Double steel plate and concrete composite wall and construction method thereof

A construction method and concrete technology, applied to walls, building components, buildings, etc., can solve problems such as the inability to realize the connection between horizontal and vertical components, the connection between steel plate and concrete is not very reliable, and the discount of structural performance such as earthquake resistance and shear resistance , to achieve the effect of improving the construction period, saving materials, and improving the shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

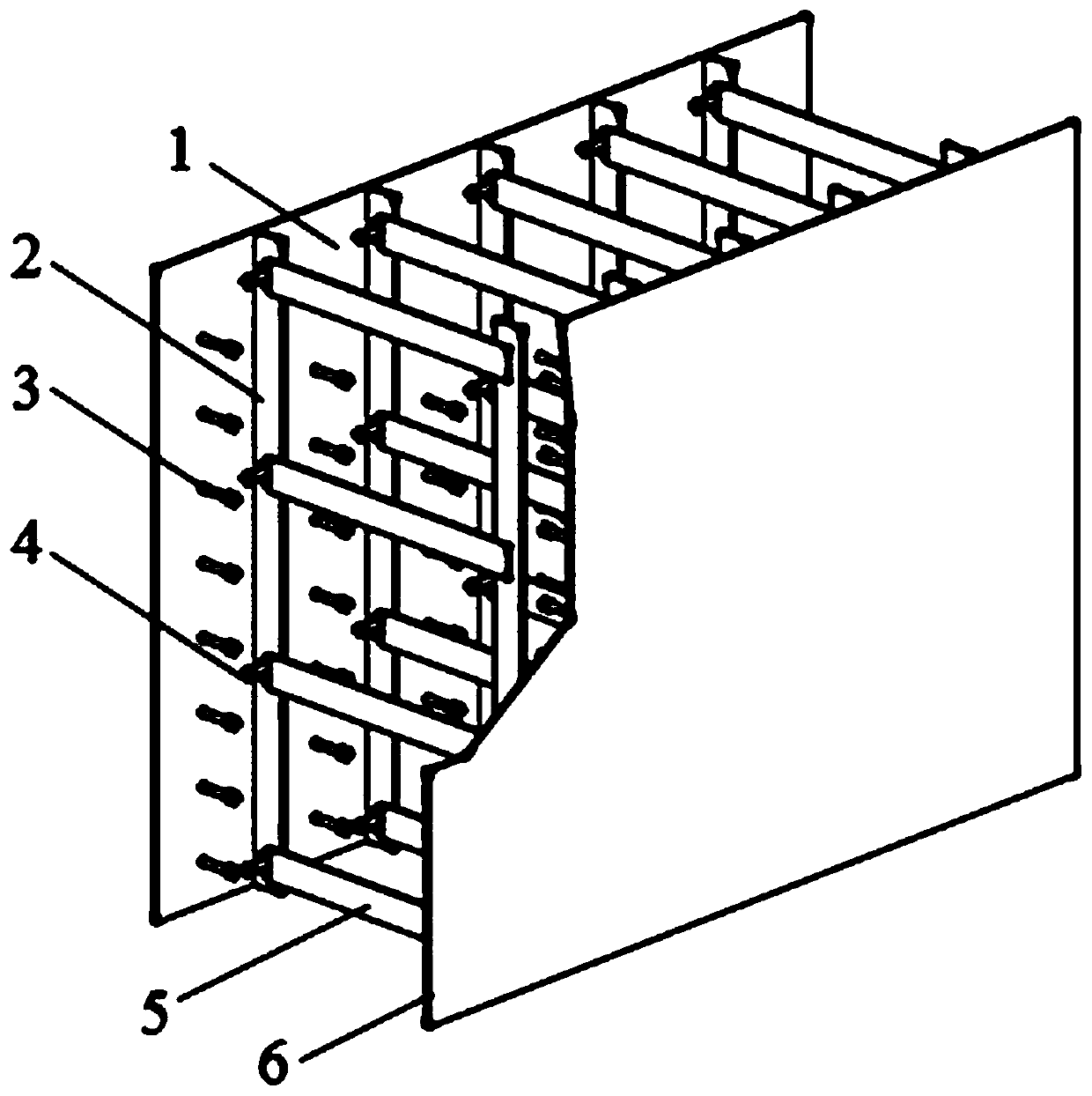

[0036] A double-steel-steel-concrete composite wall comprises a double-steel-slab layer and a concrete layer, the double-steel-slab layer comprises a first steel plate and a second steel plate of equal size, and the first steel plate and the second steel plate are used as concrete formwork, after pouring concrete , solidification is the concrete layer, the inner surfaces of the first steel plate and the second steel plate are welded with at least two transverse studs and longitudinal stiffeners, and the longitudinal stiffeners of the second steel plate are welded with steel The other end of the steel trim strip is a round hole, and the round hole of the steel trim strip is welded with a longitudinal peg corresponding to the stiffener of the first steel plate, and the peg can pass through the round hole so that the first steel plate It is fixedly connected with the second steel plate.

