Online full-automatic cleaning device and method for lithium battery slit extrusion type coating die head

An online die head and cleaning device technology, which is applied to the surface coating liquid device, electrode extrusion, lithium battery, etc., can solve the impact of coating stability and coating quality and safety, affecting temperature and humidity and cleanliness, Equipment or personnel injury and other problems, to achieve the effect of stable equipment and personnel safety, stable cleaning effect, and no need for human operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

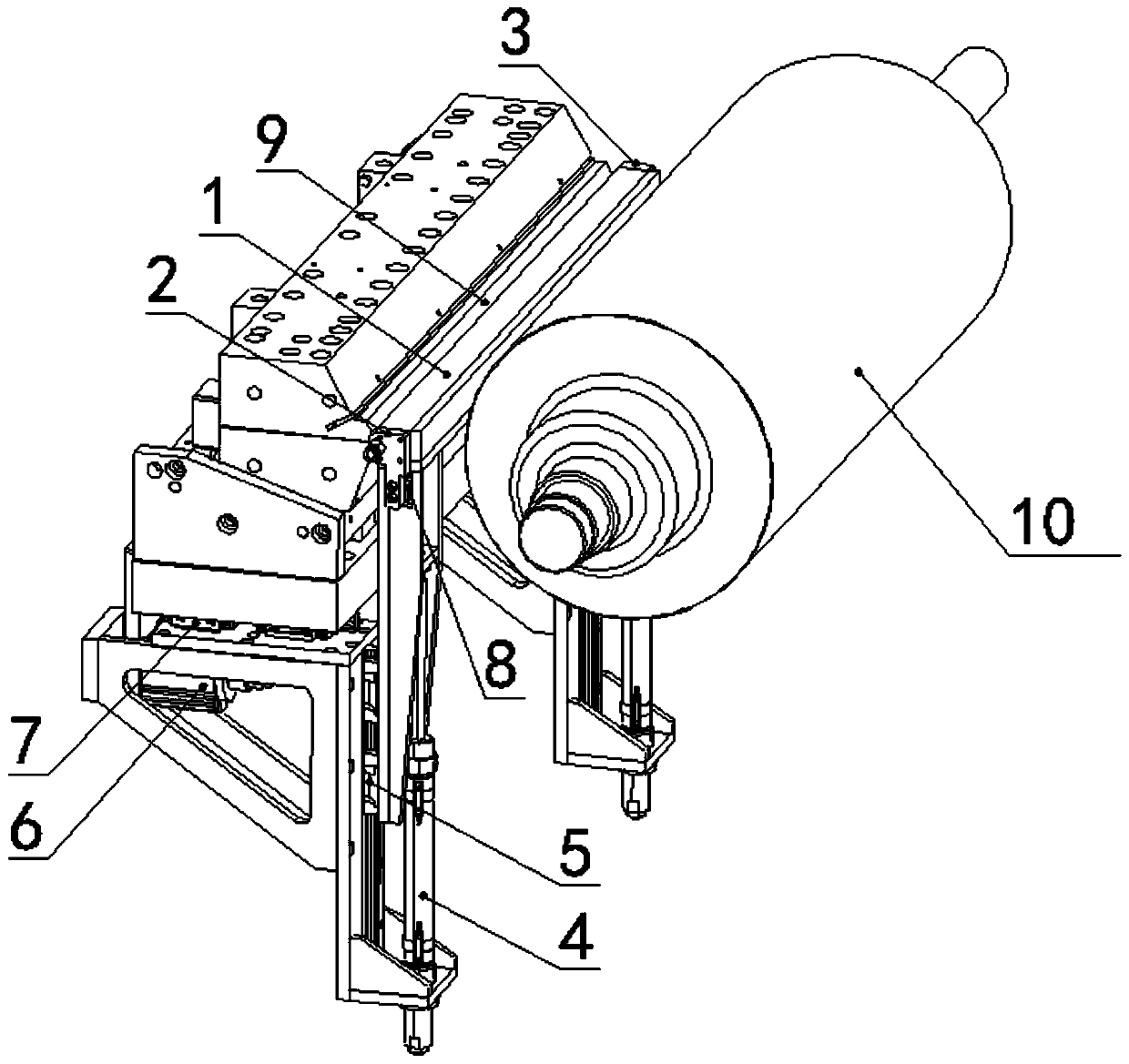

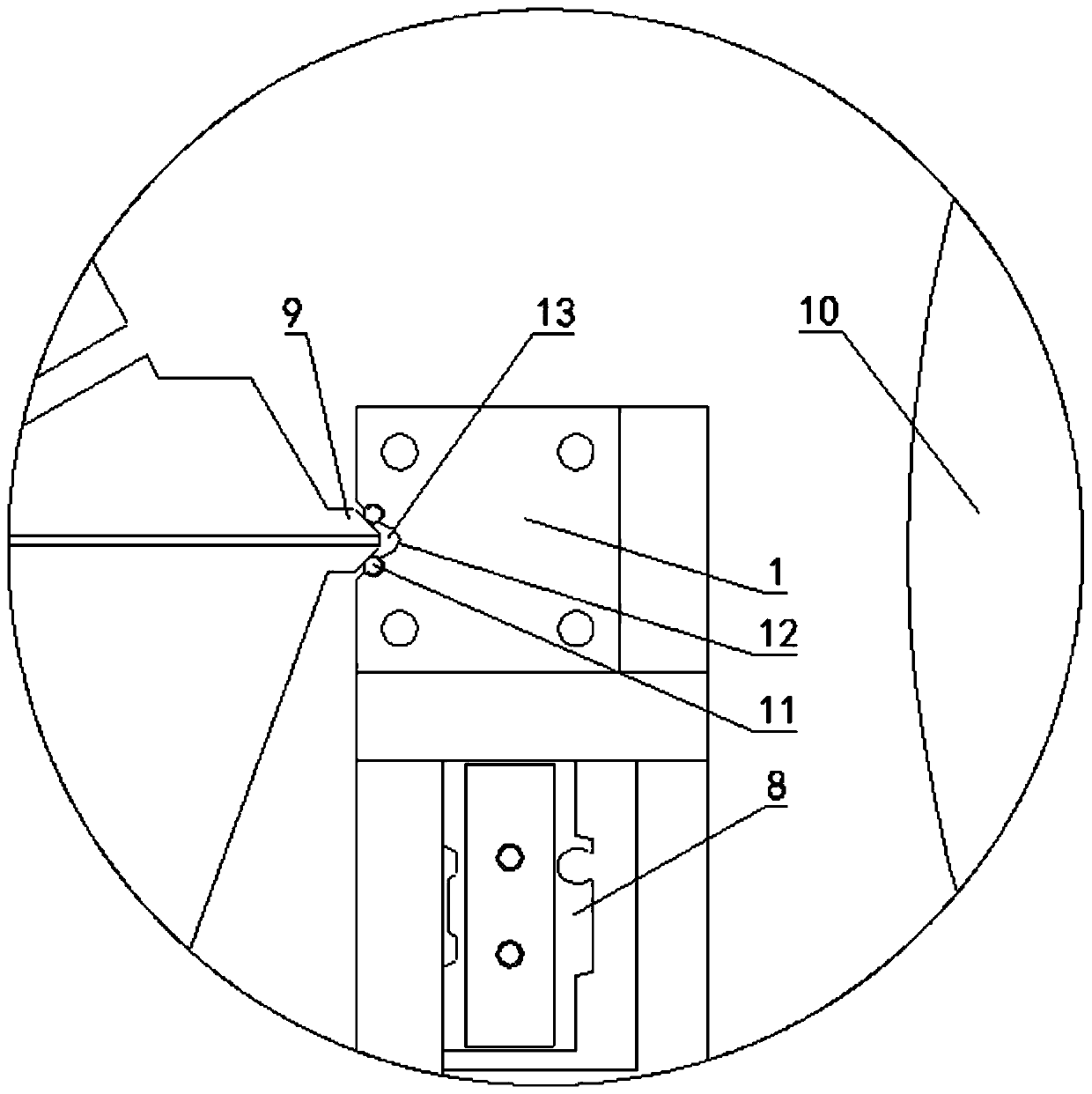

[0024] The invention is an online automatic cleaning device for a lithium battery slit extrusion coating die head, such as figure 1 and figure 2 As shown, it includes: a cleaning chamber plate 1, the cleaning chamber plate 1 is composed of a sealing strip 11 and a diversion arc groove 12; the sealing strip 11 is inlaid or inserted in parallel on the upper and lower sides of the diversion arc groove, and Corresponding to the upper and lower slopes of the die lip; the cleaning cavity plate 1 contacts and presses the upper and lower slopes of the die lip 9 to seal, and the die lip 9 and the diversion arc groove 12 form a closed cleaning tunnel 13; closed cleaning One end of the tunnel is used as the inlet for cleaning liquid and high-pressure gas, and the other end is used as the waste discharge outlet. The inlet and outlet are sealed with the inlet sealing plate 2 and the outlet sealing plate 3 respectively. The inlet sealing plate 2 and the outlet sealing plate 3 are inlaid wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com