System and method for treating asphalt smoke by using water washing method

A technology of water washing and dust, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of high operating cost, toxicity, and high viscosity, and achieve the effects of low operating cost, convenient installation and use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

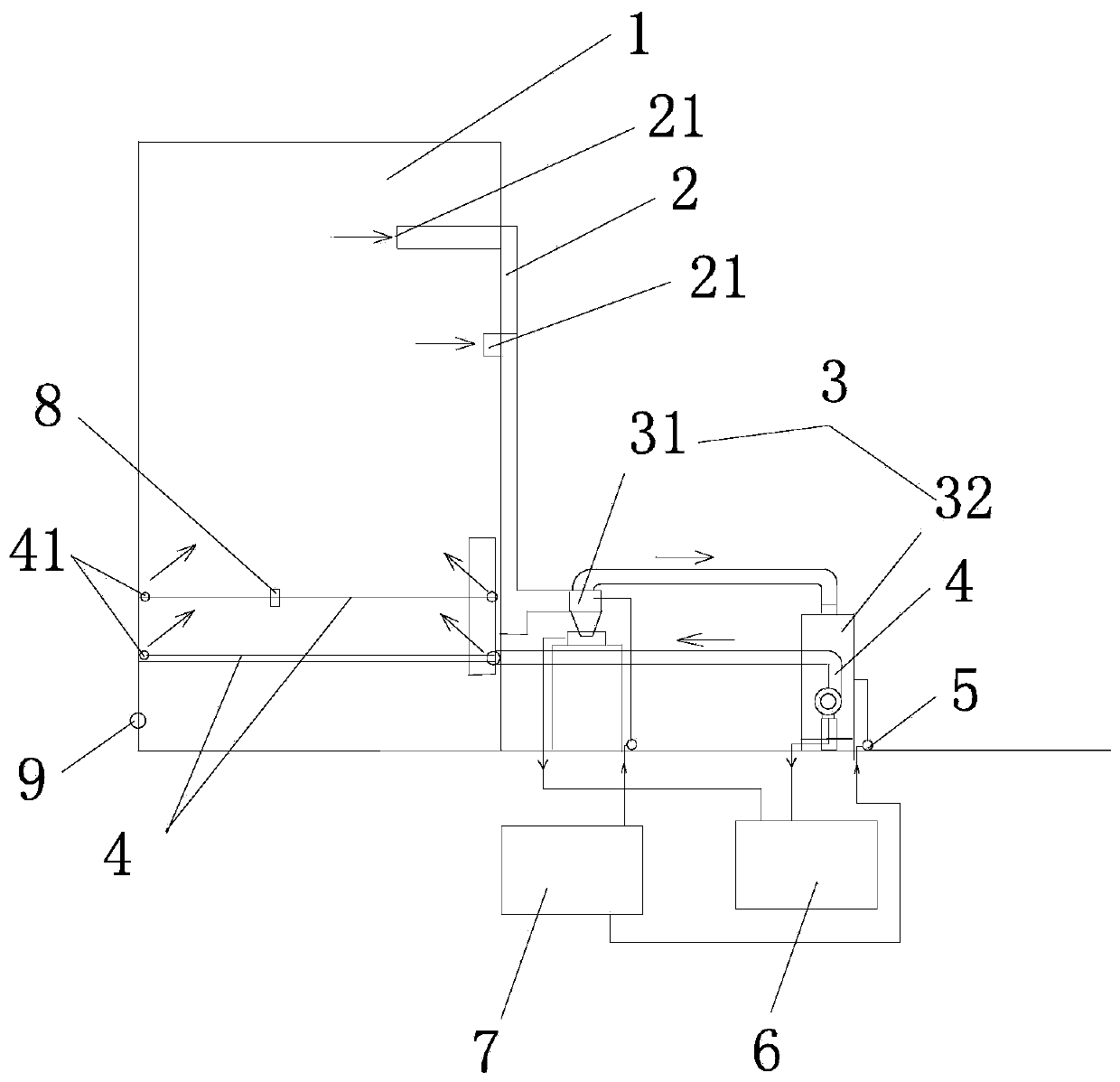

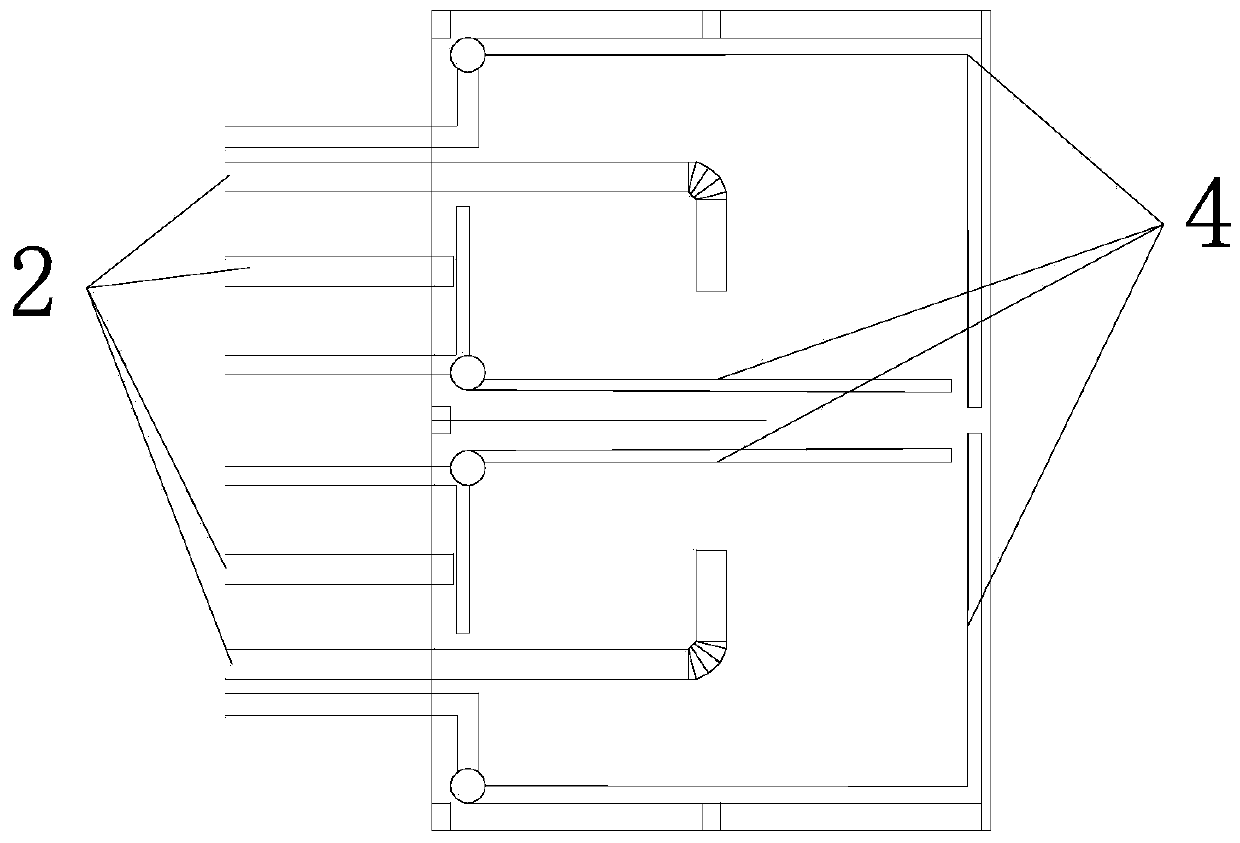

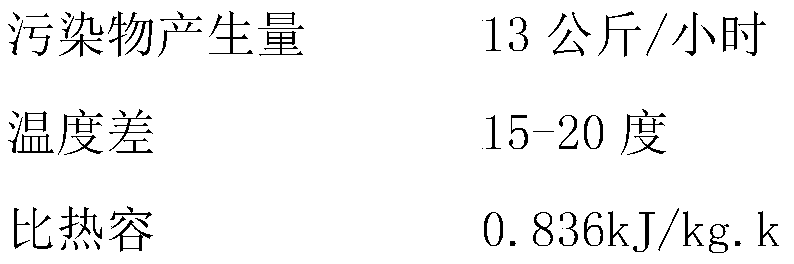

[0035] The present invention provides a water washing method for treating asphalt fume and dust, and a treatment method thereof. The method recycles air containing asphalt fume. First, the contaminated air is cleaned with 2-level water mist, and then returned after dust removal and deodorization. Use to avoid direct emission of polluted air. Then the purified smoke and dust are blown upward from the lower floor of the workshop when they are returned to use, so that the falling smoke and dust will drift in a directional direction until they are sucked away. Effective management of the smoke and dust is carried out so that the smoke and dust can be absorbed as much as possible. The recycled air can achieve zero emission of asphalt smoke.

[0036] See figure 1 The basic structure of the system is: a water washing method for treating asphalt smoke and dust, which is applied to the forming of anode carbon blocks. The system includes a forming workshop 1 with a height of more than 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com