Nuclear power station three-dimensional model repair control unit, system and method

A technology of three-dimensional model and control unit, applied in information technology support system, electrical digital data processing, image data processing, etc., can solve problems such as hidden dangers, achieve the effect of improving work efficiency, improving repair accuracy, and reducing on-site workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

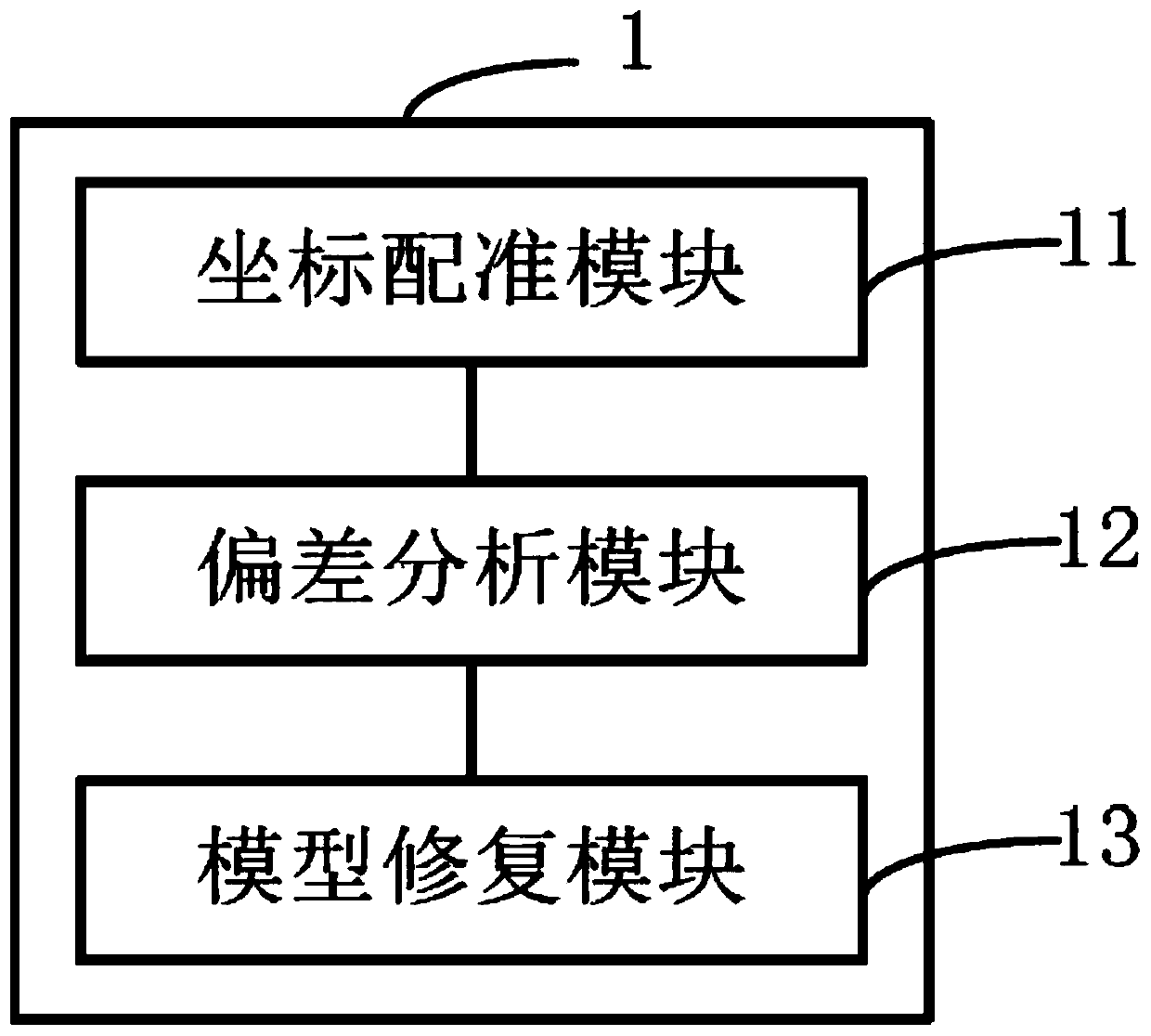

Embodiment 1

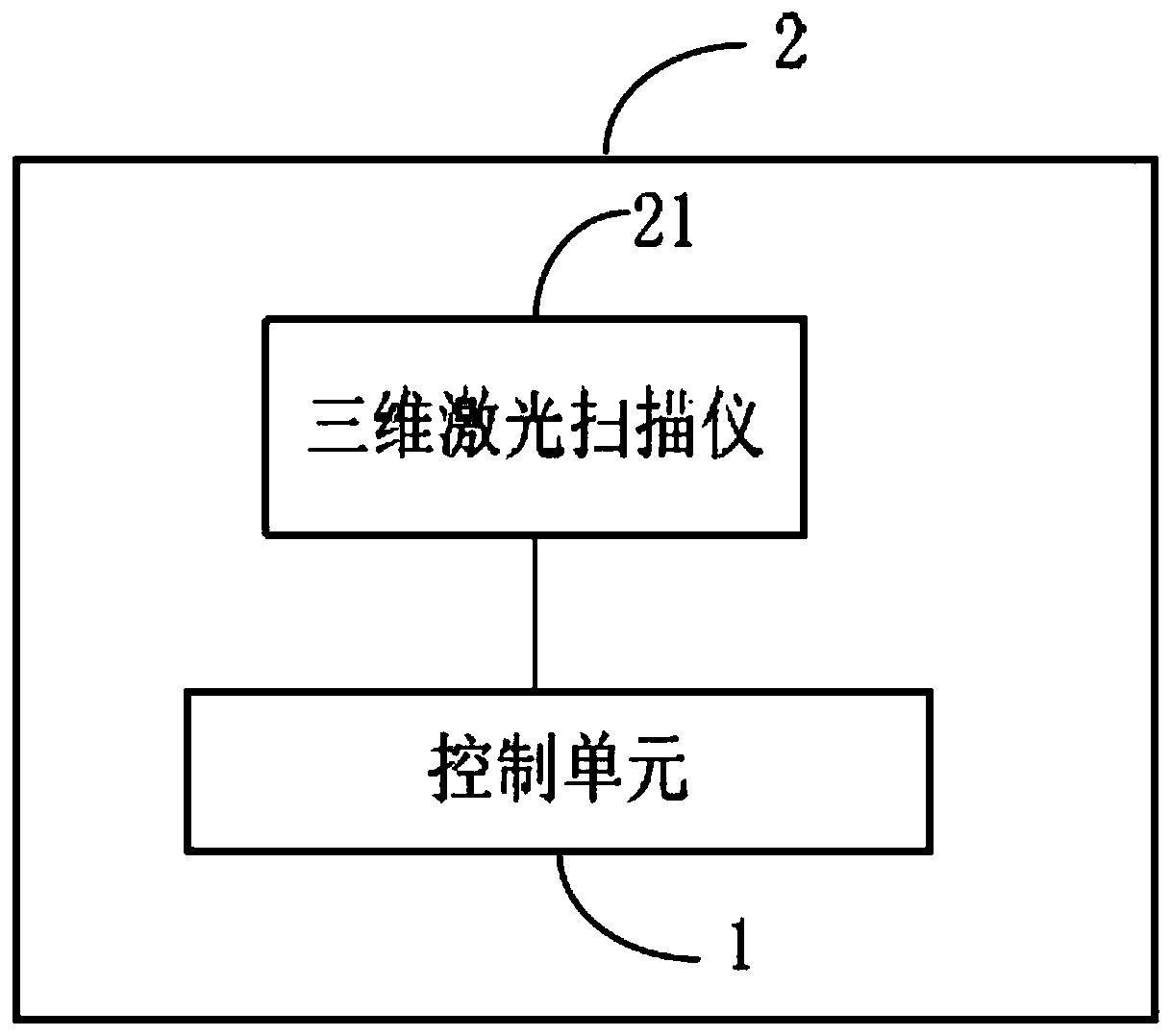

[0033] Based on Embodiment 1 of the present invention, Embodiment 2 of the present invention provides a repair system 2 for a three-dimensional model of a nuclear power plant, such as figure 2 As shown, specifically include:

[0034] The three-dimensional laser scanner 21 is used to obtain the real environment data of the nuclear power plant; the control unit 1 is used to obtain the three-dimensional model of the nuclear power plant to be repaired and the real environment data of the nuclear power plant, and coordinate the three-dimensional model of the nuclear power plant to be repaired and the real environment data of the nuclear power plant in the same space The overall three-dimensional space superposition and registration under the system; the deviation analysis module is used to perform missing and deviation evaluation analysis on the three-dimensional model of the nuclear power plant to be repaired and the real environment data of the nuclear power plant after the regis...

