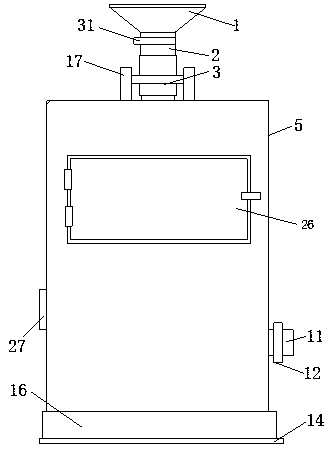

High-efficiency liquid mixing device for processing of raw materials

A liquid mixing and high-efficiency technology, applied in the field of machinery, can solve the problems of low mixing efficiency and achieve the effect of improving mixing efficiency, improving stirring and mixing effect, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

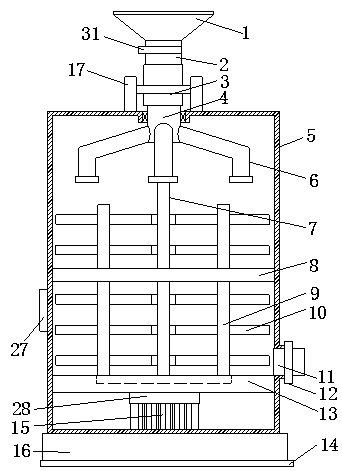

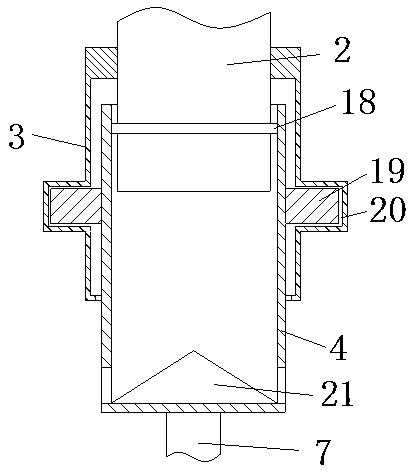

[0027] Embodiment: First, the staff starts the drive motor 15 through the controller switch, and the drive motor 15 drives the first connecting shaft 7 to rotate after being decelerated by the reducer 28, and the rotating first connecting shaft 7 drives the liquid pipe 4 and the rotary block 19 to connect The casing 3 rotates, the liquid pipe 4 drives multiple second liquid inlet pipes 6 to rotate, the staff can add the liquid to be mixed into the conical liquid inlet hopper 1, open the solenoid valve 31, and the liquid passes through the first liquid inlet pipe 2 enters the liquid distribution pipe 4, and flows into the second liquid inlet pipe 6 through the conical liquid guide block 21, and pours it evenly into the main body 5 of the mixing tank through the second liquid inlet pipe 6, and the rotating first A connecting shaft 7 drives the second external gear 24 to rotate, and the second external gear 24 drives a plurality of first external gears 22, the second connecting sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com