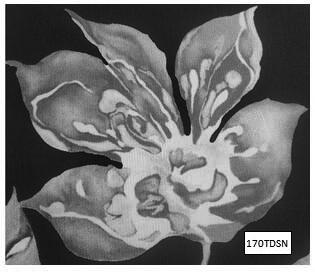

170TDSN printing rotary screen, preparation method and application thereof

A printing rotary screen and mesh technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of insufficient penetration effect, affecting printing level, low printing speed, etc., and achieve uniform and delicate color and excellent printing. Good quality and printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: A kind of preparation method of 170TDSN printing cylinder screen

[0056] Include the following steps:

[0057] (1) Production of tire mold

[0058] It includes the following steps: seamless steel pipe turning, nickel plating, copper plating, 170-mesh mesh rolling, chrome plating, embedding insulating glue, curing, and polishing.

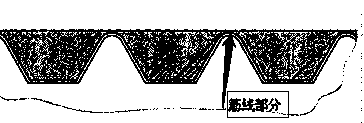

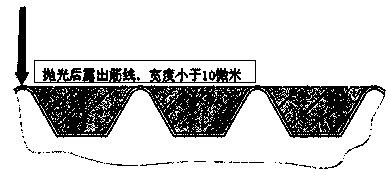

[0059]The polishing process is to ensure the narrow width of the ribs on the tire mold. A pneumatic polishing machine is used, and a polishing belt with a polishing pressure of 0.15~0.2Mpa and a particle size of 3µ is used for polishing to ensure that the ribs on the tire mold are even and wide. up to 8 µm.

[0060] (2) Primary plating

[0061] Use the 170-mesh tire mold with a rib width of 8µm as the cathode, and perform one electroplating in the primary electroplating tank, and use 140~150AH (140~150AH / m 2 ), and strictly control the plating thickness at 28 μm, so as to electroplate a single mesh with a porosity of 30.5% a...

Embodiment 2

[0083] Include the following steps:

[0084] (1) The production of the tire mold includes the following steps: seamless steel pipe processing, nickel plating, copper plating, 170 mesh mesh rolling, chrome plating, embedding insulating glue, curing, and polishing.

[0085] The polishing process is to ensure the narrow width of the ribs on the tire mold. A pneumatic polishing machine is used, and a polishing belt with a polishing pressure of 0.15~0.2Mpa and a particle size of 3µ is used for polishing to ensure that the ribs on the tire mold are even and wide. Equal to 10µm.

[0086] (2) Primary plating

[0087] Use the 170-mesh tire mold with the rib width equal to 10µm as the cathode, and perform one electroplating in the primary electroplating tank, and use 140~150AH (140~150AH / m2) per square meter of electroplating area 2 ), strictly control the plating thickness at 28 μm, and electroplate a single mesh with a porosity of 28% and a pore diameter of 79 μm. This electroplati...

Embodiment 3

[0109] Include the following steps:

[0110] (1) The production of the tire mold includes the following steps: seamless steel pipe processing, nickel plating, copper plating, 170 mesh mesh rolling, chrome plating, embedding insulating glue, curing, and polishing.

[0111] The polishing process is to ensure the narrow width of the ribs on the tire mold. A pneumatic polishing machine is used, and a polishing belt with a polishing pressure of 0.15~0.2Mpa and a particle size of 3µ is used for polishing to ensure that the ribs on the tire mold are even and wide. Equal to 9µm.

[0112] (2) Primary plating

[0113] Use the 170-mesh tire mold with a rib width equal to 9µm as the cathode, and perform one electroplating in the primary electroplating tank, and use 140~150AH (140~150AH / m 2 ), strictly control the plating thickness at 28μm, and electroplate a single mesh with a porosity of 29.5% and a pore diameter of 81μm. This electroplating process is an ordinary nickel electroplatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com