Welding assisting guiding device

A guide device and guide tube technology, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of low welding efficiency, poor quality, difficult welding, etc. Improve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

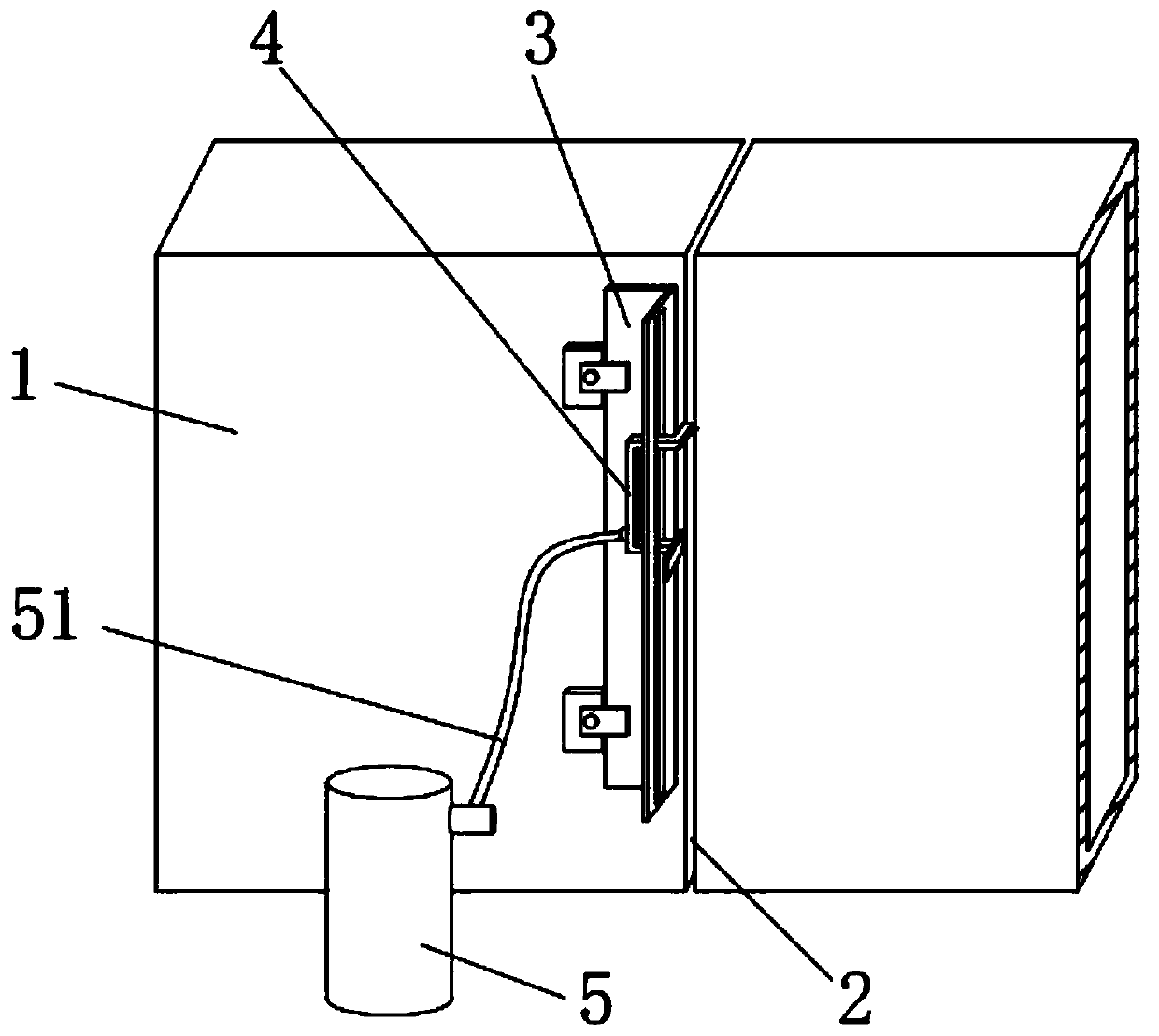

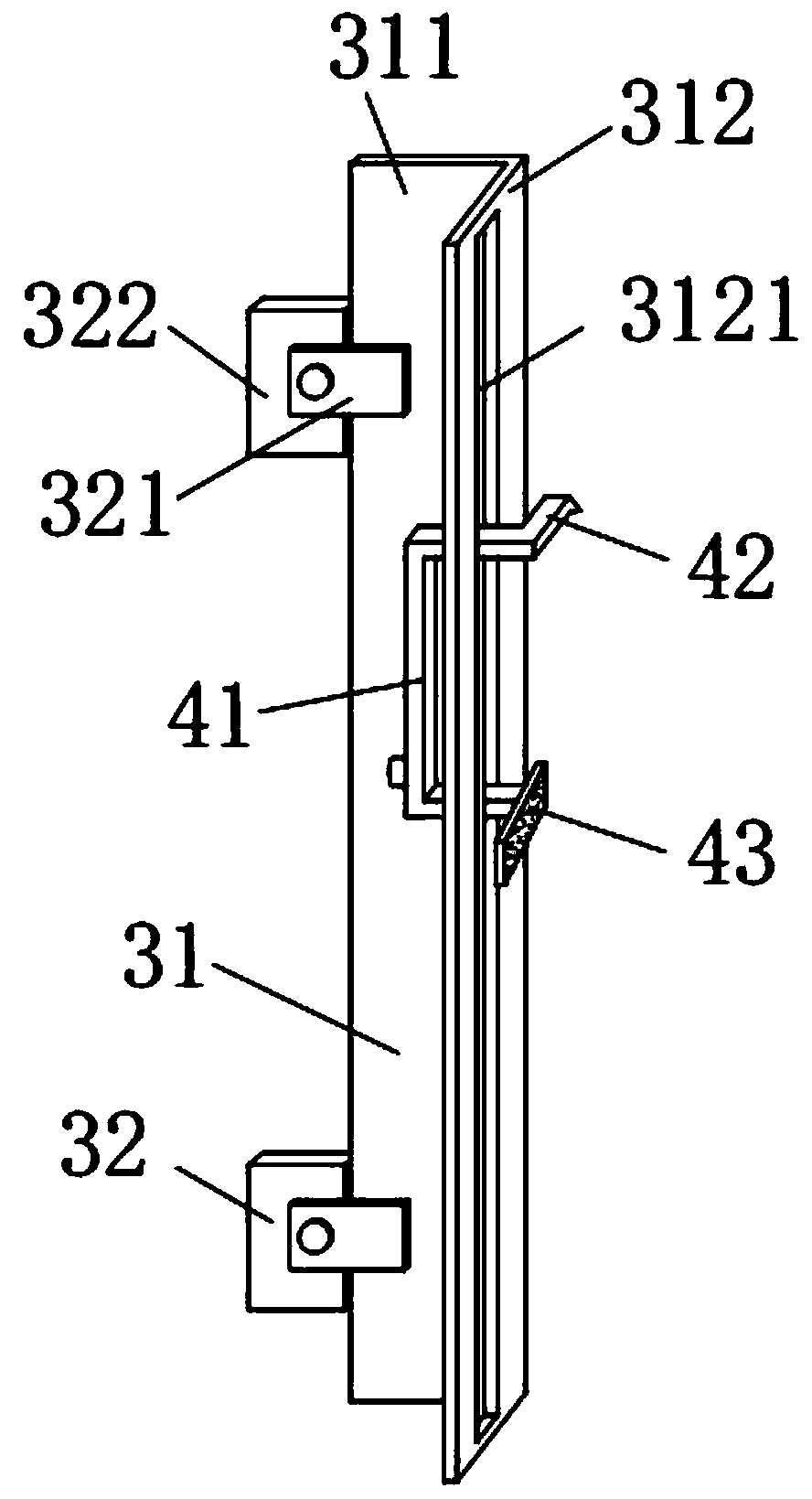

