Compressor outlet parameter prediction modeling method based on width learning system

A technology for learning systems and exporting parameters, applied in the fields of electrical digital data processing, computer-aided design, special data processing applications, etc., can solve problems such as reducing system efficiency, increasing costs, and complex parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

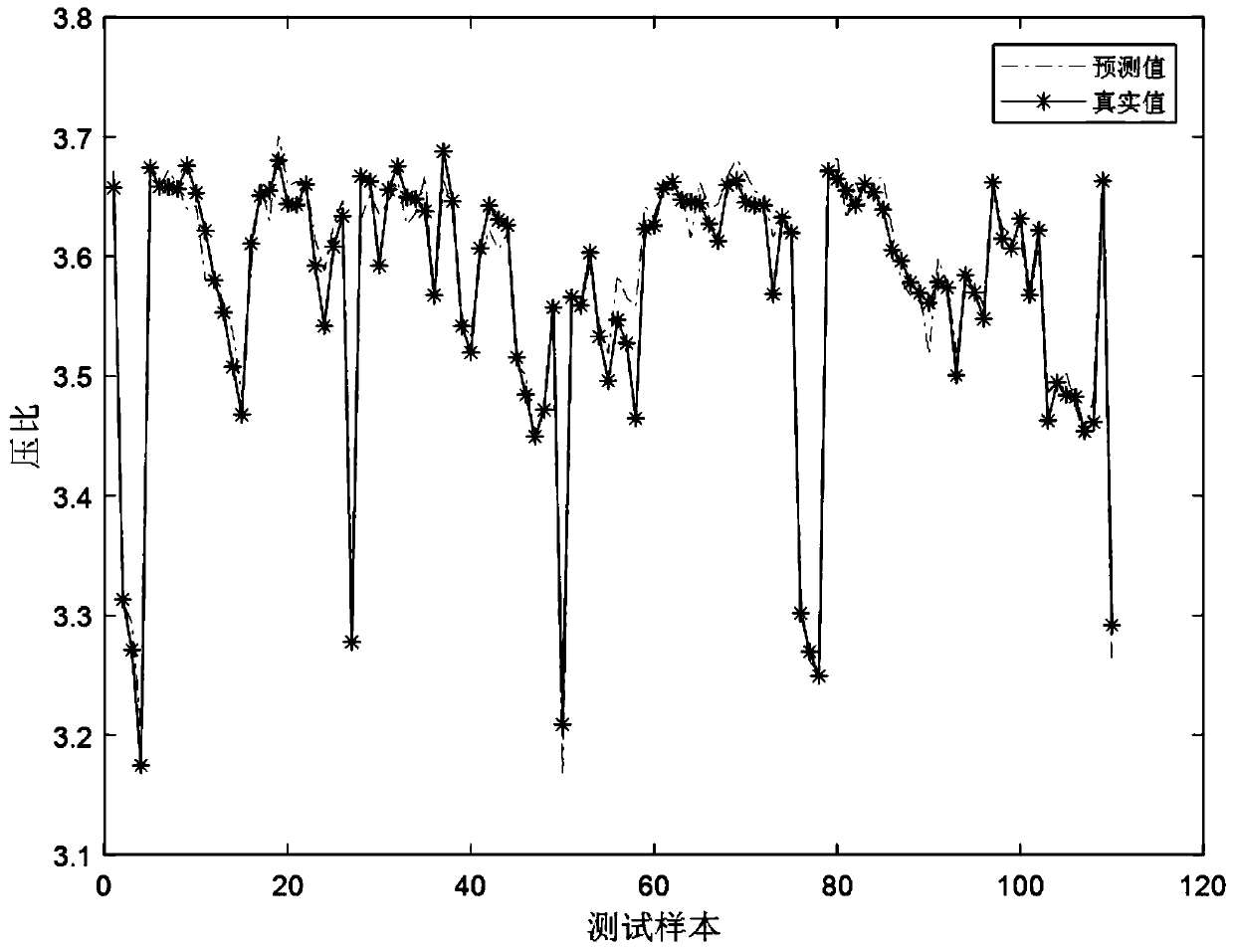

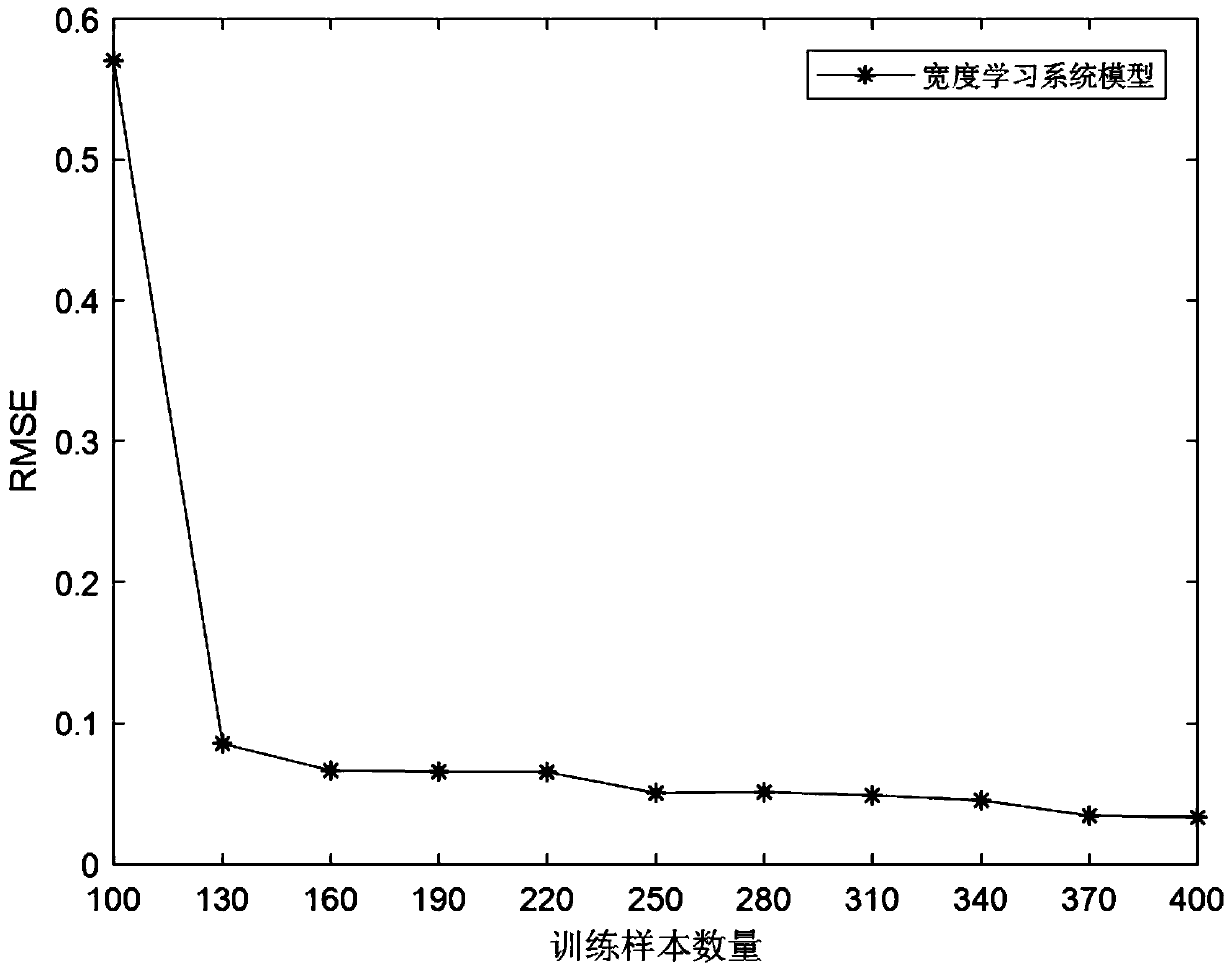

[0056]A predictive modeling method for compressor outlet parameters based on a wide learning system, using training set data to establish a compressor performance predictive model, when new training data is input into the model, the original model uses incremental learning algorithms to expand