Prefabricated concrete T-beam U-shaped cable slot mould

A technology of prefabricated concrete and cable troughs, applied in molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of inconvenient demoulding, achieve simple structure, reduce mold costs, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

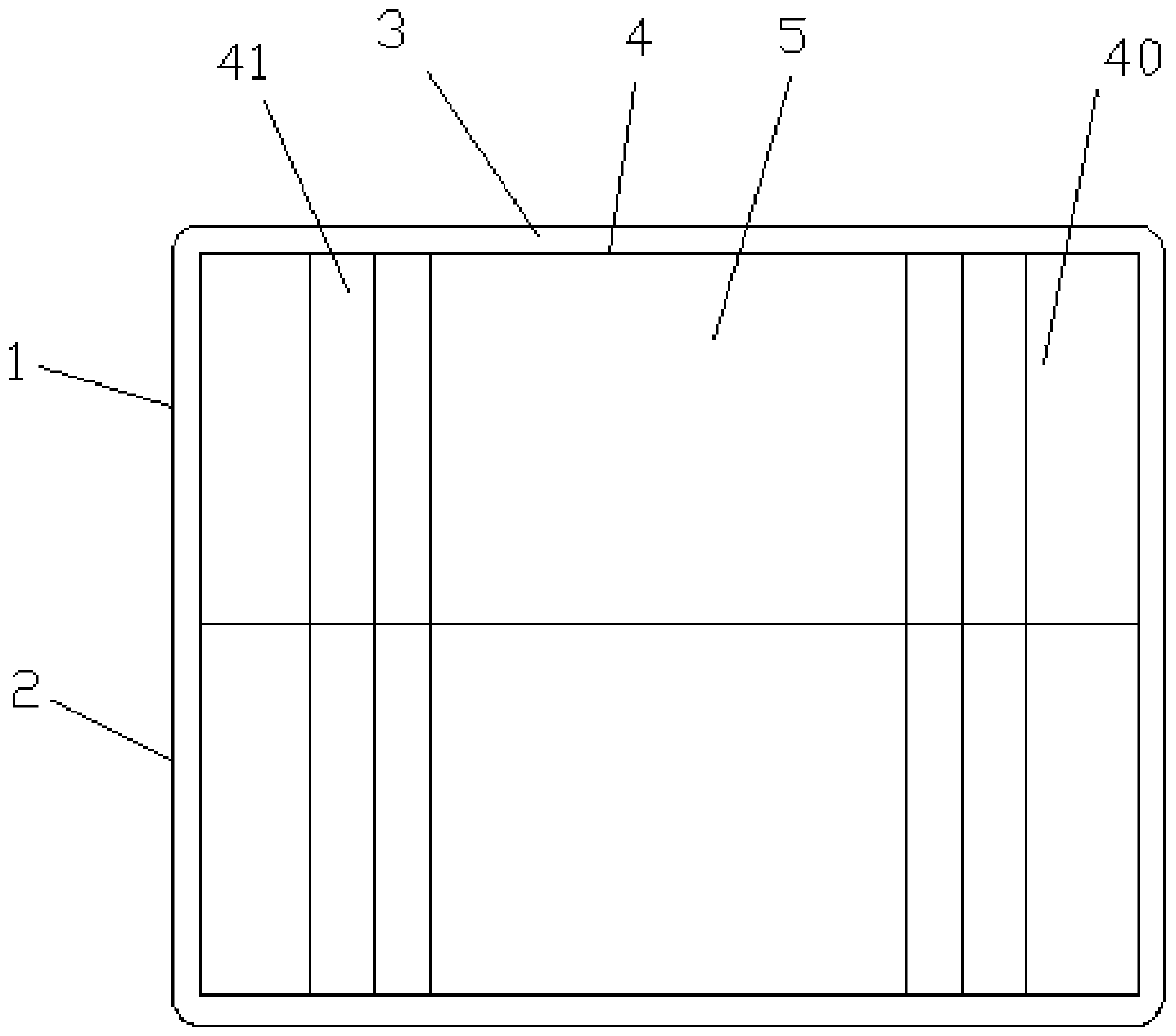

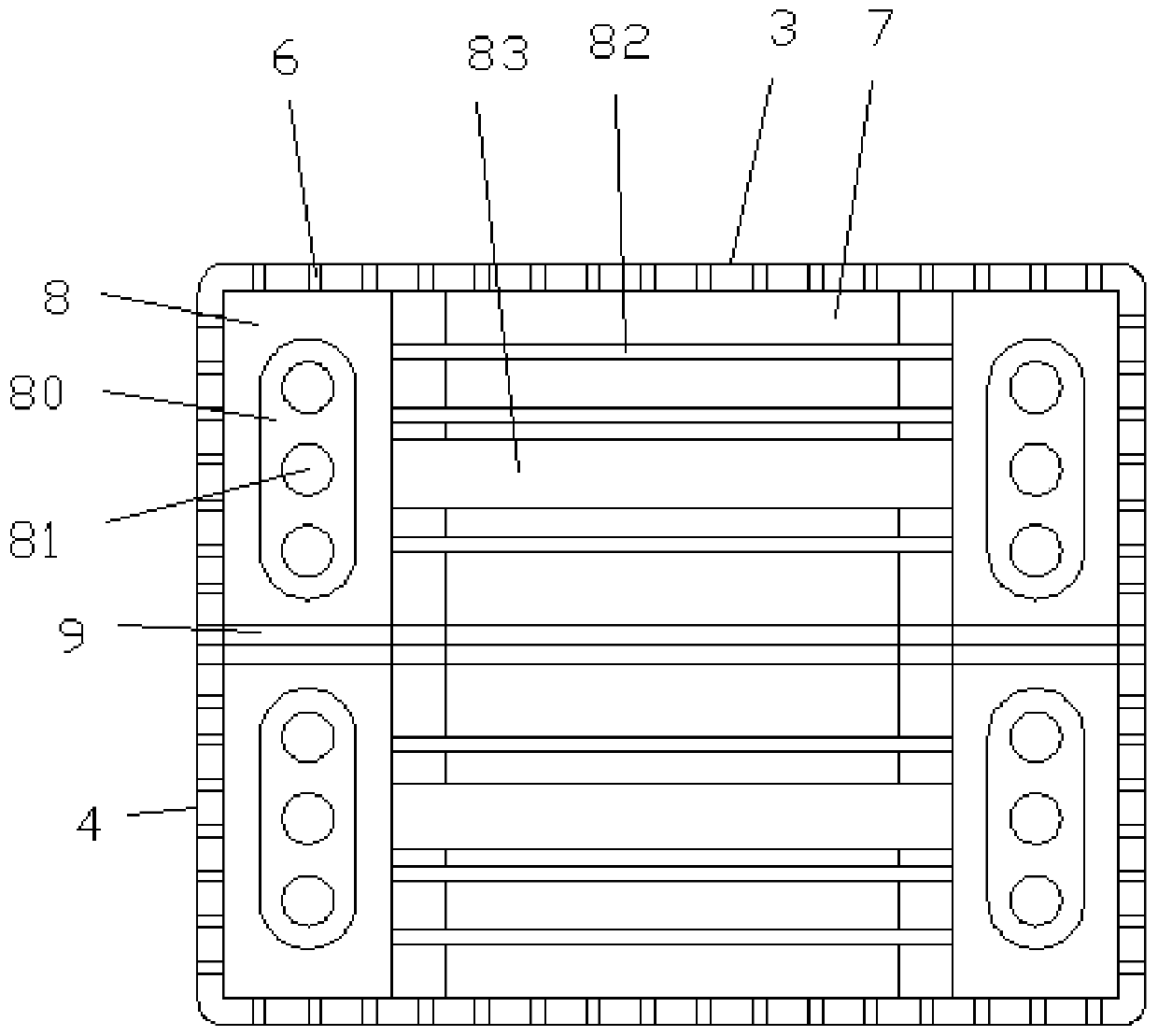

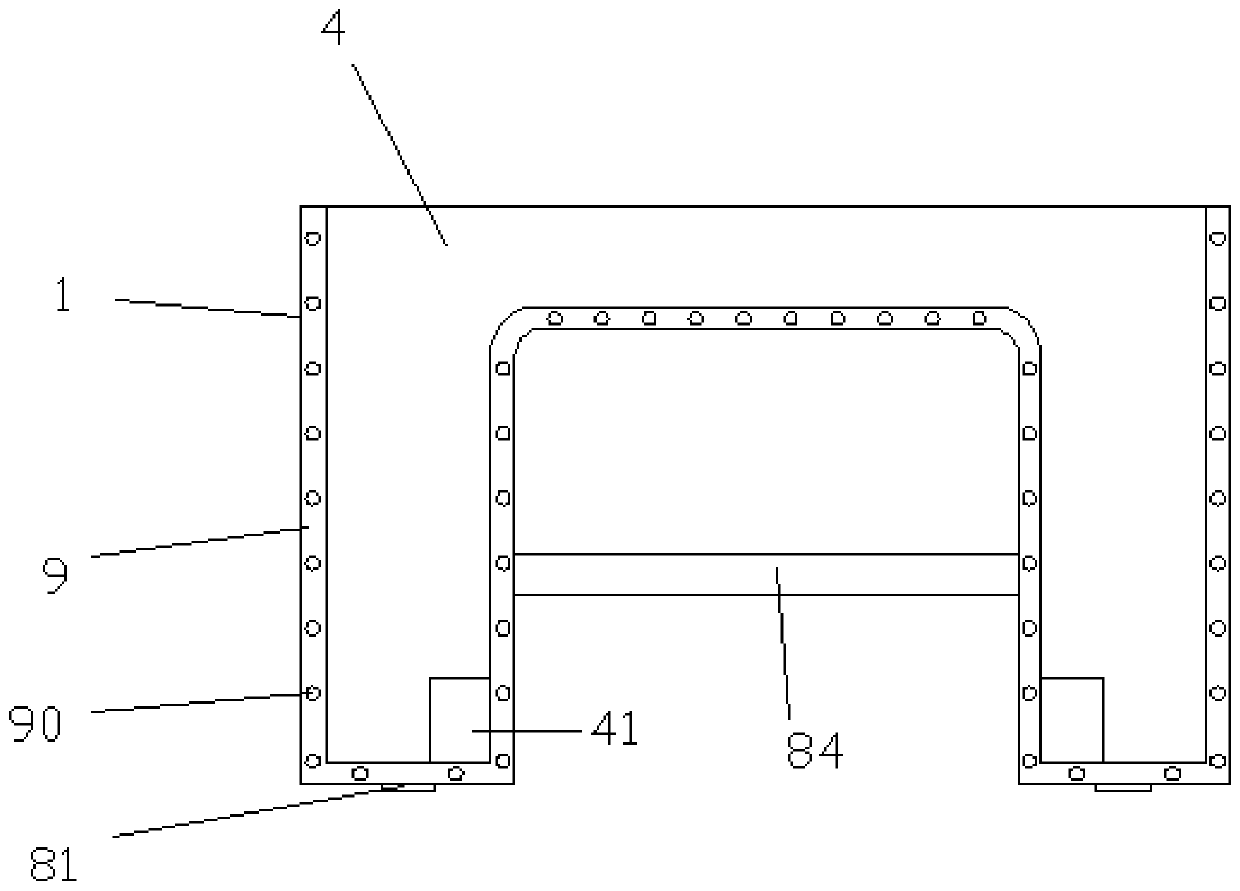

[0020] Referring to the accompanying drawings, a prefabricated concrete T-beam U-shaped cable duct mold of the present invention comprises a front split mold 1 and a rear split mold 2, and a rear split mold is provided behind the front split mold 1 2. The front side split mold 1 is provided with a frame 3, the inner side of the frame 3 is provided with a mold groove 4, and the bottom of the mold groove 4 is provided with a boss 5, and the front side split mold 1 The bottom is provided with a backboard 7, a first reinforcing rib 6 is provided between the backboard 7 and the frame 3, and a plurality of bosses 8 are arranged on the backboard 7, and the front split mold 1 and the rear split mold A connecting surface 9 is provided on the contact surface of the body mold 2, and the internal structures of the front split mold 1 and the rear split mold 2 are symmetrical to each other.

[0021] Wherein, the mold groove 4 is a 'U' shape, deep grooves 40 are arranged on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com