Bottle cap having storage function and used for pesticide bottle

A technology for bottle storage and caps, which is applied in the field of pesticide bottle storage and caps, and can solve problems such as user poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

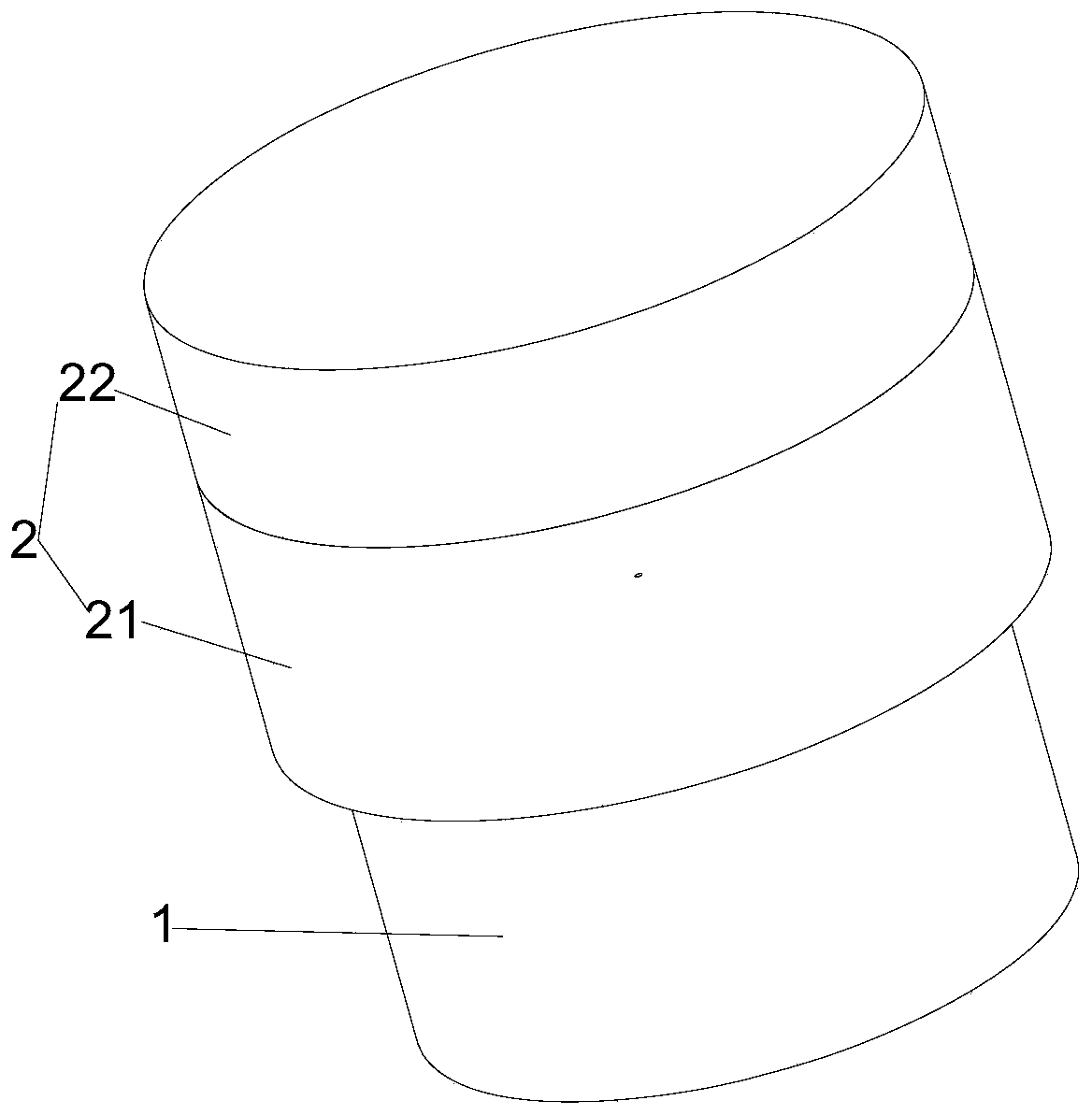

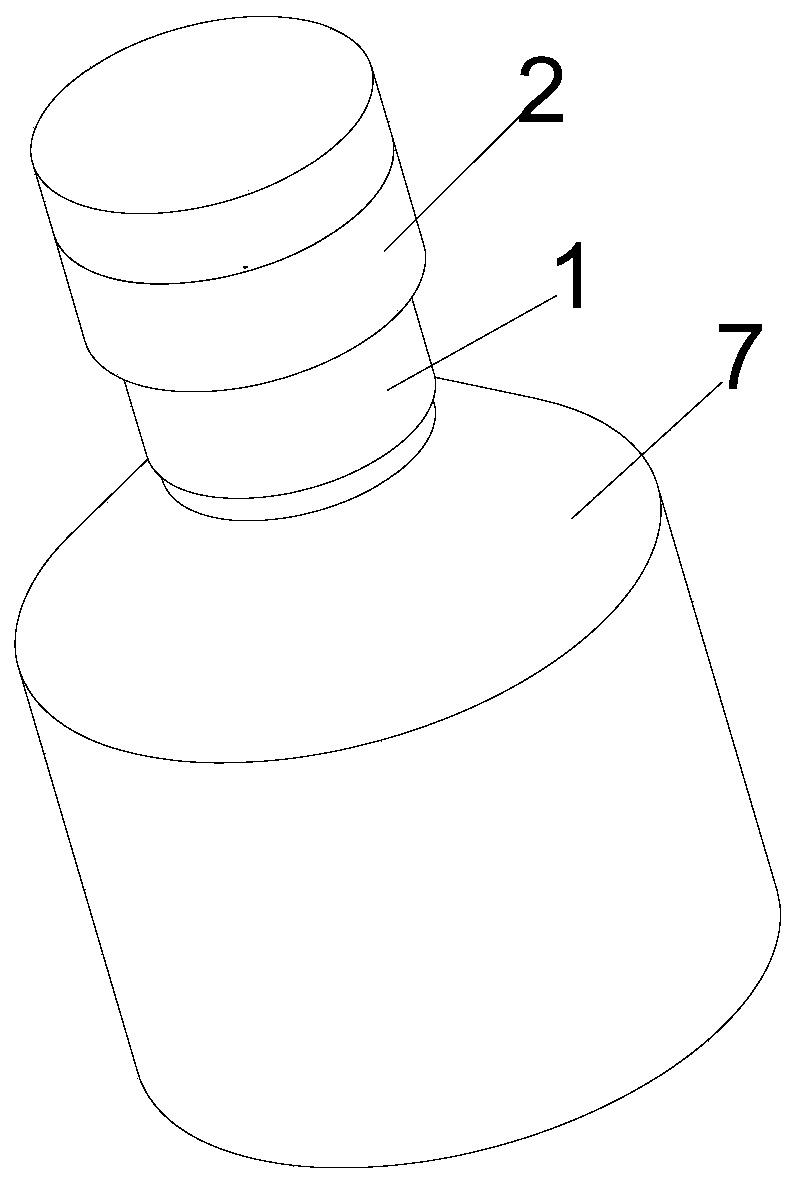

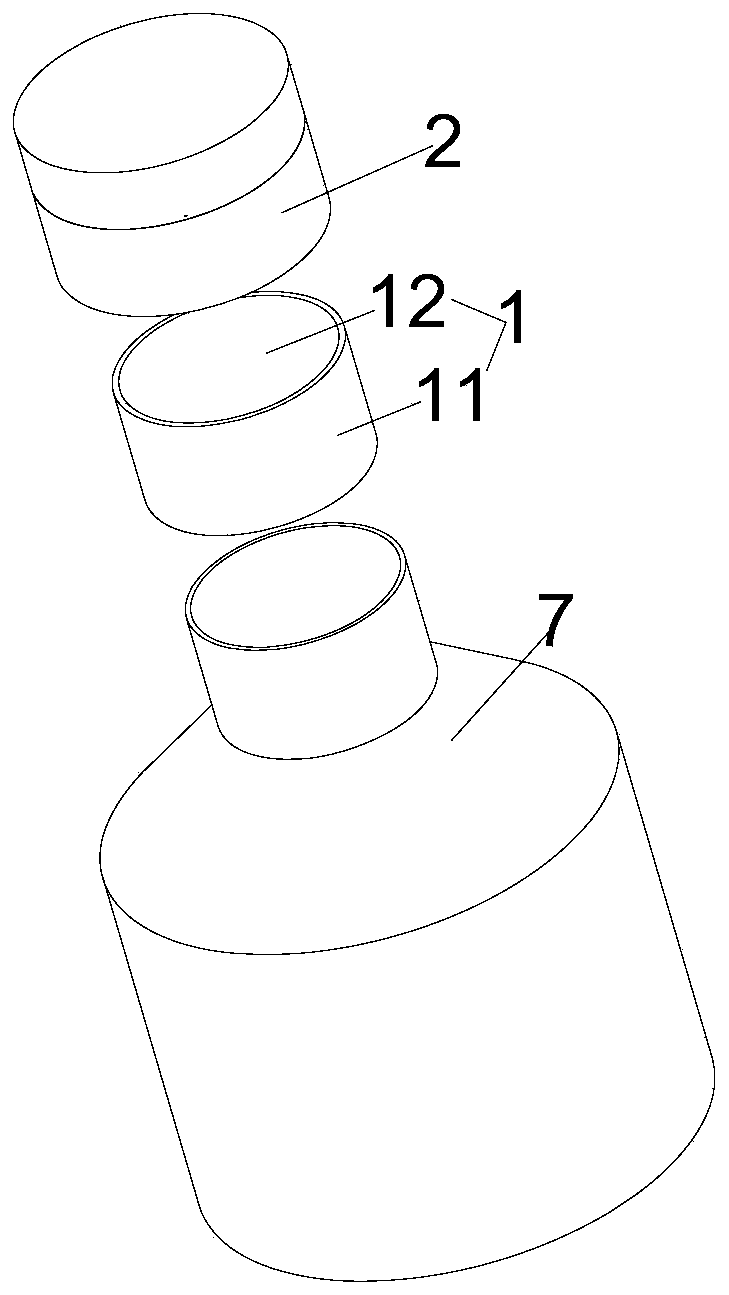

[0046]This embodiment provides a pesticide bottle storage cap, including a connecting cap 1 and a storage cap 2, the connecting cap 1 includes a first straight pipe 11 and tinfoil 12, the inner wall of the first straight pipe 11 is provided with internal threads, For screwing on the bottleneck of the pesticide bottle 7, the outer wall of the first straight pipe 11 is provided with an external thread, and the above-mentioned tinfoil 12 is bonded to the top of the first straight pipe 11 so that the first straight pipe 11 Due to the effect of tinfoil 12, the pesticide bottle 7 is completely in a sealed state.

