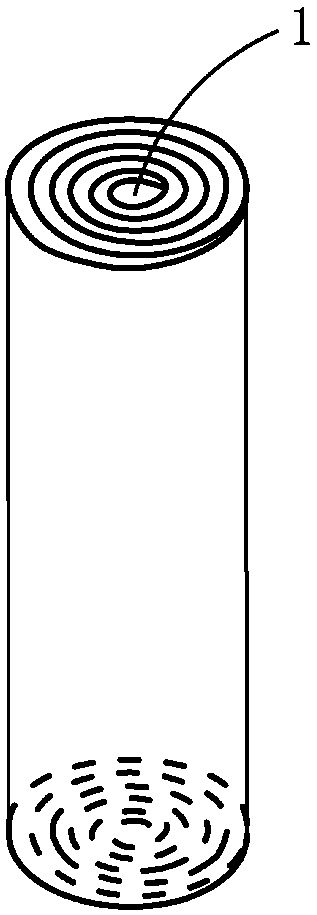

[0031] A flue gas generating section used to form a flue gas generating system. The cylinder body is composed of several hollow pipe bodies with different pipe diameters stacked on the same axis; the outer diameter of the cylinder body is 6-10mm, and the length is 10- 50mm; the coaxial tubular cavity (central tube body) at the center has a diameter of 1-3mm and a length of 10-50mm, and is compatible with the size and specification of the central heating element.

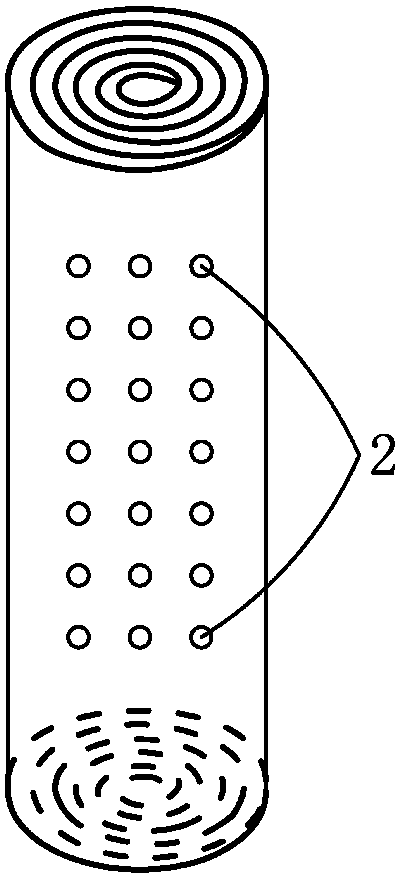

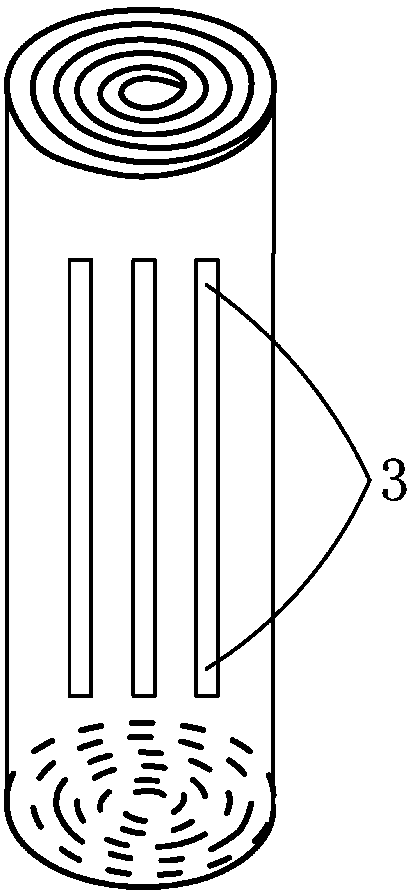

[0032] The pipe body is composed of thin slices connected end to end, and the thin slices are provided with a plurality of circular and / or slit-shaped heat convection holes. And preferably, the heat convection holes are arranged axially, and the heat convection holes of the same horizontal section penetrate from the outer surface of the cylinder to the center of the circle.

[0033] If the thermal convection hole is circular, the diameter is 0.2-1mm, the interval is 1-4mm, and the density is 4-25 / cm 2 .

[0034] If...

Embodiment 2

[0039] A smoke generating section used to form a smoke generating system. The cylinder is composed of several thin slices connected end to end in a spiral shape, and the center is a coaxial tubular cavity; the diameter of the outer ring is 6-10mm, and the length is 10-50mm, the diameter of the coaxial tubular cavity at the center is 1-3mm, and the length is 10mm-50mm, which is compatible with the size and specification of the central heating element. Preferably, several flakes are a whole large flake.

[0040] Several circular and / or slit-shaped heat convection holes are arranged on the sheet. And preferably, the heat convection holes are arranged axially, and the heat convection holes of the same horizontal section penetrate from the outer surface of the cylinder to the center of the circle.

[0041] If the thermal convection hole is circular, the diameter is 0.2-1mm, the interval is 1-4mm, and the density is 4-25 / cm 2 .

[0042] If the thermal convection holes are slot-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com