Retainer-free surface micro-texture self-lubricating cylindrical roller bearing with isolator

A technology of cylindrical roller bearings and cylindrical rollers, which is applied to bearings, bearing components, shafts and bearings, etc., and can solve problems such as limiting the limit speed and large friction of cylindrical roller bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

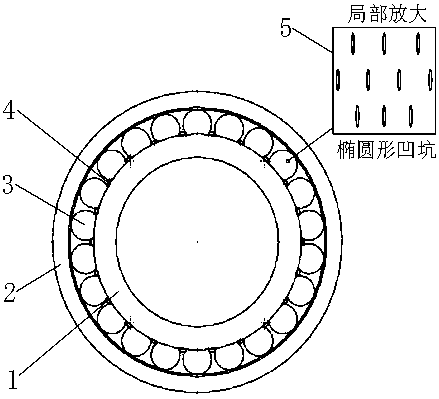

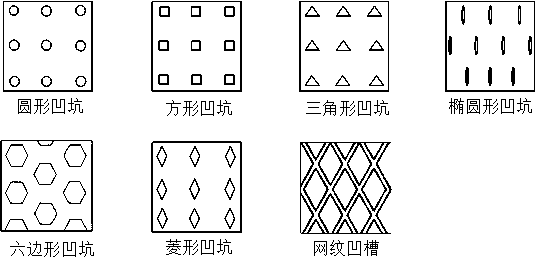

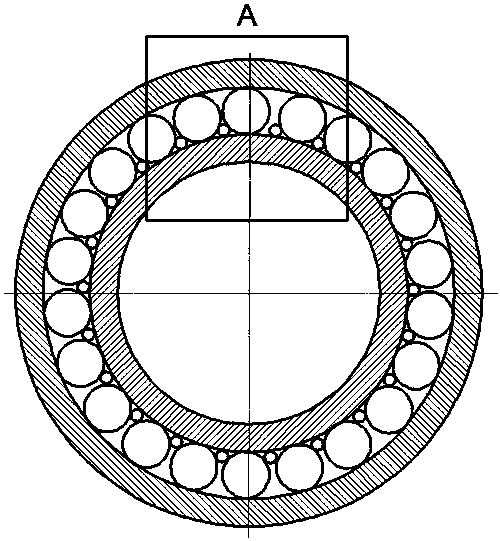

[0017] Such as figure 1 As shown, a surface micro-textured self-lubricating cylindrical roller bearing with an isolator and no cage is characterized in that it includes an inner ring 1, an outer ring 2, a cylindrical roller 3, an isolator 4 and a surface micro-texture 5 There are five parts in total. There are double ribs on the outer side of the inner ring 1, and the inner raceway groove formed thereby restricts the axial movement of the cylindrical roller 3 and the isolation body 4. The spacer 4 is a slender cylinder. The specific quantity and diameter should be determined according to the specific quantity and size of the cylindrical rollers. The determination principle is that when the bearing is placed vertically, due to the action of gravity, the uppermost two adjacent cylindrical rollers will The distance between the rollers 3 is the largest, so that the diameter of the spacer 4 is slightly larger than this space, so as to ensure that the spacer 4 cannot fly away from b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com