Universal joint structure of steel structure X-beam Y-shaped column

A technology for node structure and steel structure, which is applied in building construction, construction, etc., can solve problems such as self-heavy weight, steel structure truss installation and adverse effects of wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

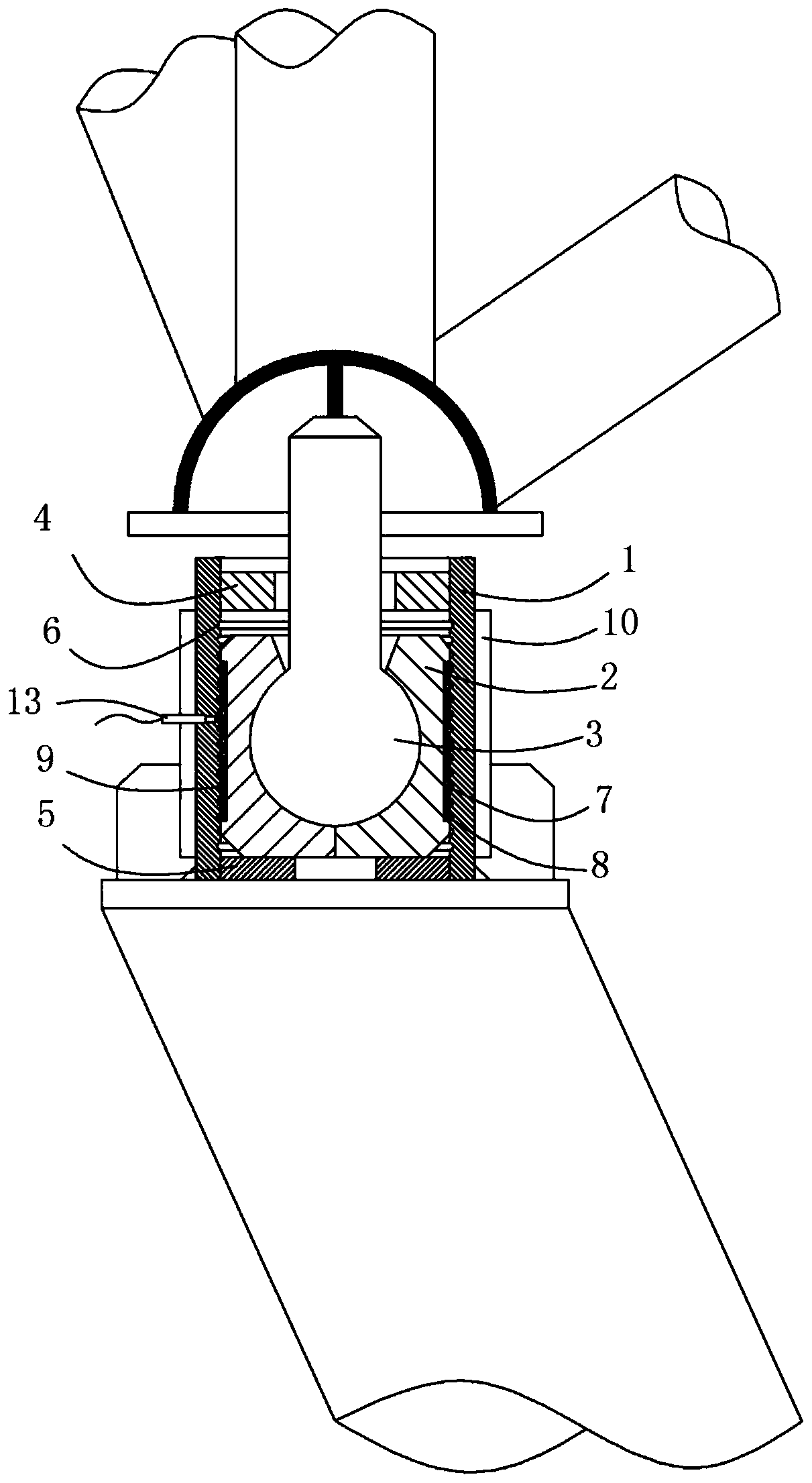

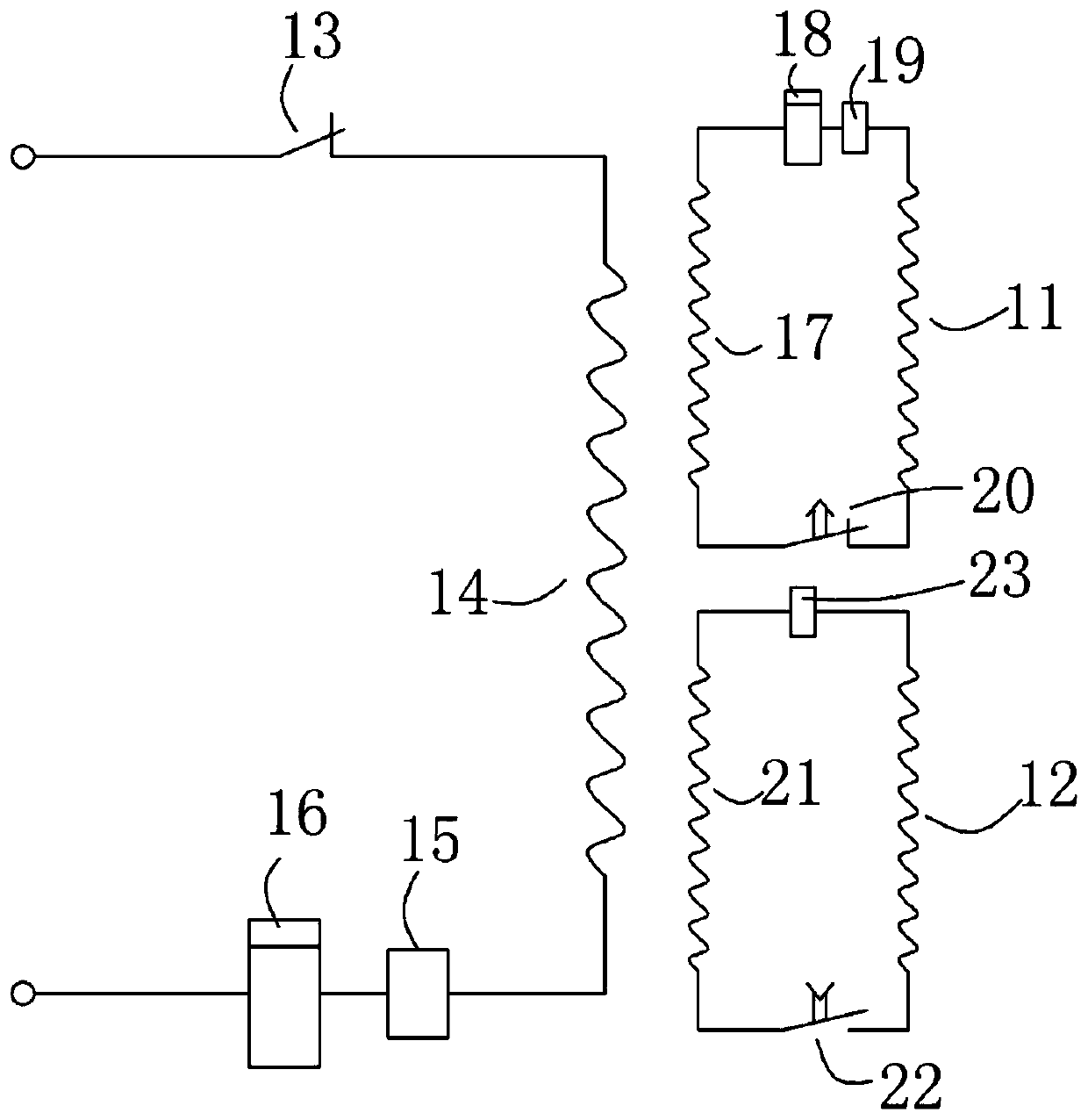

[0013] see figure 1 , shows a schematic structural view of the universal joint structure of the steel structure X-beam Y-shaped column of the present invention. The node structure is not located at the connection position between the steel structure and the ground foundation, but between the beams and columns of the truss, especially the multi-bar connection node shown in the figure, that is, the node structure is located between the main support beam column and the first branch beam column, the first branch beam column, and the second branch beam column. At the connection position of the beam-column of the second branch and the beam-column of the third branch, the connection form of universal ball joint commonly used in steel structure trusses is adopted. At the same time, combined with the automobile piston type up and down adjustment structure, it can ensure that the node structure realizes three-dimensional multi-directional stress unloading adjustment. The specific struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com