Locking structure and tensioning holding component and implementation method and tensioning device for prestressed tendons

A technology for retaining parts and locking structures, applied in the field of rail transit, can solve the problems of frequent replacement of tension retaining structures, failure of friction wheel friction walls, and impact on the performance of track plates, and achieves good effects, increased service life, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

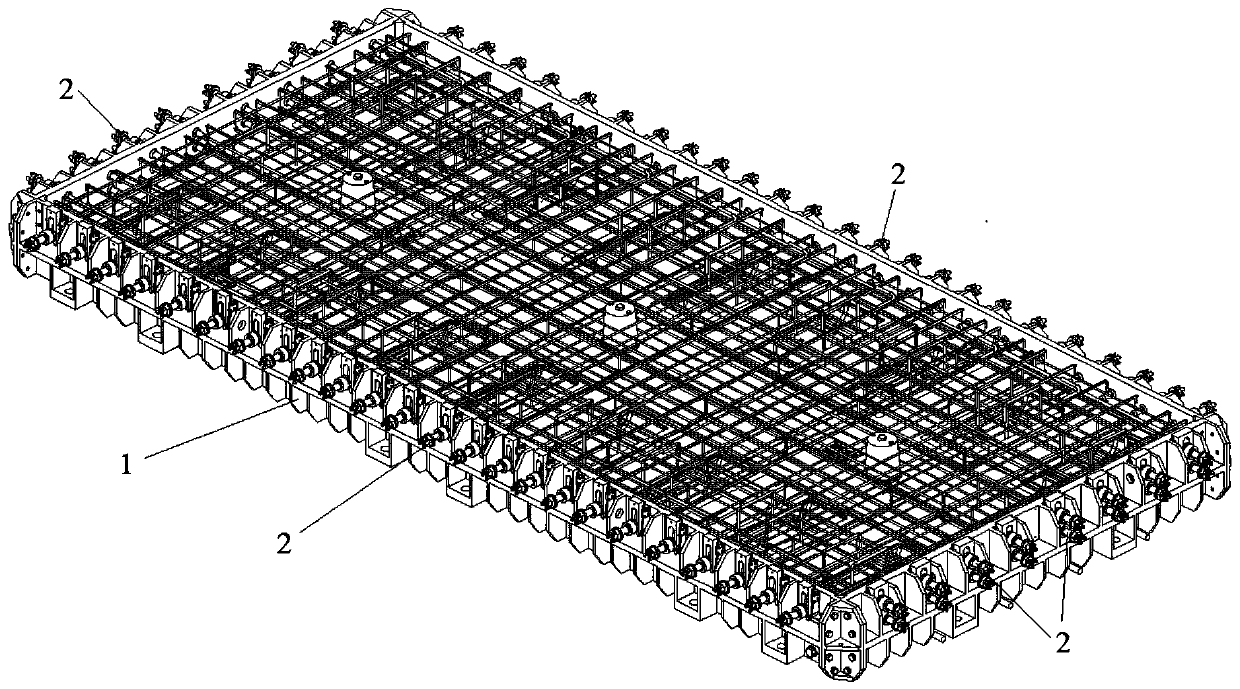

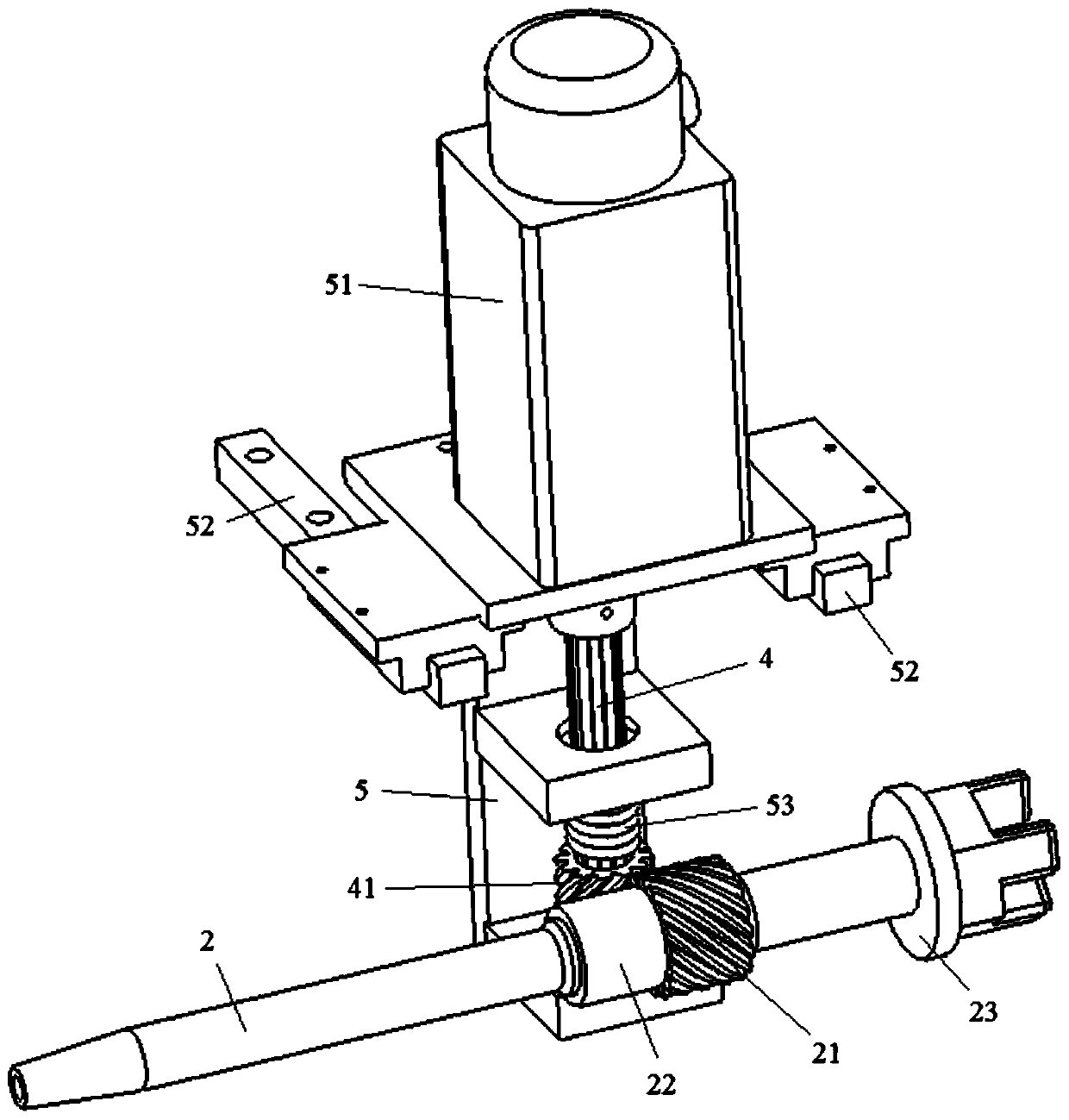

[0074] like Figure 3-5 As shown, a locking structure of the present invention includes a helical gear nut 21 and a helical gear 41 capable of meshing with it. The helical gear nut 21 is a round nut with internal threads, and the outer wall of the round nut is provided with helical teeth. .

[0075] The helical gear nut 21 is used to be threadedly connected to the component to be locked, the axis of the helical gear nut 21 and the axis of the helical gear 41 are arranged perpendicular to each other, and the helical gear 41 is used to drive the helical gear nut 21 to rotate , the helical gear 41 can move along its axial direction.

[0076] The locking structure is realized in such a way that the helical gear nut 21 and the helical gear 41 engage and rotate, and the helical gear nut 21 rotates to the component to be locked along its axial direction, when the helical gear nut After 21 fits on the parts to be locked, that is, after reaching the locked state, the helical gear nut...

