Middle frame and terminal equipment

An outer frame and end-to-end technology, applied in the field of machinery, can solve the problem of long time consumption of the middle frame, and achieve the effects of short time consumption, simple processing technology and simple structure and form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

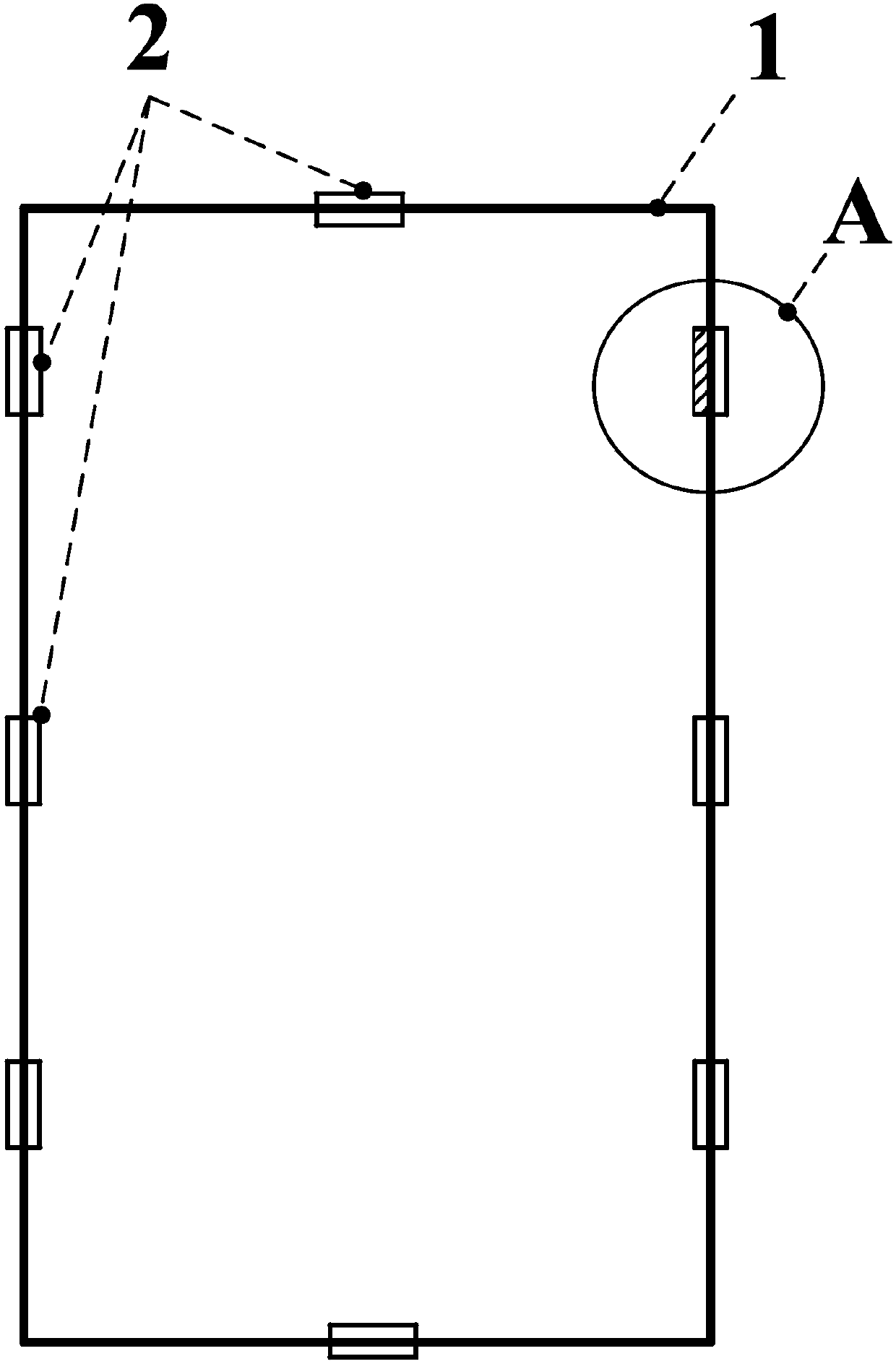

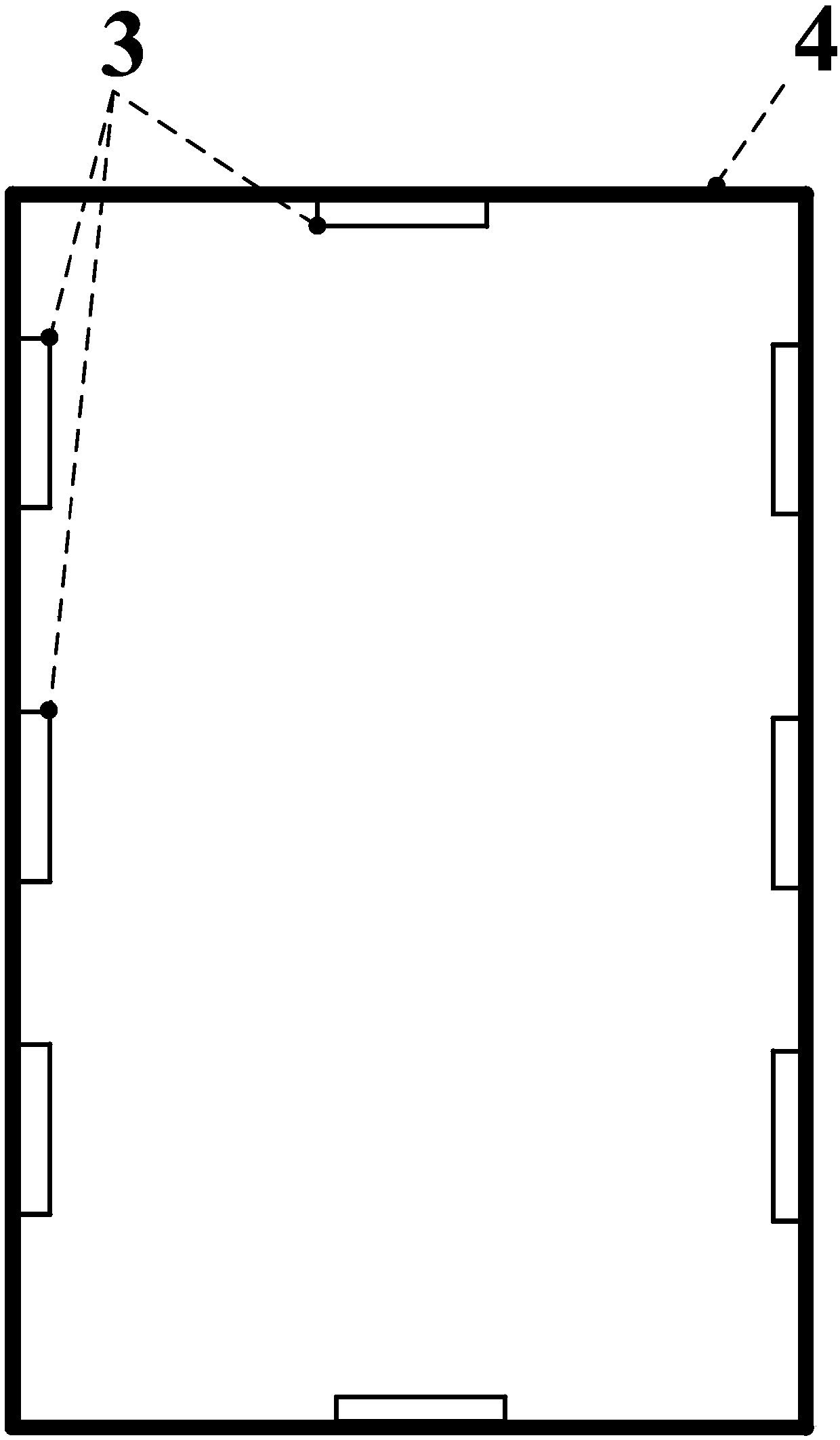