[0037] The positions of the stiffeners of the first steel plate and the second steel plate a...

Embodiment 2

[0041] The construction method of the above-mentioned double steel plate concrete composite wall comprises the following steps:

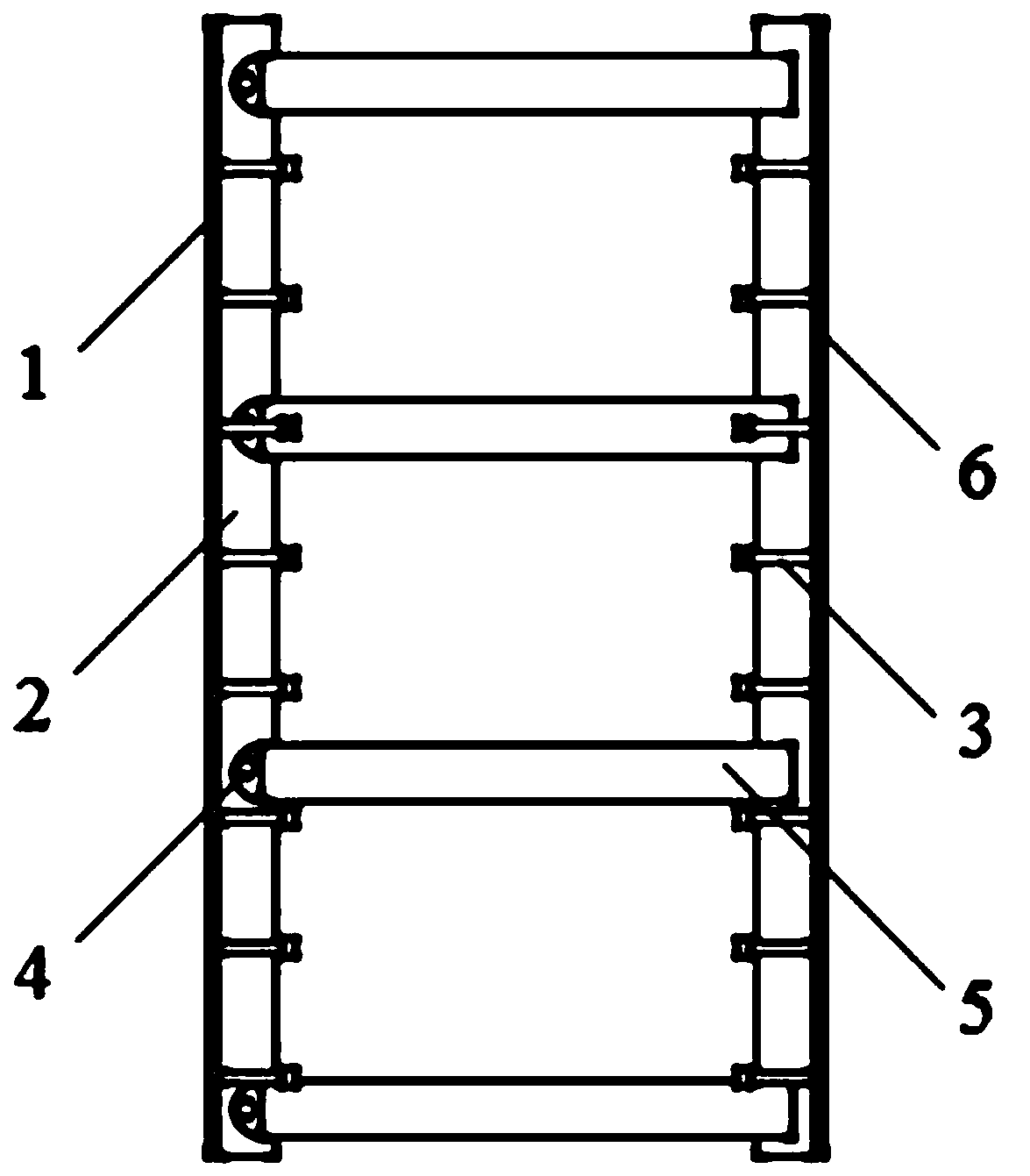

[0042]Step 1, weld stiffeners on the inner surfaces of the first steel plate and the second steel plate; Step 2, weld transverse studs on the inner surfaces of the first steel plate and the second steel plate to ensure that the welding quality is qualified; Step 3, according to the requirements of the building structure Determine the length of the steel trim strip, and open a round hole slightly larger than the diameter of the longitudinal stud at one end; step 4, weld the steel trim strip to the longitudinal stiffener of the second steel plate, and the longitudinal stiffener at the corresponding position of the first steel plate The ribs are welded with vertical studs perpendicular to the steel struts to ensure that the studs welded on the stiffeners during construction can catch the round holes of the steel struts; step 5, classify the labels of th...

