Two-dimensional axisymmetric simulation model suitable for electromagnetic forming of pipe fitting with magnetic collector and modeling method

An electromagnetic forming and simulation model technology, applied in the field of metal material processing, can solve the problems of unguaranteed calculation accuracy, lack of axis symmetry, difficult mesh division, etc., and achieves fast calculation speed, reduced dimension, and computational complexity. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

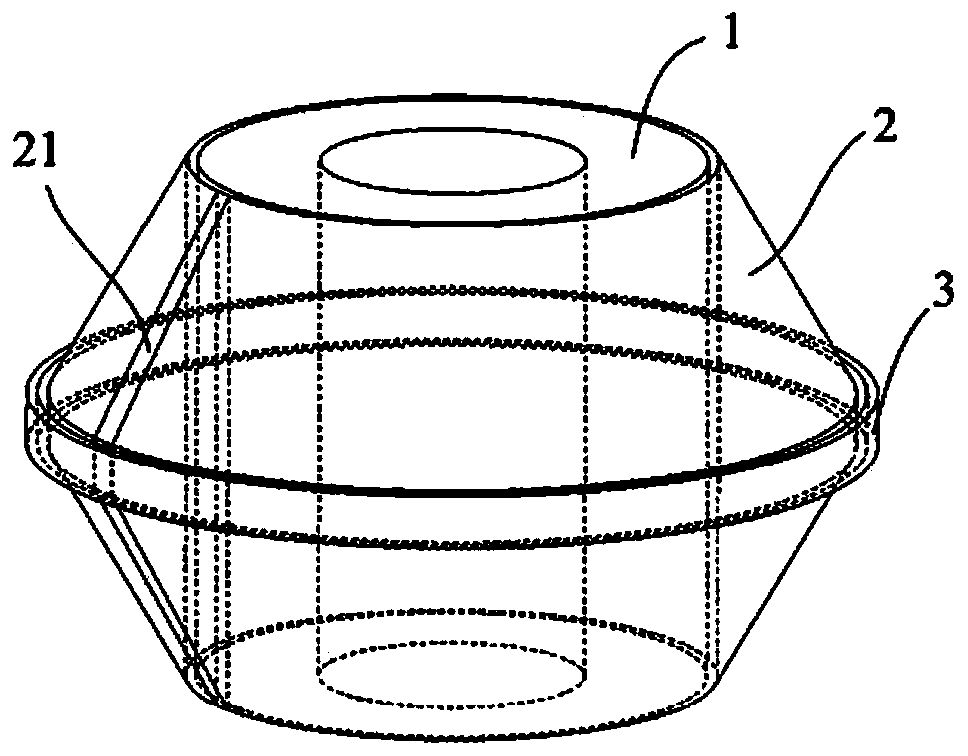

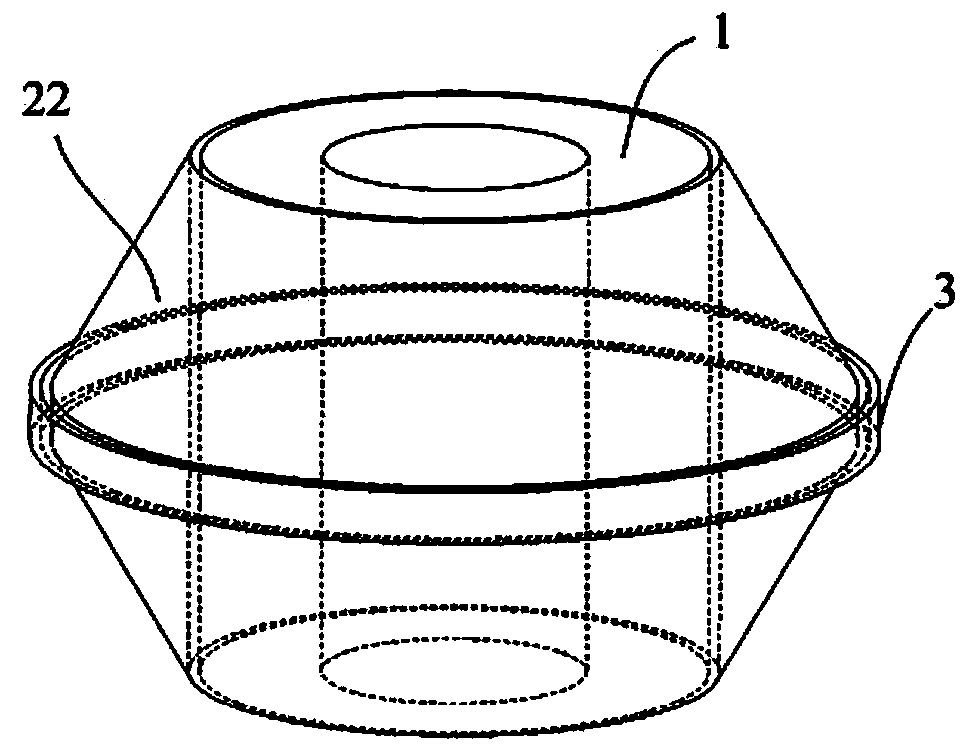

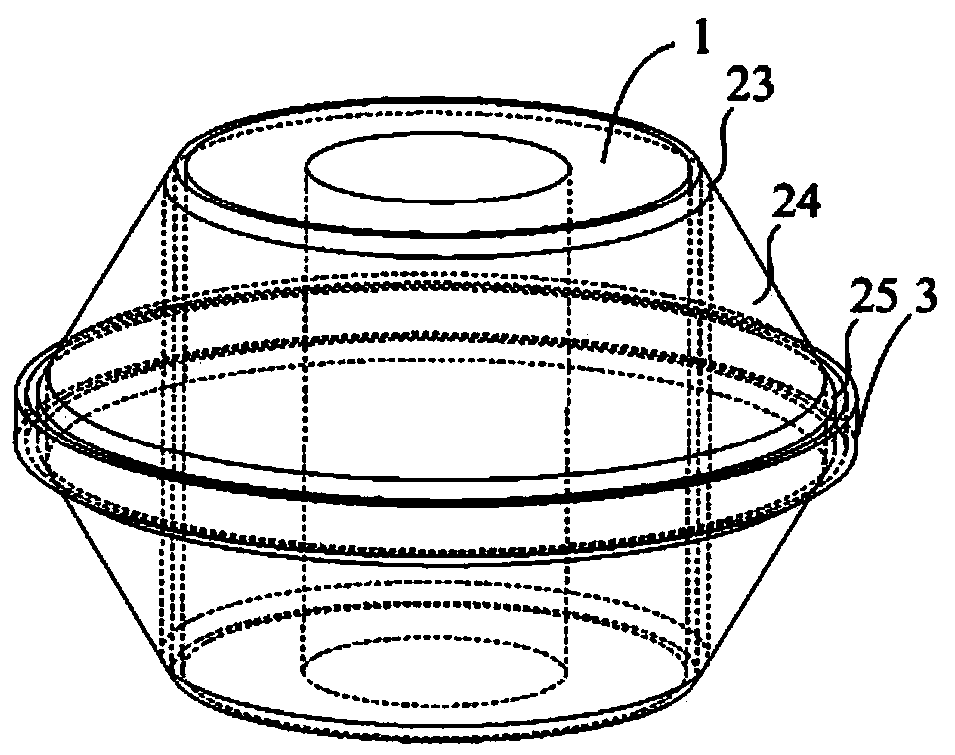

[0042] Figure 1(a) ~ Figure 1(d) Simplified process schematic diagram for a 2D axisymmetric simulation model suitable for electromagnetic forming of a tube with a magnet collector.

[0043] Figure 2(a) ~ Figure 2(d) A schematic diagram of the current distribution of the magnet collector.

[0044] image 3 It is a schematic flow chart of a two-dimensional axisymmetric simulation method suitable for electromagnetic forming of a tube with a magnet collector.

[0045]When the model is simplified, firstly, the original three-dimensional geometry of the electromagnetically formed pipe with the magnetizer shown in Figure 1(a) is used as a prototype to obtain the current distribution of the magnetizer in the original state, as shown in Figure 2(a).

[0046] according to image 3 Execute the first step S1: Replace the tiny gap of the magnet collector with the same conductor material as the magnet collector to make it a whole piece of axisymmetric conductor ring. At this time, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com