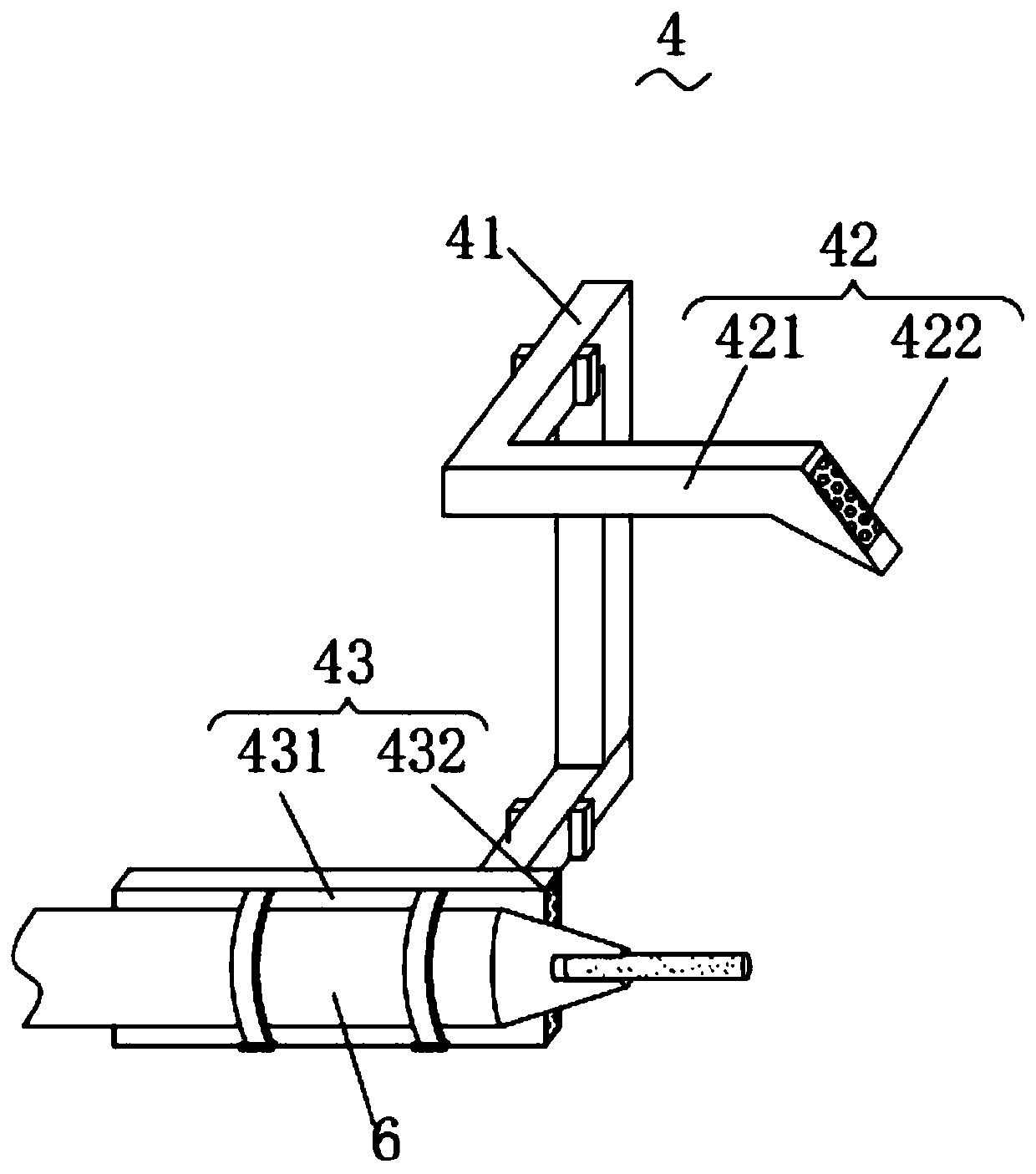

[0023] A welding auxiliary guiding device, comprising a weld alignment mechanism 3, the weld alignment mechanism 3 includes an angle steel 31 and a fixing mechanism 32; As the guiding reference of the welding torch 6; the side of the angle steel 31 is connected with a plurality of fixing mechanisms 32, and the fixing mechanism 32 includes a magnet 322 and a connecting plate 321, and the angle steel 31 is connected to the magnet 322 through the connecting plate 321 , the magnet 322 is adsorbed and connected to the workpiece 1 to be processed;

[0024] The magnet 322 is used to realize the non-destructive connection between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com