Pressing device of fluorite ball

A technology of fluorite balls and transportation devices, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve problems such as solution deformation, cracking, and affecting the quality of fluorite balls, so as to improve quality and avoid deformation or cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

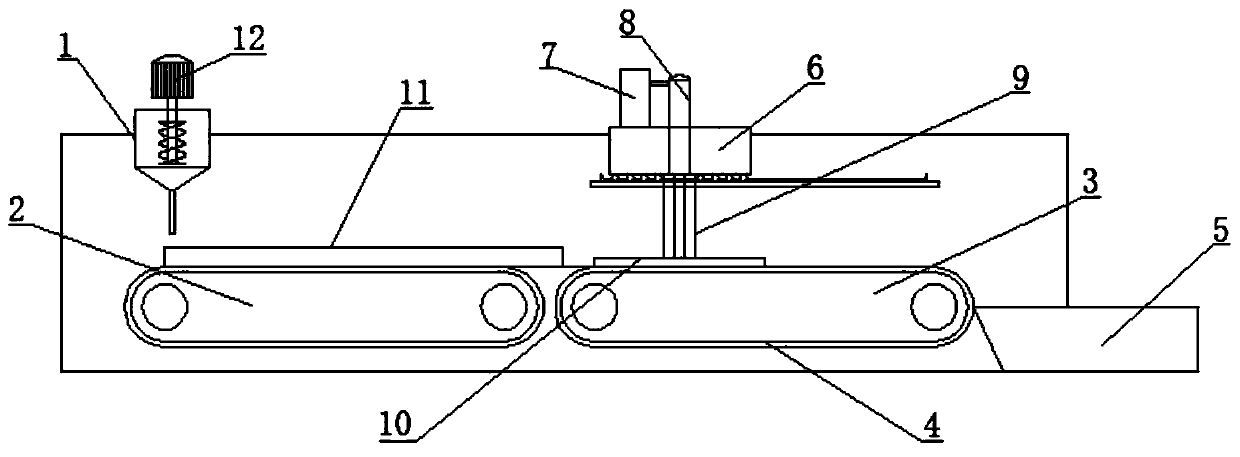

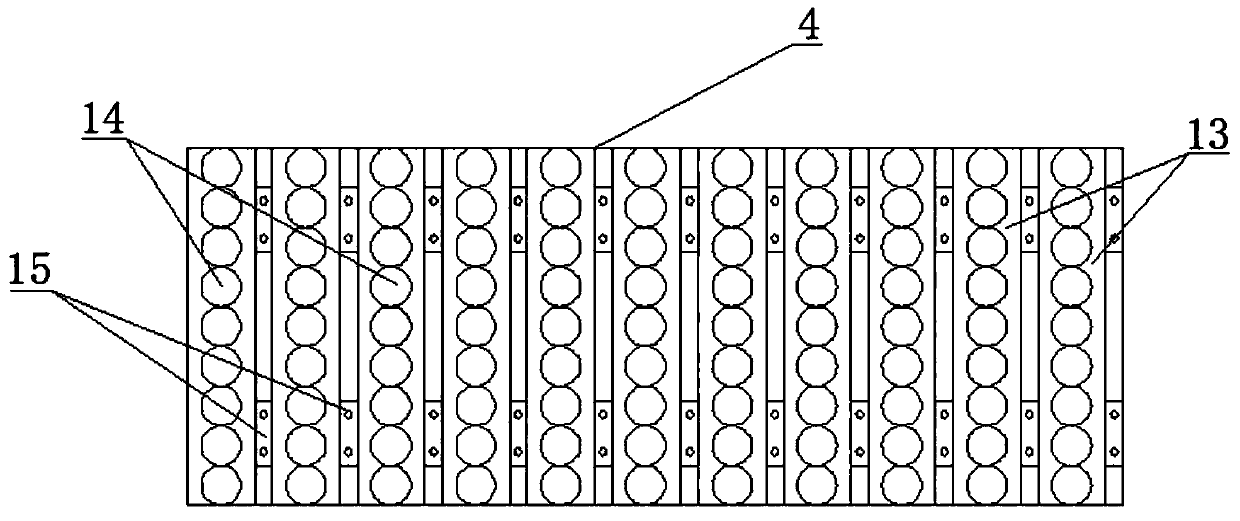

[0030] Such as Figure 1-5 As shown, a pressing device for fluorite balls, the front end of the pressing device is provided with a feeding hopper 1, the bottom of the feeding hopper 1 is provided with a mud paste transport device 2, and the right side of the mud paste transport device 2 A pressing transportation device 3 is arranged on the side, and a pressing bottom mold 4 is arranged on the pressing transportation device 3 , and a fluorite ball collection tank 5 is arranged on the right side of the pressing transportation device 3 .

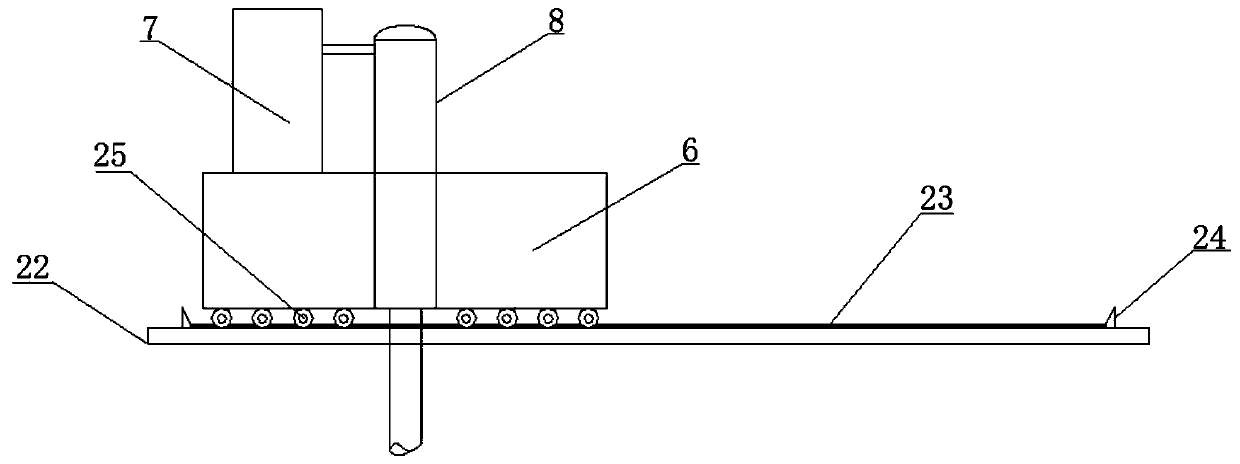

[0031] Further, the upper part of the pressing transportation device 3 is provided with a pressing upper mold 10, the upper end of the pressing upper mold 10 is connected to the transmission hydraulic cylinder 8, and the transmission hydraulic cylinder 8 is connected to the pressing hydraulic tank 7, and the pressing hydraulic tank 7 And the transmission hydraulic cylinder 8 is installed on the stepping drive device 6, and the upper end surface...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] The pressing bottom template 13 is provided with a pressing lower groove 14 and the pressing upper template 16 is provided with a pressing upper groove 17, which are all configured as conical grooves, pyramidal grooves, rounded truncated grooves, and knife-edge truncated grooves. One or a combination of several slots.

Embodiment 3

[0049] The difference between this embodiment and the embodiment is:

[0050] The electric heating wire 9 is arranged to be connected with the pressing bottom template 13, and the side parts of each pressing bottom template 13 are connected by the electric heating wire 9;

[0051] The interior of the pressing bottom template 13 is provided with a cavity, and an electric heating tube 19 is provided in the cavity;

[0052] The electric heating tube 19 is connected with the electric heating wire 9 arranged on the pressing bottom template 13;

[0053]The interior of the pressed bottom template 13 is filled with a liquid medium 20 for conducting heat;

[0054] A liquid inlet 21 is provided on the side of the pressing bottom template 13 , and the liquid medium 20 enters the pressing bottom template 13 through the liquid inlet 21 .

[0055] When working, all the mixed raw materials added to the fluorite balls are put into the feeding hopper 1, and the stirring motor 12 is started, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com