Vacuum sucker type pick-up manipulator

A technology of vacuum suction cups and manipulators, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., which can solve the problems of increased equipment cost, increased installation difficulty, and affecting the speed of the second sheet of material, so as to achieve simple installation and reduce safety. Hidden dangers, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

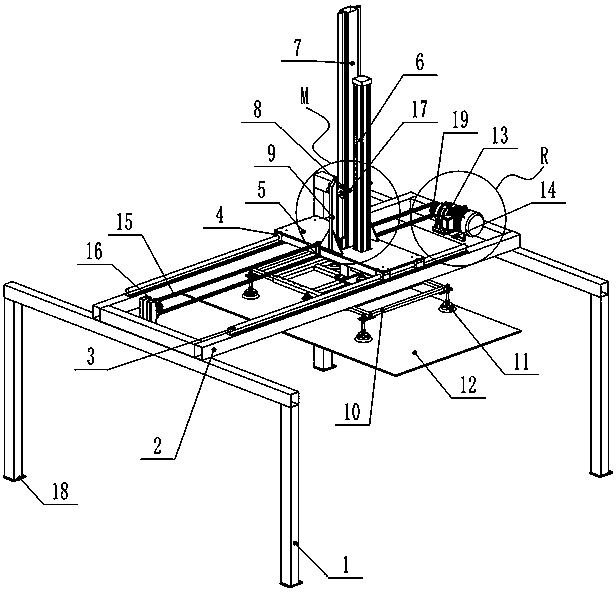

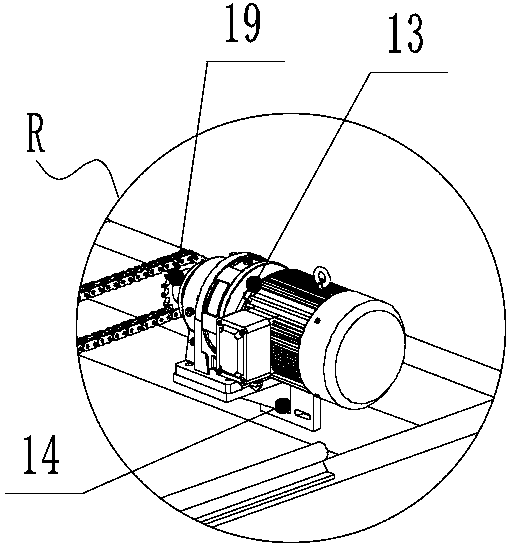

[0030] Embodiment 1 Vacuum suction cup type pick-up manipulator

[0031] see Figure 1~8 , the present invention provides a vacuum suction cup-type picking manipulator, comprising a fixed bracket 1, two fixed brackets 1 are symmetrically arranged, and a picking gantry 2 is arranged horizontally on the two fixing brackets 1, and the picking gantry 2 is rectangular border structure.

[0032] The bottom of the fixed bracket 1 is provided with a fixed bracket adjusting plate 18, and the fixed bracket adjusting plate 18 is provided with an adjusting hole. An anchor bolt can be arranged in the adjustment hole to fix the fixing bracket 1 on the ground.

[0033] Both the fixed bracket 1 and the pick-up gantry 2 are composed of square tubes with a side length of 100 mm.

[0034] The frame where the two corresponding long sides on the picking gantry 2 is located is provided with a transverse slide rail 3,

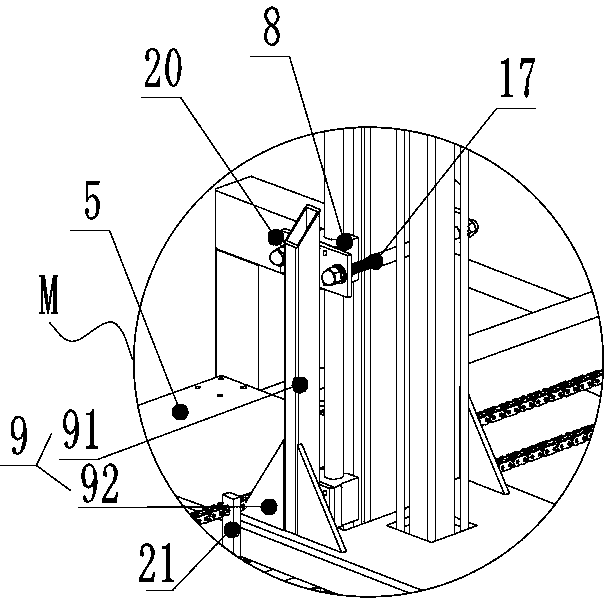

[0035] It also includes a column to pick up and fix the plate 5, and the col...

Embodiment 2

[0058] Embodiment 2 Vacuum suction cup type pick-up manipulator

[0059] The present invention also provides a vacuum chuck-type picking manipulator, which is different from the above-mentioned embodiment in that: the fixed mounting plate 9 of the slider includes two symmetrically arranged base plates 91, and right-angles are arranged on both sides of the bottom of each base plate 91 The triangular fixing plate 92 and the right-angled triangular fixing plate 92 can more firmly fix the base plate 91 on the column pick-up fixing plate 5, so that it is not easy to shake.

[0060] The base plate 91 is a rectangular tube, and the top of the base plate 91 is an inclined incision, and the incision is downward from the side close to the central axis of the column picking up the fixing plate 5 to the side away from the central axis of the column picking up the fixing plate 5 Tilt setting. The oblique setting of the cutout can ensure the convenience of observing the conditions on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com