Embodiment 3

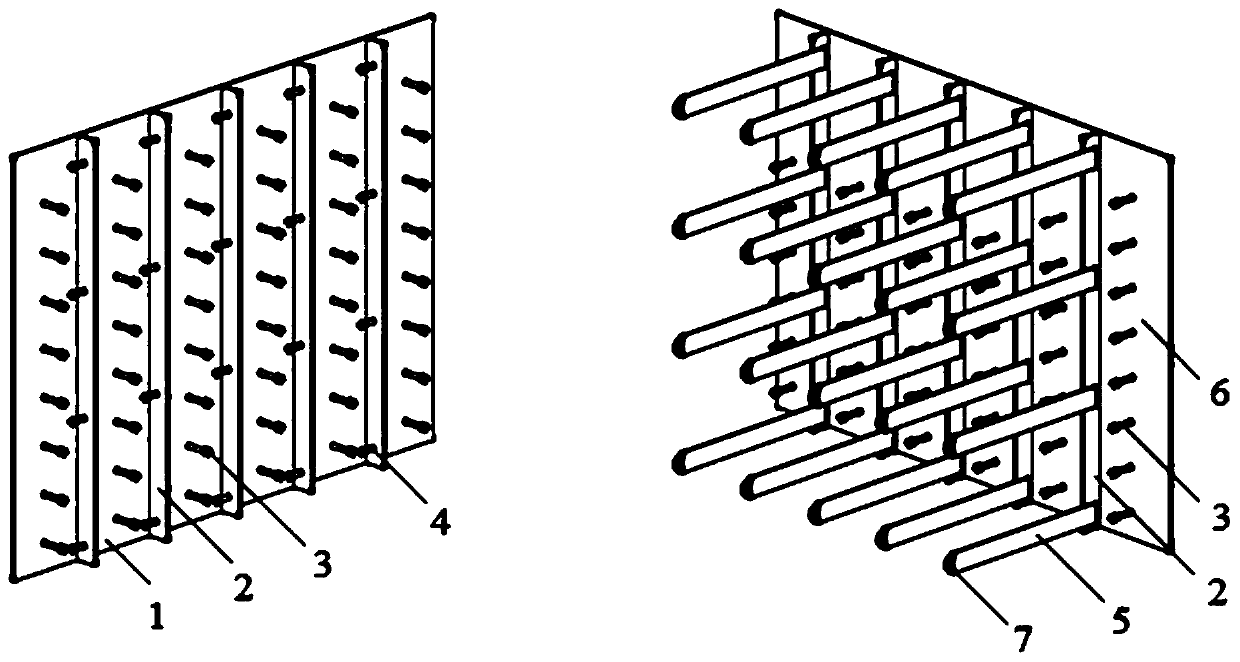

[0044] A double-steel plate concrete composite wall, except that the stiffening ribs of the first steel plate and the second steel plate are provided with longitudinal pegs, the connecting part is a snake-shaped tie bar, and the bending section of the snake-shaped tie bar Respectively correspond to the longitudinal pegs on the longitudinal stiffeners of the first steel plate and the second steel plate, and the rest are the same as in Embodiment 1.

[0045] The construction method of the double-steel plate concrete composite wall includes the following steps: 1. Welding transverse studs on the inner surfaces of the first steel plate and the second steel plate, and the welding equipment adopts low-current stud welding to ensure welding quality; 2. Stiffening in the longitudinal direction Weld longitudinal studs on one side of the ribs, and pay attention to the same welding spacing; 3. Weld the longitudinal stiffeners welded with longitudinal studs to the first steel plate and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com