Method for preparing photovoltaic cell piece fine grid electrode by laser sintering metal wire

A technology of metal wires and photovoltaic cells, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems that the ability to collect current needs to be improved, and achieve the effects of good compactness, reduced shading area, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

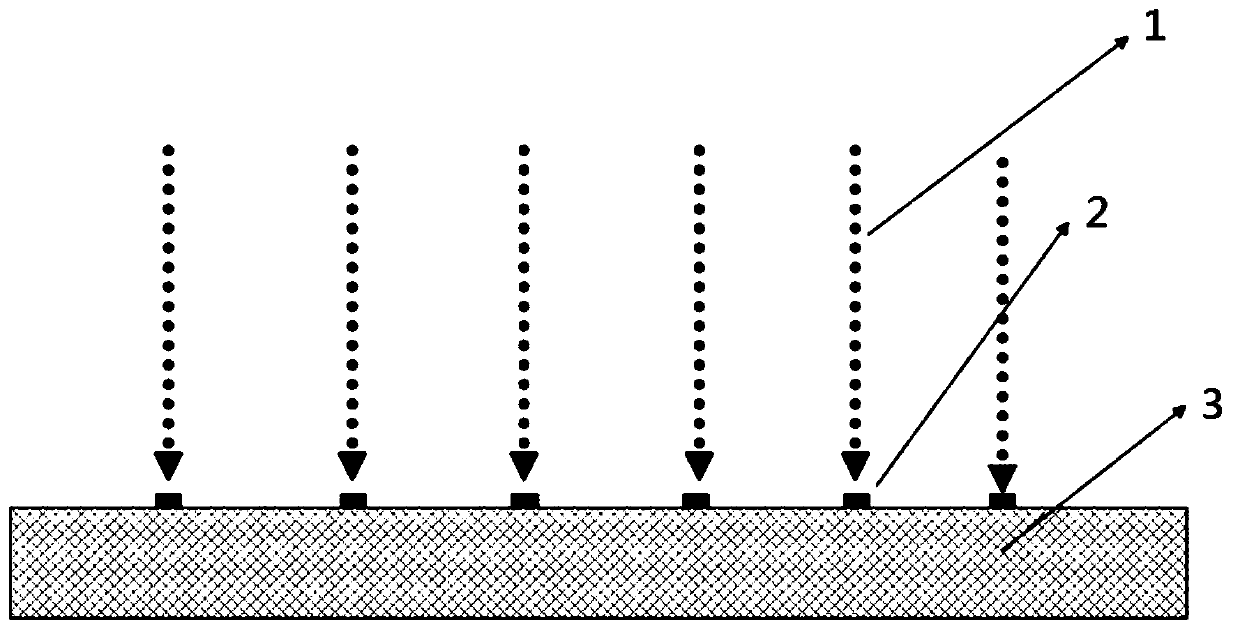

[0021] refer to figure 1 , a kind of laser sintering metal wire according to the present invention prepares the method for fine grid line electrode of photovoltaic cell sheet, comprises the following steps:

[0022] Step 1, prepare specific metal wires, such as pure silver wires with a diameter of 30 microns, and use a jig to make a row of metal wires, and the spacing between the metal wires is determined according to the specifications of the fine grid wires;

[0023] Step 2, paste the above-mentioned row of metal wires on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com