A bearing double-sided grease injection and capping integrated machine and a grease injection and capping method thereof

An all-in-one machine and gland technology, applied in mechanical equipment, engine components, engine lubrication, etc., can solve the problems of inability to achieve automatic feeding and double-sided synchronous gland, and improve gland efficiency and uniformity. To ensure continuous and stable operation, stable and uniform grease injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing.

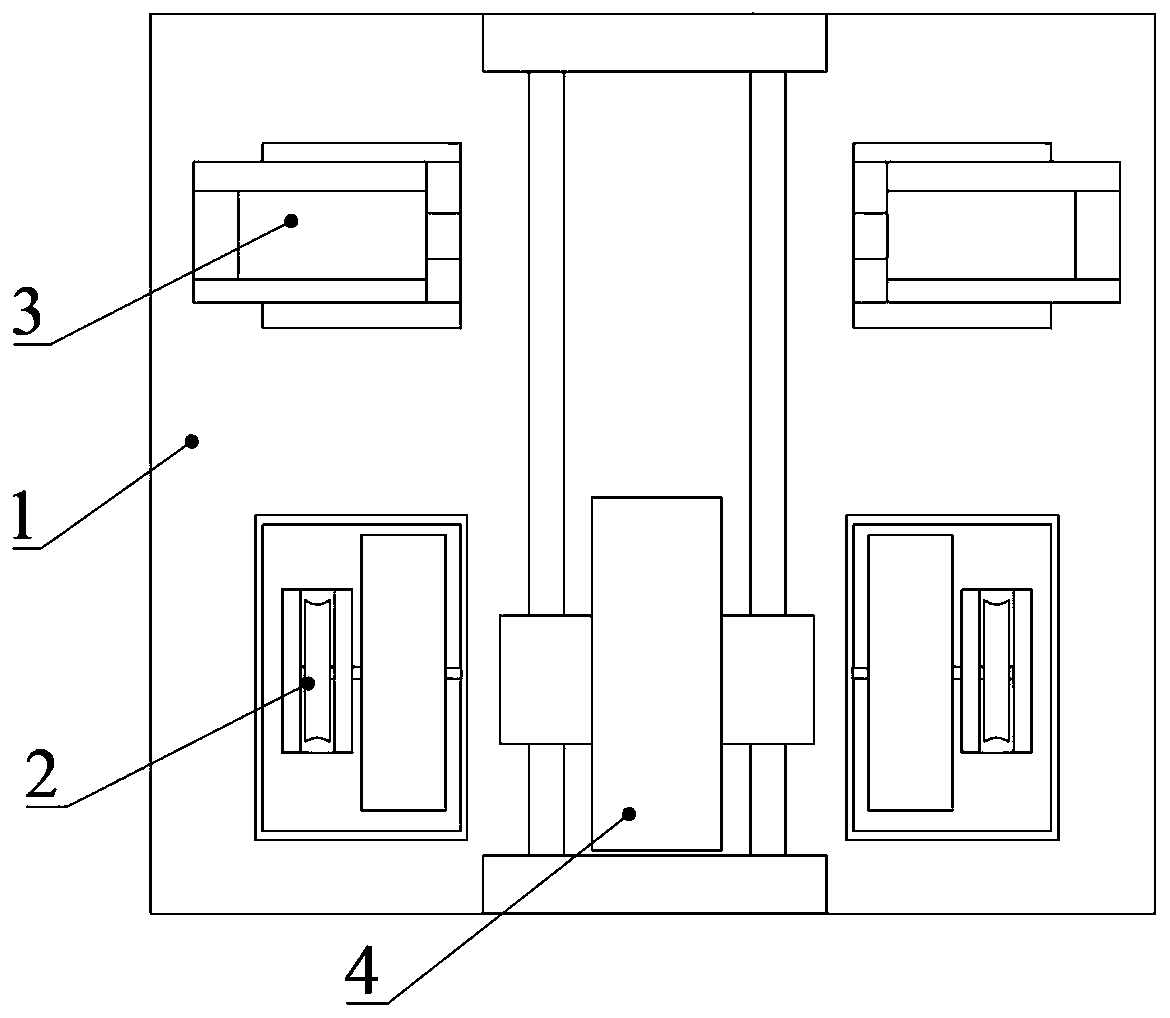

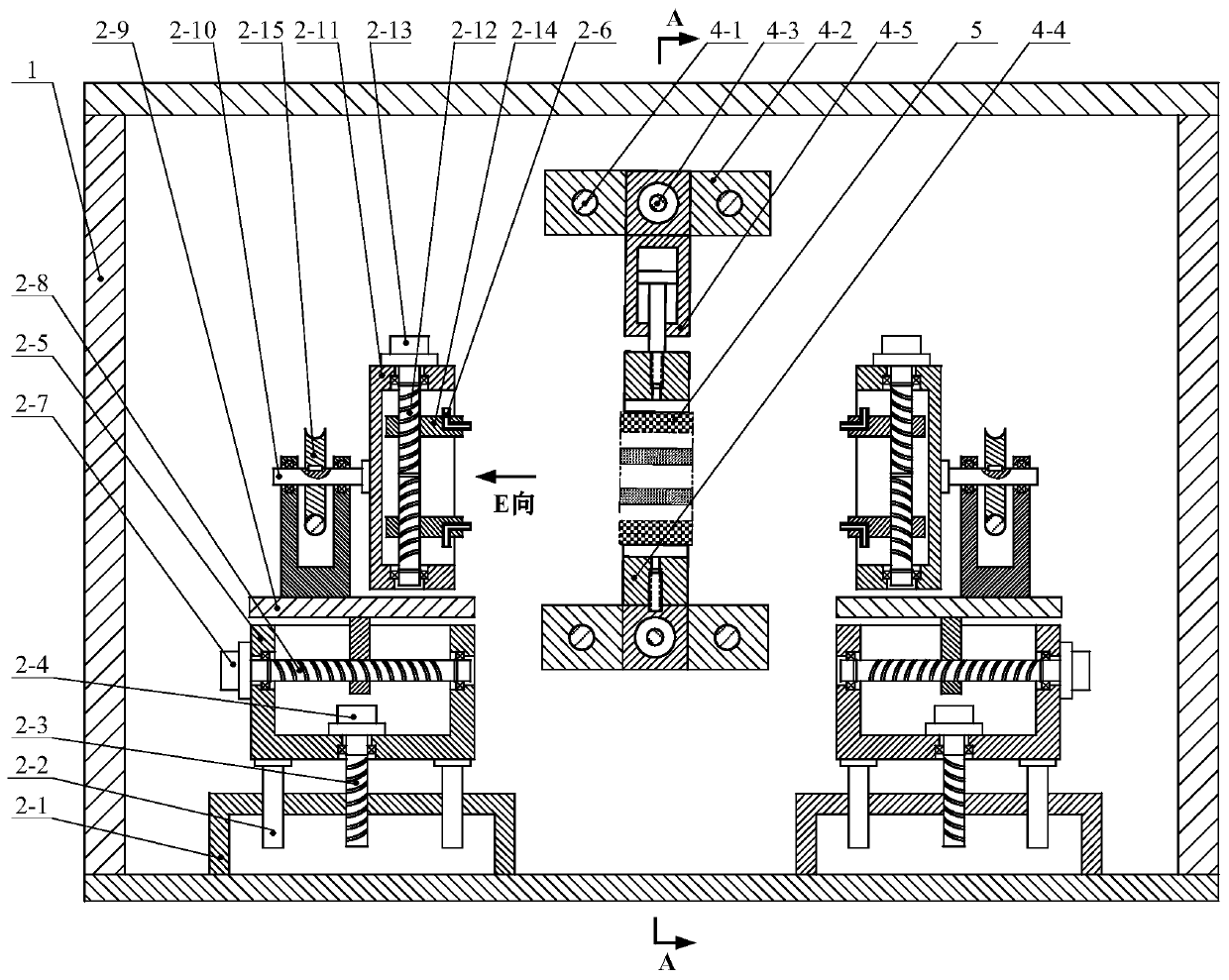

[0052] Such as figure 1 As shown in the figure, an integrated bearing double-sided grease injection and capping machine includes a frame 1, a grease injection module 2, a gland module 3, a station switching mechanism 4 and a controller. The grease injection module 2 and the capping module 3 are arranged along the station switching direction of the station switching mechanism 4 .

