Heliostat correction method based on mirror mark

A calibration method and heliostat technology, applied in the field of heliostat detection, can solve the problems of small number of targets, low calibration efficiency, unusability, etc., and achieve high calibration efficiency, wide recognition range, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

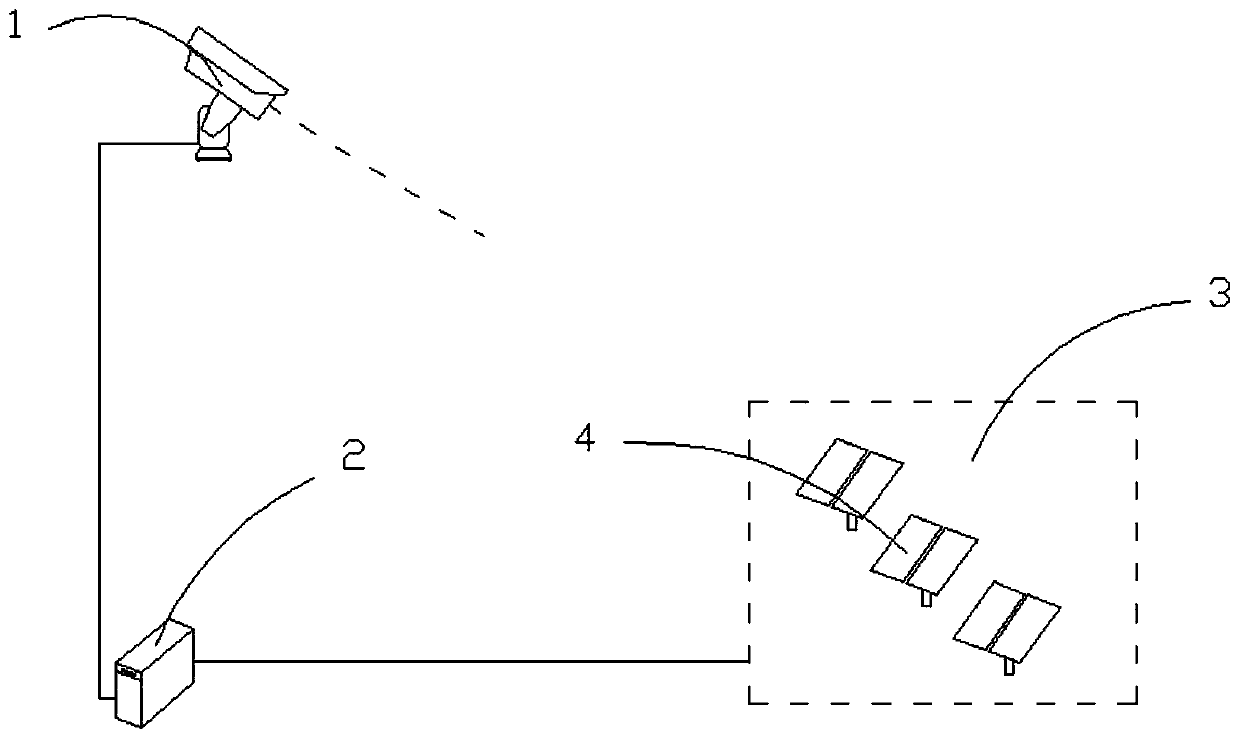

[0042] Please refer to figure 1 with figure 2 , A method for heliostat correction based on mirror mark, including the following steps:

[0043] S1. Set marking points at the four corners of the mirror surface of the heliostat 4.

[0044] The mark points are marked with a back shape, and the mirror field 3 is partitioned, and a pan-tilt camera 1 that collects the marked point images is set up on the heat absorption tower, so that the pan-tilt camera 1 can obtain all the partitions facing the pan-tilt camera 1 after rotating Heliostat 4, and survey and map the coordinate value, initial horizontal angle and initial azimuth angle of PTZ camera 1 in the lens field coordinate system.

[0045] As an embodiment, the circular mirror field 3 is divided into four regions: southeast, northeast, southwest, and northwest. Four pan / tilt cameras 1 are installed on the heat absorption tower. Each pan / tilt camera 1 rotates its horizontal angle and The azimuth angle can completely cover the heliosta...

Embodiment 2

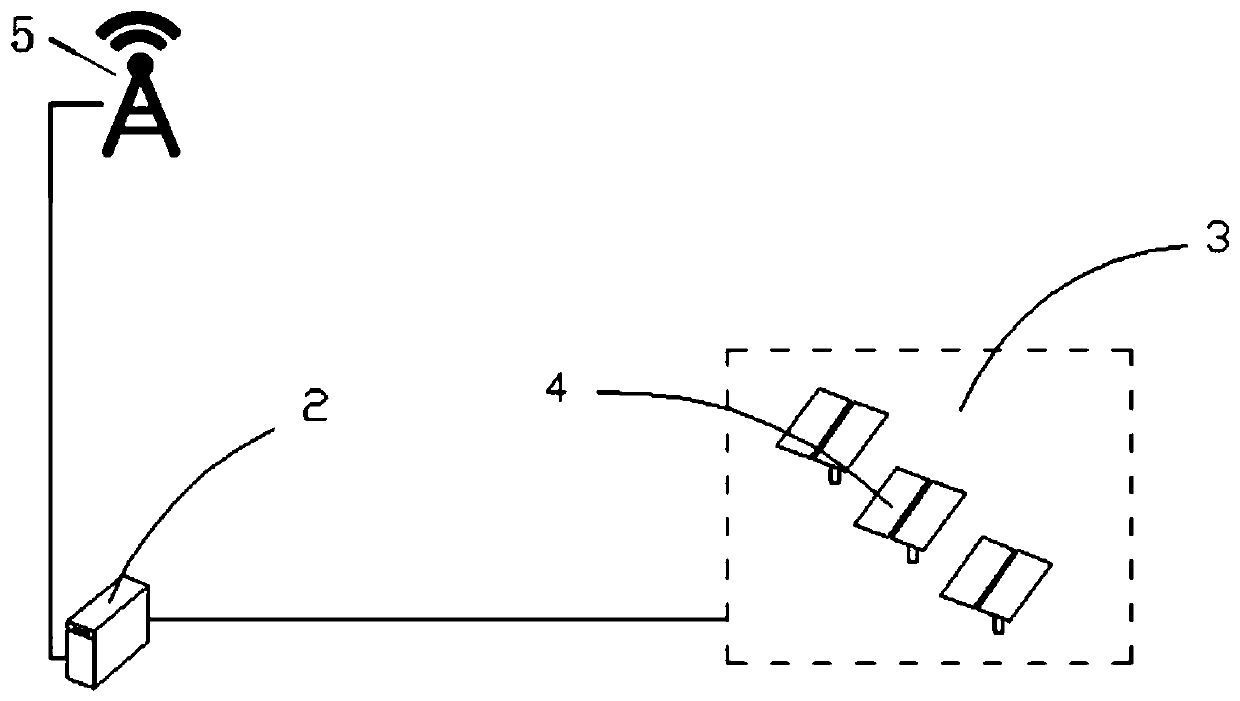

[0065] Please refer to image 3 with Figure 4 , A method for heliostat correction based on mirror mark, including the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com