Injection molding and blow molding combined type forklift tray with high bearing strength

A high-load, combined technology, used in transportation and packaging, rigid containers, containers, etc., to achieve the effect of predicting in advance, good impact resistance, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

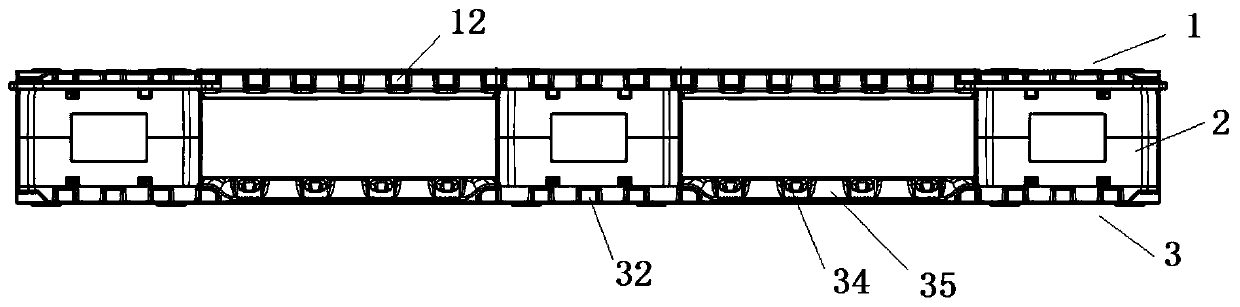

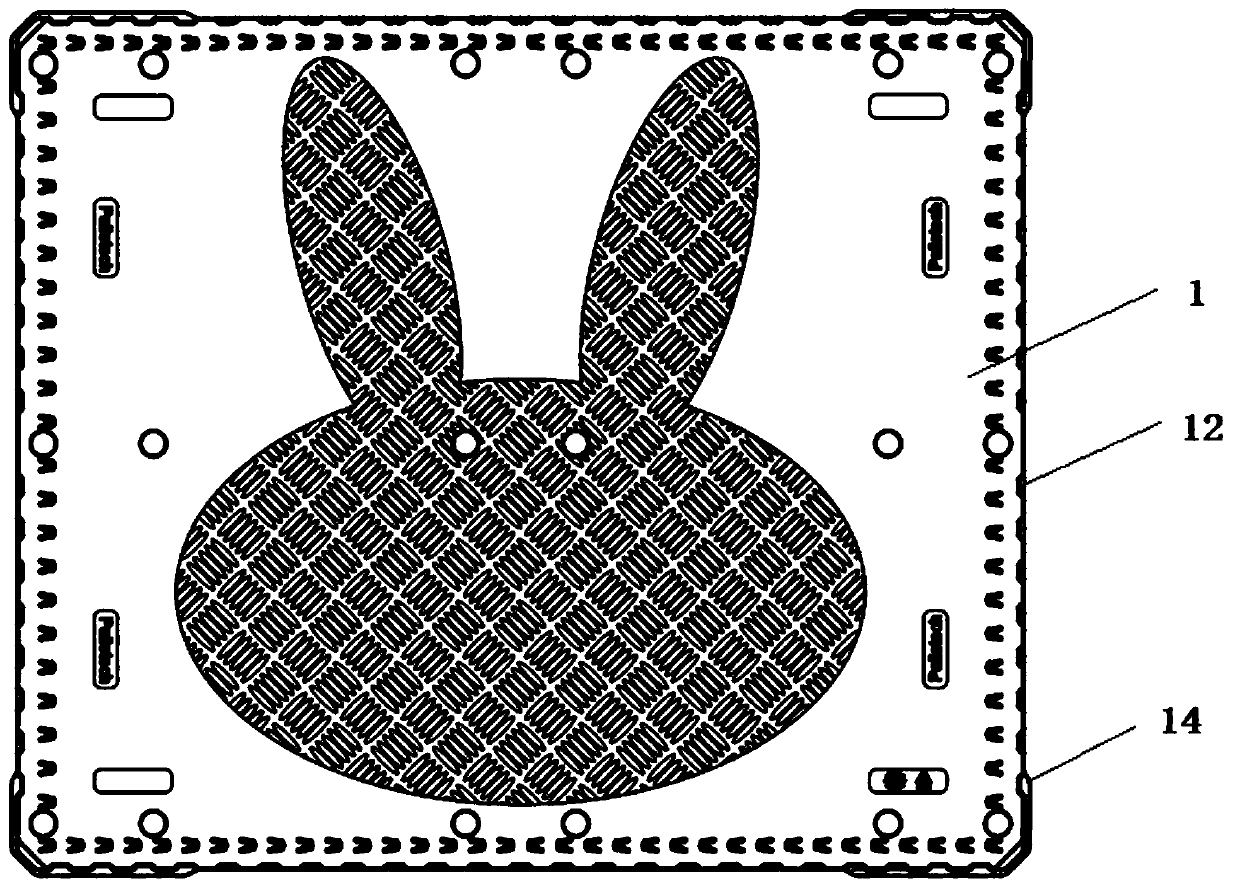

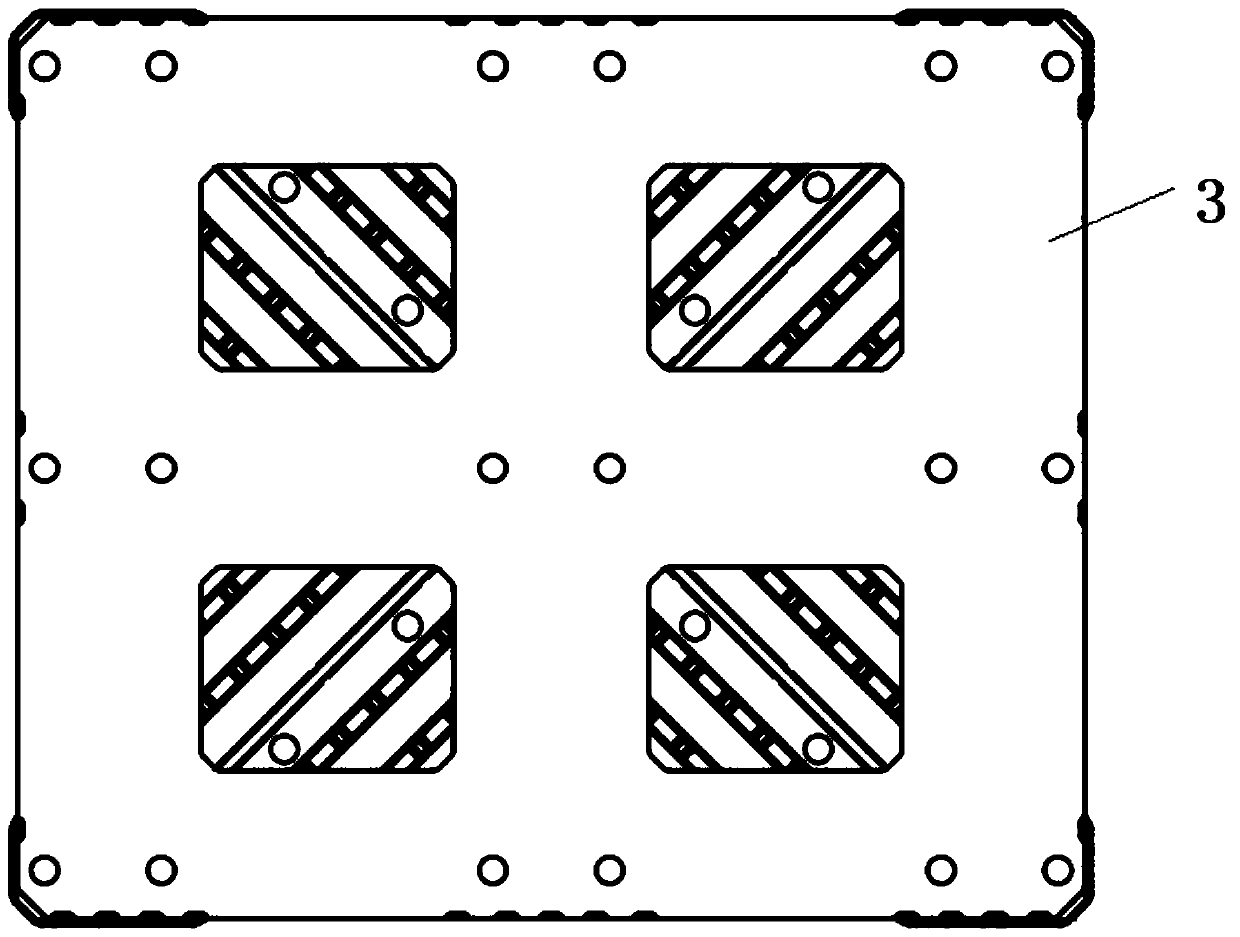

[0068] Specific embodiment 1: see Figure 1 to Figure 7 , a combined forklift pallet with high load-bearing strength injection molding and blow molding technology, including a plastic pallet body, the plastic pallet body includes a blow-molded polyethylene material top plate 1 and a polyethylene material injection-molded middle support column 2, the top plate 1 and The middle support column 2 is detachably connected; the top plate 1 is provided with an upper groove 11 embedded in the top of the middle support column 2; the top plate 1 is also provided with a roof reinforcement mounting groove 5 for embedding the reinforcement 4, and the roof reinforcement installation Groove 5 is partly opened at the upper groove 11; the middle support column 2 is provided with a well-shaped groove 22 for embedding the reinforcement 4; when the middle support column 2 is connected with the top plate 1, the reinforcement 4 is clamped and fixed on The space enclosed by the shape groove 22 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com