Embodiment 2

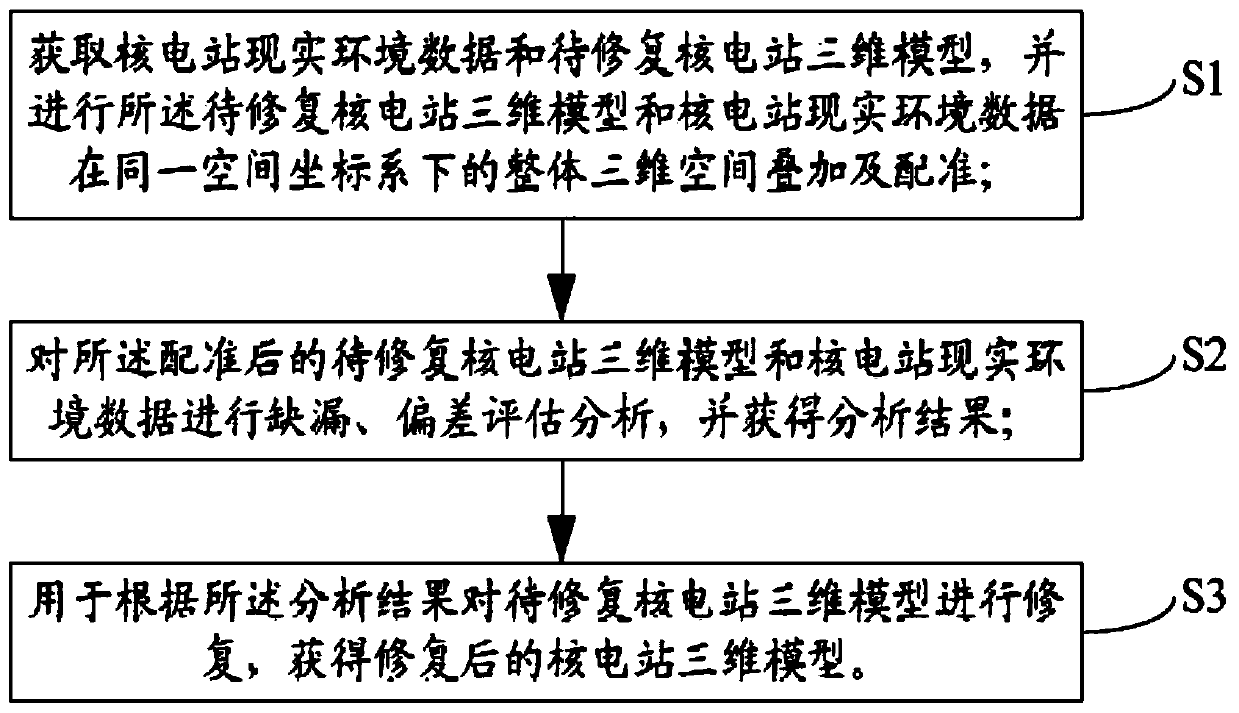

[0038] Based on Embodiment 2 of the present invention, Embodiment 3 of the present invention provides a method for repairing a three-dimensional model of a nuclear power plant, such as image 3 As shown, it specifically includes the following steps:

[0039] S1. Obtain the real environment data of the nuclear power plant and the three-dimensional model of the nuclear power plant to be repaired, and perform the overall three-dimensional space superposition and registration of the three-dimensional model of the nuclear power plant to be repaired and the real environment data of the nuclear power plant in the same space coordinate system;

[0040] S2. Carry out a gap and deviation assessment analysis on the 3D model of the nuclear power plant to be repaired and the real environment data of the nuclear power plant after the registration, and obtain the analysis results;

[0041] S3. Restoring the 3D model of the nuclear power plant to be repaired according to the analysis results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com