[0047] Above-mentioned storage cover 2 comprises second straight pipe 21 and loam cake 22, and the middle part of above-mentioned second straight pipe 21 is provided with blocking plate 23, and this blocking plate 23 can block second straight pipe 21, and this blocking plate 23 passes heat It is connected to the inner wall of the second straight pipe 21 in a melting manner...

Embodiment 2

[0057] This embodiment is an improved implementation of Embodiment 1. In this embodiment, a round hole 241 is provided at the center of the upper surface of the arc plate 24. The round hole 241 is a structural member made of hard rubber. The mode of melting is affixed to the upper surface of the arc plate 24, and the central axis of the circular hole 241 passes through the center of the arc plate 24 vertically.

[0058] A cylinder 233 is arranged at the top wall center position of the above-mentioned circular interlayer 232, and the cylinder 233 is adapted to the above-mentioned circular hole 241, and the circular hole 241 is inserted in the cylinder 233, so that, between the circular hole 241 hole wall and the cylinder 233 outer wall The interference effect of the superior arc plate 24 can only rotate around the cylinder 241 without deviation, which can make the rotation of the superior arc plate 24 in the circular interlayer 232 more smooth, and enhance the stability of the p...

Embodiment 3

[0061] This embodiment is further improved on the basis of Embodiment 1. In this embodiment, a puncture needle 28 for piercing the tin foil paper 12 is also provided at the bottom of the above-mentioned funnel 27, the needle point of the puncture needle 28 is facing downward, and The needle tip of the puncture needle 28 is also located in the second straight tube 21 and will not protrude from the second straight tube 21 , so as to prevent the user from being stabbed by the needle tip of the puncture needle 28 . The puncture needle 28 is fixedly mounted on the bottom end of the funnel 27 by bonding.

[0062] In order to further prevent the user from being stabbed by the needle tip of the puncture needle 28, in the present embodiment, a plastic sheet is also bonded to the lower end of the second straight tube 21, and the plastic sheet can seal the puncture needle 28 in the second straight tube. In the tube 21, when it needs to be used, the user can tear off the plastic sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com