Manufacturing method of flexible circuit board capable of removing appearance deburring of base material

A technology of flexible circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, circuit bendable/stretchable components, printed circuits, etc., can solve problems affecting the appearance of flexible circuit boards, etc., to enhance strength and avoid burrs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

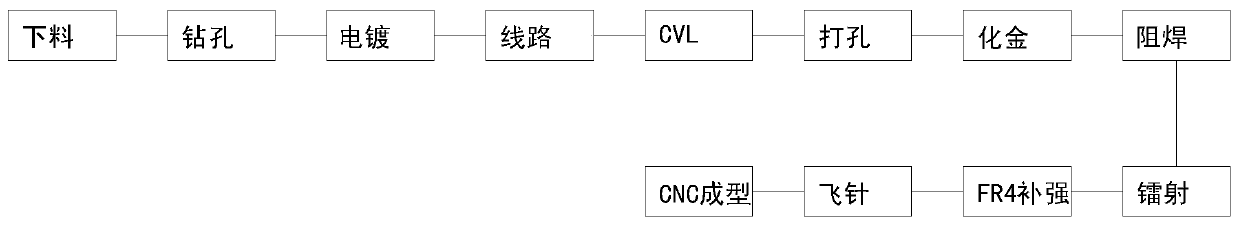

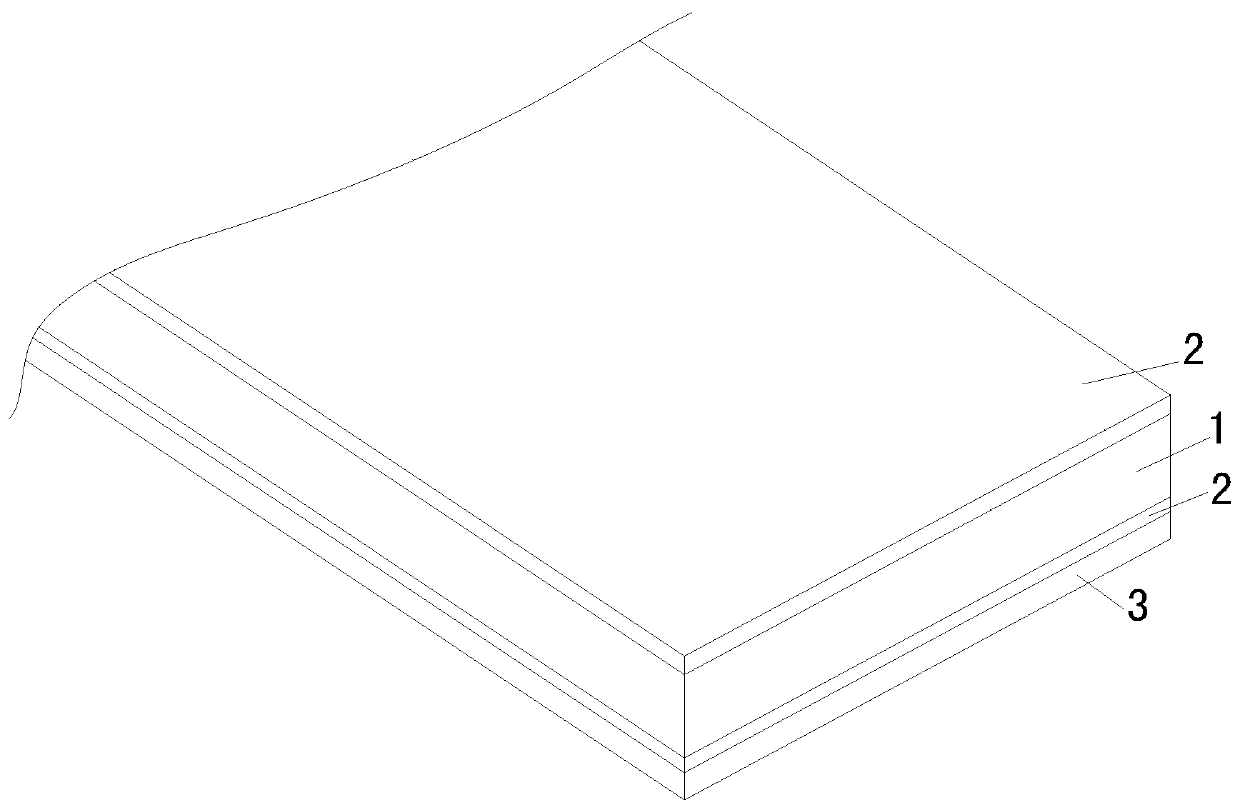

[0029] attached Figure 1-2 For the manufacturing method of the flexible circuit board that can remove the burr of substrate shape described in the present invention, comprise the following steps:

[0030] Substrate blanking: use the cutting machine to cut the corresponding size as required to form the substrate 1;

[0031] Substrate Drilling: Drill through holes (not shown) on substrate 1;

[0032] Electroplating: Copper is electroplated in the above-mentioned through holes;

[0033] Circuit production: according to the requirements, make circuits on the upper surface and the lower surface of the substrate 1 respectively, and make the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com