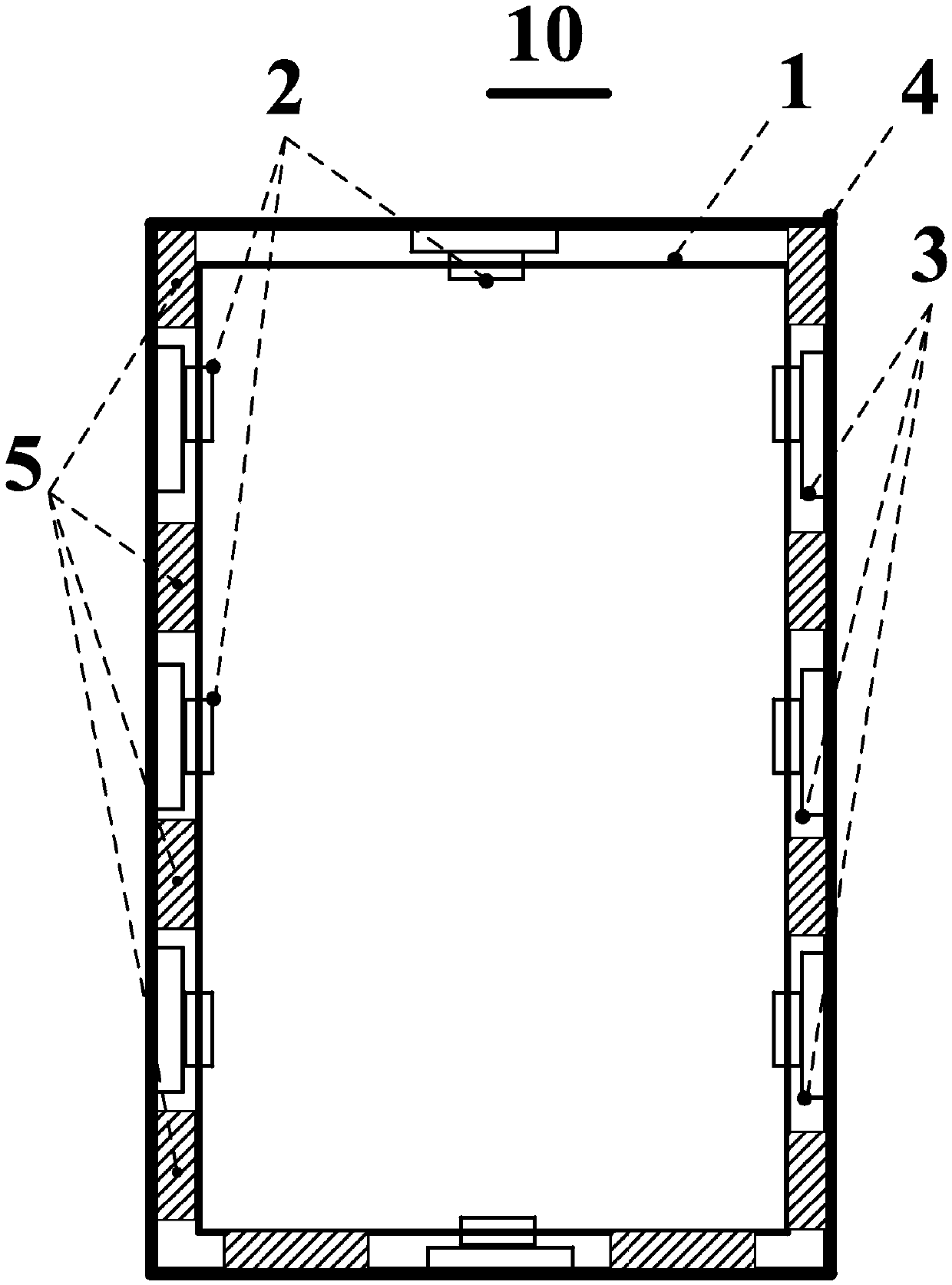

[0037] See Figure 1 to Figure 3 as shown, figure 1 What is shown is a schematic diagram of a middle plate of a middle frame and at least one middle piece disclosed in the embodiment of the present application, figure 2 What is shown is a schematic diagram of at least one welding station and an outer frame of a middle frame disclosed in the embodiment of the present application, image 3 What is shown is an overall schematic diagram of a middle frame disclosed in the embodiment of the present application.

[0038] exist Figure 1 to Figure 3 In the illustrated embodiment, the middle frame 10 provided by the embodiment of the present application includes a middle plate 1, at least one intermediate piece 2, at least one welding station 3 and an outer frame 4, wherein at least one middle piece 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com