Two-dimensional Ga2S3 nanosheet-based bendable field-effect photoelectric transistor and preparation method thereof

A technology of phototransistors and nanosheets, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of peeling preparation, uncontrollable morphology and agglomeration of crystals, etc., to achieve improved photoelectric response performance, considerable economic benefits, time-saving and high efficiency consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

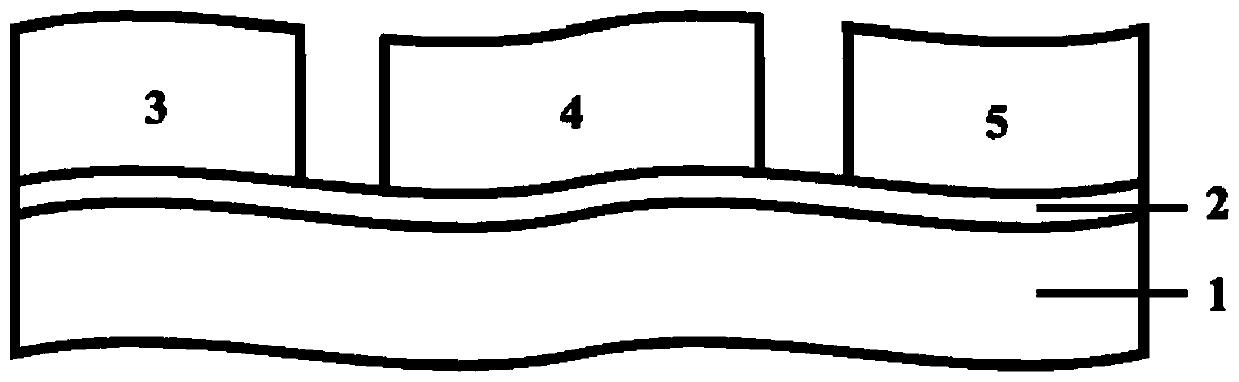

[0044] Based on the two-dimensional Ga of this embodiment 2 S 3 The bendable field-effect phototransistor of nanosheets from bottom to top, including PET substrate, two-dimensional Ga 2 S 3 Nanosheets, source, drain and gate electrodes.

[0045] The two-dimensional Ga 2 S 3 The number of nanosheet layers is 1, and the thickness is 5 nm; the source and drain electrodes are Ti metal layer and Au metal layer stacked sequentially from bottom to top, with thicknesses of 20 nm and 60 nm respectively; the gate electrode is stacked sequentially from bottom to top The Ni metal layer and the Au metal layer of the metal layer have a thickness of 50 nm and 100 nm, respectively; the length, width, and spacing of the source and drain electrodes correspond to 80 nm, 80 nm, and 300 nm; the length and width of the gate electrode are respectively 80nm and 80nm.

[0046] Its preparation method comprises the following steps:

[0047] (1) Clean the Si substrate to remove surface residues an...

Embodiment 2

[0066] Based on the two-dimensional Ga of this embodiment 2 S 3 The bendable field-effect phototransistor of nanosheets from bottom to top, including PDMS substrate, two-dimensional Ga 2 S 3 Nanosheets, source, drain and gate electrodes.

[0067] The two-dimensional Ga 2 S 3 The number of nanosheet layers is 3 layers, and the thickness is 7 nm; the source and drain electrodes are Ti metal layer and Au metal layer stacked sequentially from bottom to top, with thicknesses of 25 nm and 70 nm respectively; the gate electrode is stacked sequentially from bottom to top The Ni metal layer and the Au metal layer of the metal layer have a thickness of 40 nm and 80 nm, respectively; the length, width, and spacing of the source and drain electrodes are 90 nm, 60 nm, and 360 nm, respectively; the length and width of the gate electrode are 100 nm, respectively. nm and 60 nm.

[0068] Its preparation method comprises the following steps:

[0069] (1) Clean the Si substrate, remove th...

Embodiment 3

[0087] Based on the two-dimensional Ga of this embodiment 2 S 3 The bendable field-effect phototransistor of nanosheets from bottom to top, including ITO substrate, two-dimensional Ga 2 S 3 Nanosheets, source, drain and gate electrodes.

[0088] The two-dimensional Ga 2 S 3 The number of nanosheet layers is 2 layers, and the thickness is 6 nm; the source and drain electrodes are Ti metal layer and Au metal layer stacked sequentially from bottom to top, with thicknesses of 30 nm and 80 nm respectively; the gate electrode is stacked sequentially from bottom to top The Ni metal layer and the Au metal layer of the metal layer have a thickness of 45 nm and 90 nm respectively; the length, width and spacing of the source and drain electrodes are 100 nm, 70 nm and 340 nm respectively; the length and width of the gate electrode are respectively 90nm and 70nm.

[0089] Its preparation method comprises the following steps:

[0090] (1) Clean the Si substrate, remove the surface re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com