Reinforcement cage leveling method based on reinforcement cage leveling equipment

A steel cage and horizontal hanging technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of affecting the strength of the formed column, the small number of hanging points, and the influence of lowering the steel cage, so as to facilitate popularization and use and reduce complexity degree, good effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

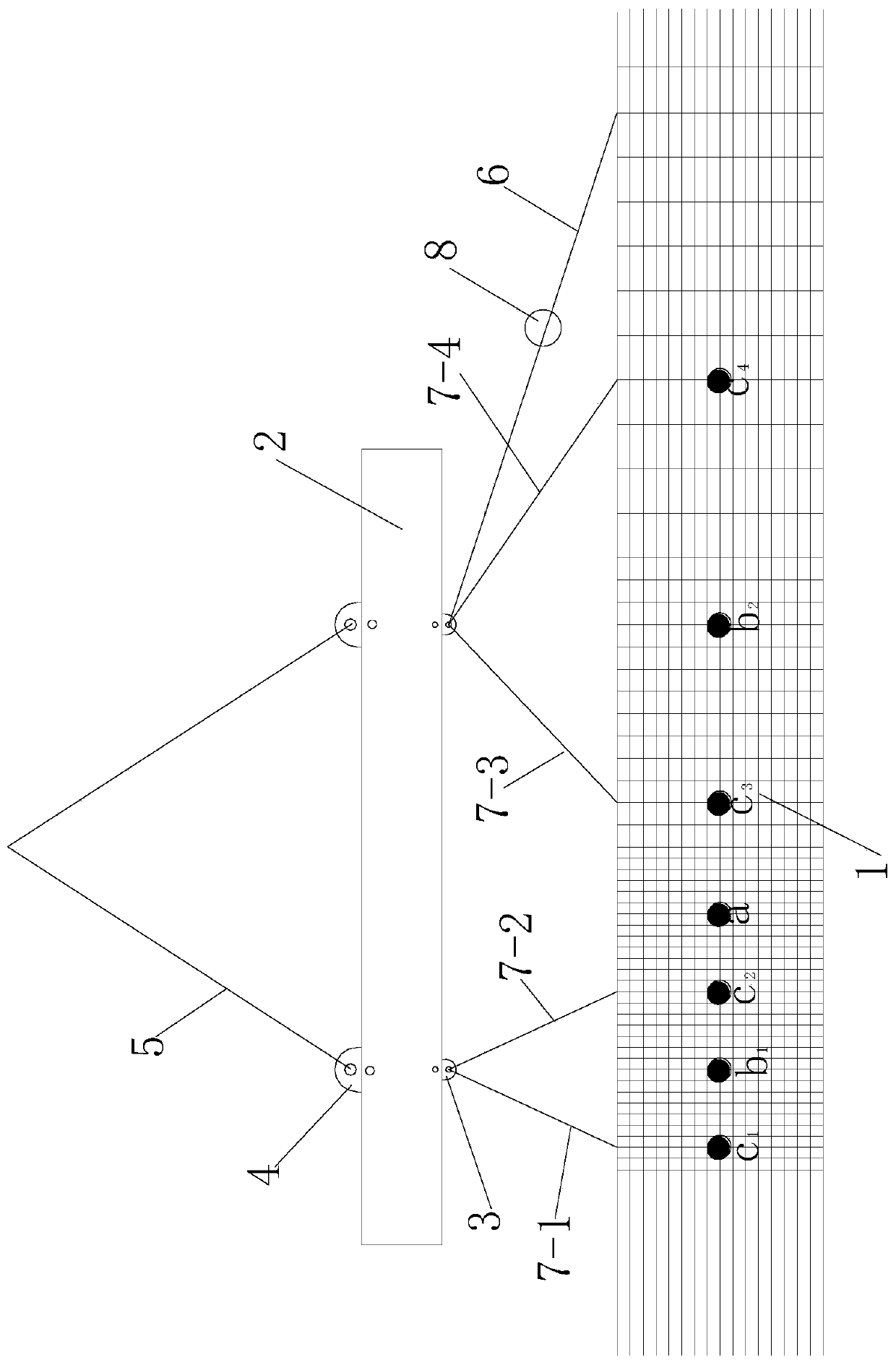

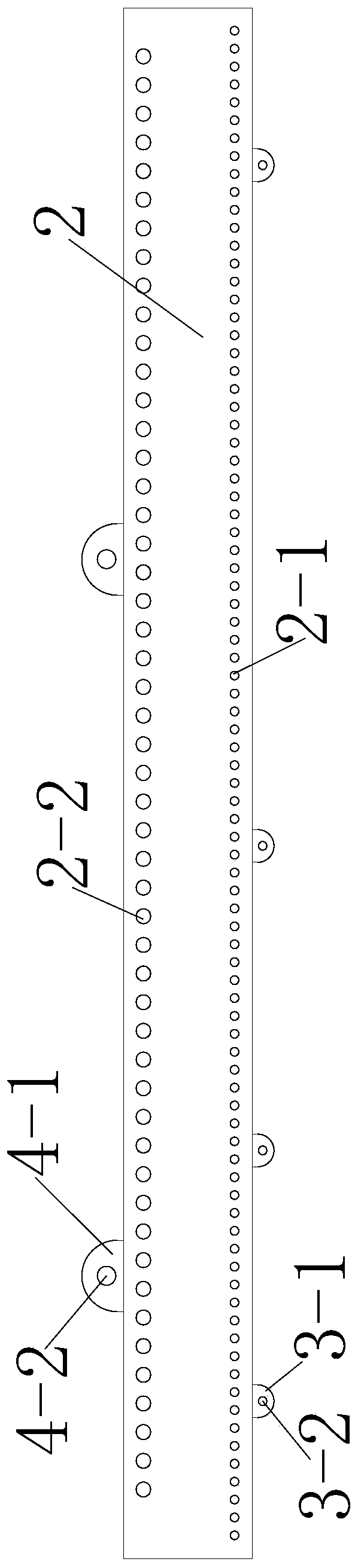

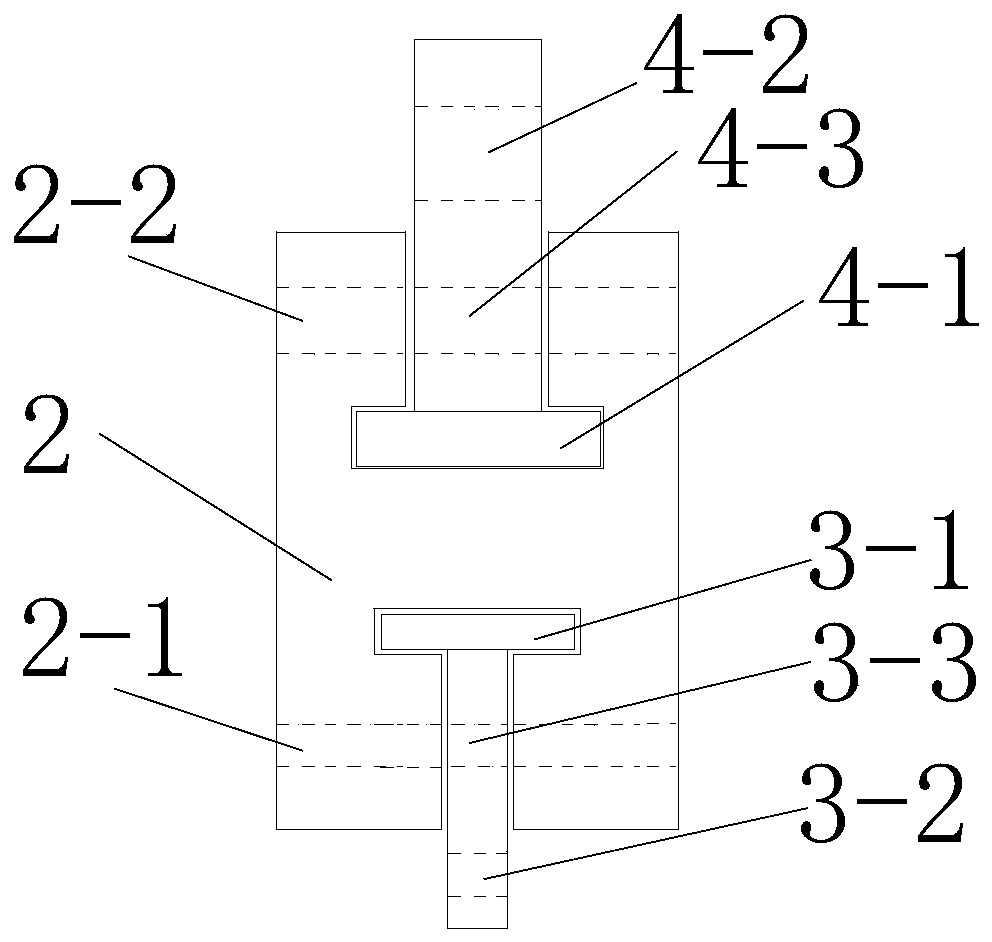

[0055] Such as Figure 1 to Figure 10 ,as well as Figure 12 As shown, the present invention is based on a steel cage level hoisting method based on steel cage level hoisting equipment. The main lifting lug 4 and a plurality of reinforcement cage connection lugs 3 installed on the lower side of the horizontal suspension beam 2 along the length direction of the horizontal suspension beam 2 and used for horizontal suspension of the reinforcement cage 1, the number of reinforcement cage connection suspension lugs 3 is 2 n wherein, n is a positive integer not less than 1; the top of the flat hanging beam 2 is provided with an inverted T-shaped chute, the bottom of the flat hanging beam 2 is provided with a T-shaped chute, and the bottom of the flat hanging beam 2 is provided with a A plurality of first flat hanging beam through holes 2-1 for positioning the reinforcement cage connecting lugs 3, the first flat hanging beam through holes 2-1 communicate with the vertical section of...

Embodiment 2

[0084] Such as Figure 11 As shown, the difference between this embodiment and embodiment 1 is that n is 2, and the third-level reinforcement cage segment is continued to be divided on the basis of the four third-level reinforcement cage segments in embodiment 1, and eight fourth-level reinforcement cage segments are obtained. Level reinforcement cage segment, and obtain the center of gravity corresponding to the eight fourth-level reinforcement cage segments, and the corresponding gravity centers of the eight fourth-level reinforcement cage segments are the four-level center of gravity of the reinforcement cage d 1 , the center of gravity of the fourth stage of the reinforcement cage d 2 , Reinforcement cage level four Center of gravity d 3 , the center of gravity of the fourth stage of the reinforcement cage d 4 , the center of gravity of the fourth stage of the reinforcement cage d 5 , the center of gravity of the fourth stage of the reinforcement cage d 6 , four-level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com