Embodiment 2

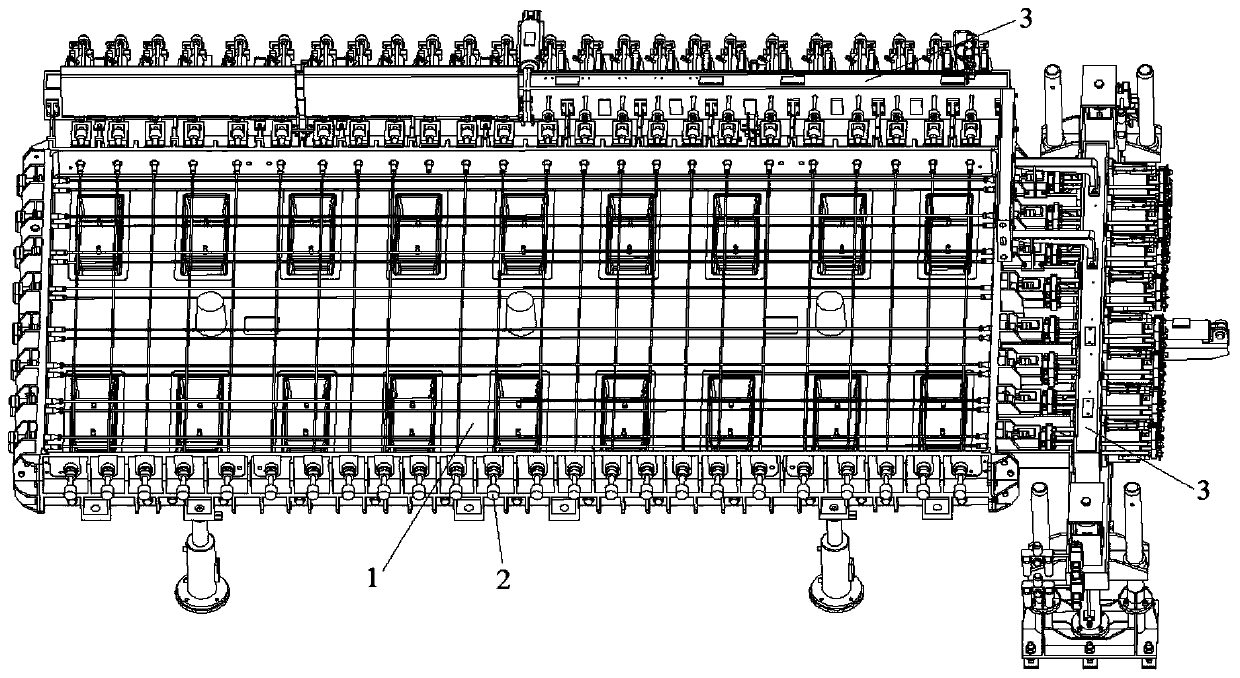

[0079] like Figure 3-6 As shown, a prestressed tendon tension holding part according to the present invention includes a locking structure as described in Embodiment 1, a rotating shaft 4, a base 5, a first drive assembly 51, a slide rail 52, a first Two driving components and an elastic mechanism 53, the helical gear nut 21 is used to be threadedly connected to the external thread section 22 of the tension rod 2.

[0080] The helical gear 41 is slidably socketed on the rotating shaft 4, the rotating shaft 4 can drive the helical gear 41 to rotate, the first driving assembly 51 is arranged on the base 5, and the rotating shaft 4 is arranged on The base 5 is connected to the output end of the first drive assembly 51, the first drive assembly 51 is used to drive the rotation of the rotating shaft 4, and the base 5 is slidably adapted to the slide rail 52, the second drive assembly is connected to the base 5 and drives the base 5 to move along the slide rail 52, and one end of ...

Embodiment 3

[0088] like Figure 3-6 As shown, a method for realizing tension retention of prestressed tendons according to the present invention uses the tension retention components as described in Embodiment 2, comprising the following steps:

[0089] A. Pulling the tension rod 2 drives the tensioning of the prestressed steel bars;

[0090] B. The first drive assembly 51 drives the rotating shaft 4 to rotate, so that the helical gear 41 rotates, and the second drive assembly drives the base 5 to move along the slide rail 52, so that the helical gear 41 Close to the helical gear nut 21;

[0091] C. The helical gear 41 meshes with the helical gear nut 21, and the helical gear nut 21 rotates along the external thread section 22 and rotates to the wall of the track plate mold 1;

[0092] D. The helical gear nut 21 is attached to the wall of the track plate mold 1, the helical gear nut 21 stops rotating, the helical gear 41 is in a rotating state, and the helical teeth on the helical gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com