the network structure , to realize the online update of the model, which specifically includes the following steps:

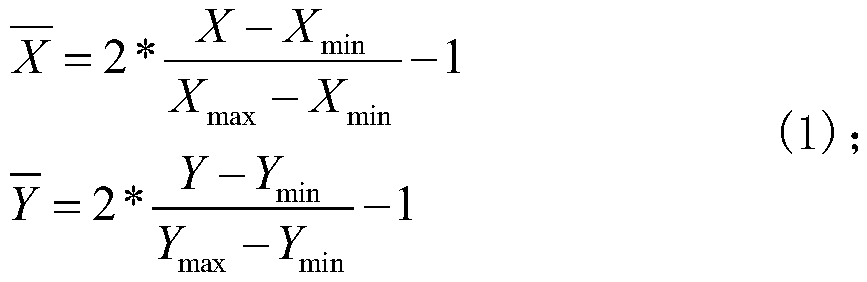

[0057] Step 1: collect data and preprocess it, the steps are as follows:

[0058] Step 1.1: Collect 510 groups of large-scale industrial multi-stage centrifugal compressor operating data (this data is collected from the actual operating unit of a steel plant), which is divided into a training set and a test set. The operating data includes input data variables and output data variables , the input data variables include: inlet pressure, inlet temperature and inlet flow, the output data variable is the output pressure ratio, 400 sets of data are selected as the training se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com