Milk and preparing method thereof

A milk and immunoglobulin technology, applied in other dairy products, dairy products, milking devices, etc., can solve the problems of loss of nutrients, hidden dangers of food safety, and high total microbial residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

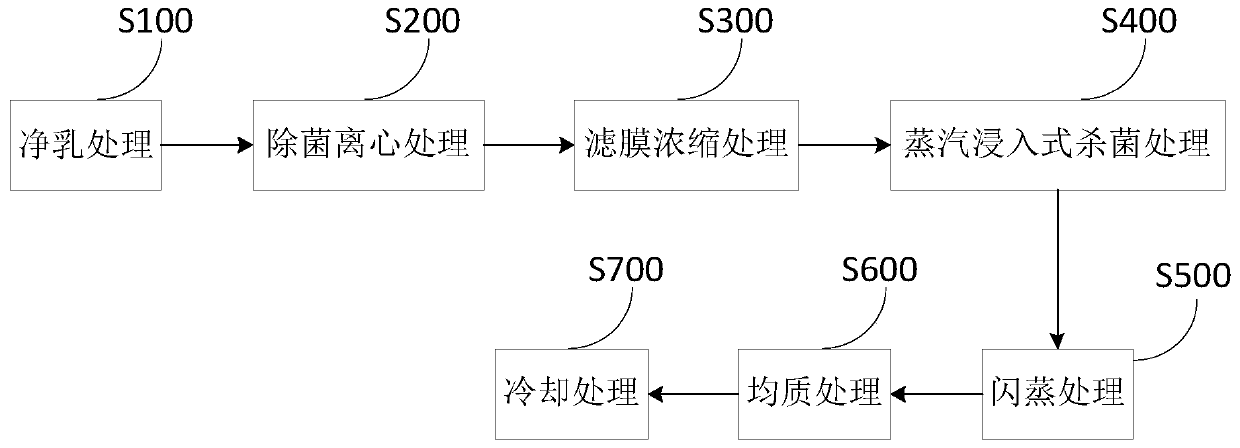

Method used

Image

Examples

Embodiment 1~6

[0064] In this example, milk was prepared as follows:

[0065] (1) Selection of fresh milk: select healthy cows in large-scale pasture breeding bases, and fresh milk squeezed from healthy cow udders with mechanized milking equipment.

[0066] (2) Acceptance: Check the protein, fat, non-fat milk solids, density and acidity contained in fresh milk. The acceptance criteria meet the national food safety standard GB19301. Qualified fresh milk is stored in cold chain at ①°C.

[0067] (3) Milk cleaning: pass the degassed milk through a filter, pass through a 100-120 mesh filter, remove dust and other impurities in the milk, and then pass the milk through a centrifugal static milk machine to control the temperature at ②°C to ③ Centrifuge at the speed of rpm to remove non-milk cells and other impurities in the milk.

[0068] (4) Centrifugal sterilization: The milk is subjected to centrifugal sterilization at a normal temperature of ⑤°C, and the microorganisms in the milk are physicall...

Embodiment 7

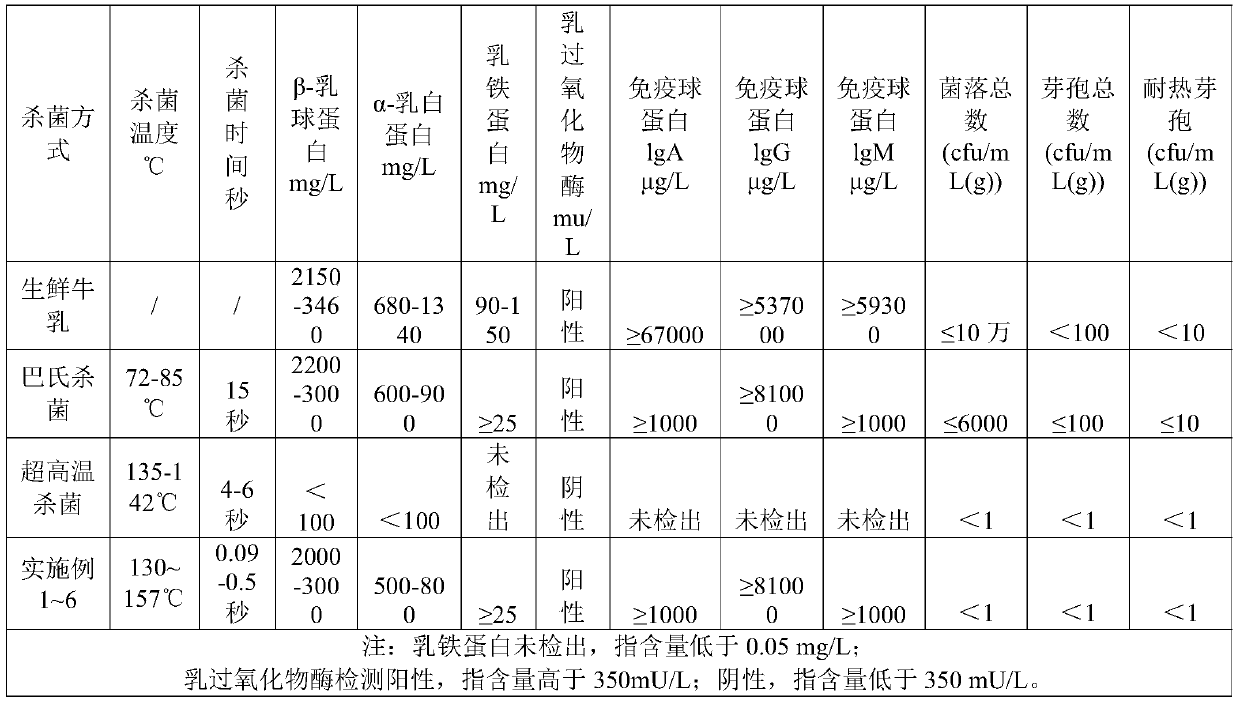

[0079] Prepare milk according to the method of Examples 1-6, the difference is that the sterilization conditions in step (7) are shown in the table below.

[0080] It can be seen that using the steam immersion sterilization method of the present invention, the sterilization temperature is controlled at 130-157° C., and the time is 0.09-0.5 seconds, which can effectively serve the purpose of sterilization, and microorganisms remain in the product, especially spores and heat-resistant spores The residues are all low, and compared with raw milk, the loss of nutrients is less, and the nutritional value of the product is high.

[0081] On the whole, the quality of milk obtained by the process of Example 4 is the best, and the raw milk composition is as follows: β-lactoglobulin: 3460 mg / L, α-lactalbumin: 1340 mg / L, lactoferrin: 110 mg / L, immune globulin Protein IgA: 67000 μg / L, Immunoglobulin IgG: 537000 μg / L, IgM: 59300 μg / L. The product composition is as follows: β-lactoglobulin:...

Embodiment 8

[0085]In this embodiment, the influence of different sterilization centrifugation temperatures on the removal effect of microorganisms is compared, as shown in the following table. It can be seen that the high-temperature sterilization and centrifugation method of the present invention can effectively improve the removal rate of microorganisms, especially spores and heat-resistant spores, greatly improve the quality level of products, have high safety, and extend the shelf life.

[0086] Table 3 Sterilization and centrifugation treatment methods

[0087] temperature setting Microbial removal rate Removal rate of spores and heat-resistant spores ≤7℃ 80-85% 80-85% 50-55℃ 90-93% ≥95%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com