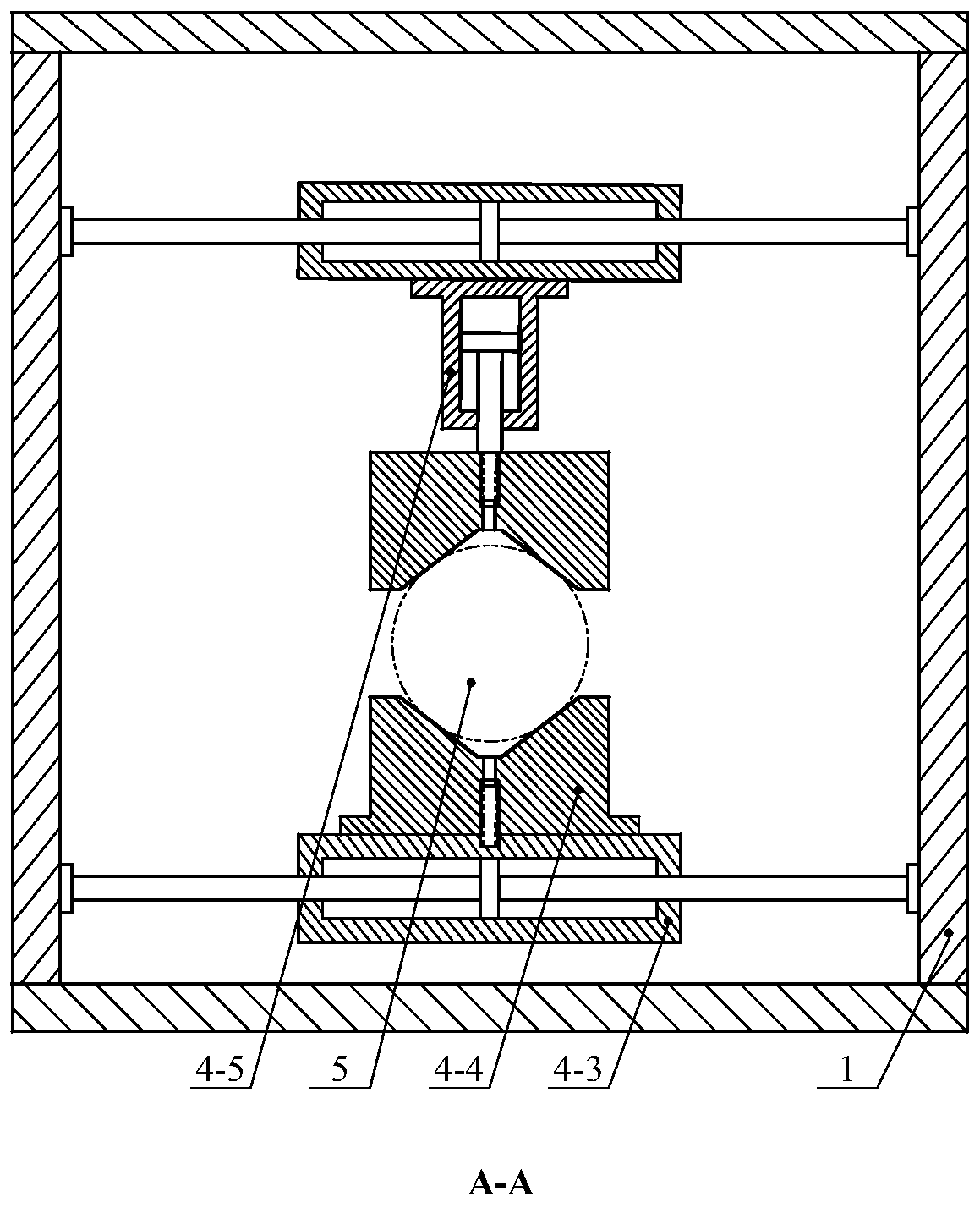

[0053] Such as figure 1 , 2 , 3 and 5, the station switching mechanism 4 includes a station traverse assembly and a clamping assembly. The station traverse assembly includes a clamping guide column 4-1, a clamping slider 4-2 and a moving cylinder 4-3. The two clamping guide columns 4-1 arranged horizontally and at the same height are fixed with the frame 1. The two clamping sliders 4-2 and the two clamping guide posts 4-1 constitute sliding pairs respectively. Mobile cylinder 4-3 adopts doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com