Welding method for YG8 hard alloy workpiece and DC53 cold work die steel workpiece

A technology of cold working die steel and hard alloy, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of low welding rate and achieve the effect of good strength and no cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

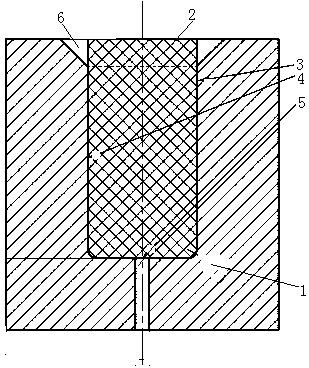

[0028] Embodiment one, see figure 1 , a YG8 hard alloy workpiece and DC53 cold work die steel workpiece welding method: the first step, remove the oil stain and oxide film at the welding place of the YG8 hard alloy workpiece 1 to be welded, and remove the DC53 cold work die steel workpiece 2 to be welded The oil stain and oxide film at the welding place; in the second step, the welding place of the YG8 hard alloy workpiece to be welded and the welding place of the DC53 cold work die steel workpiece to be welded are butted together with a gap to form a weldment pair. The gap is filled with pure copper; specifically, a connecting hole 3 is opened in a YG8 hard alloy workpiece 1, and a connecting head 4 is formed on a DC53 cold work die steel workpiece. The connection holes are blind holes. An air extraction hole 5 is provided on the bottom wall of the connecting hole. The connector extends vertically. A bell mouth section 6 is arranged at the open end of the connecting hole. ...

Embodiment 2

[0030] Embodiment two, the difference with embodiment one is:

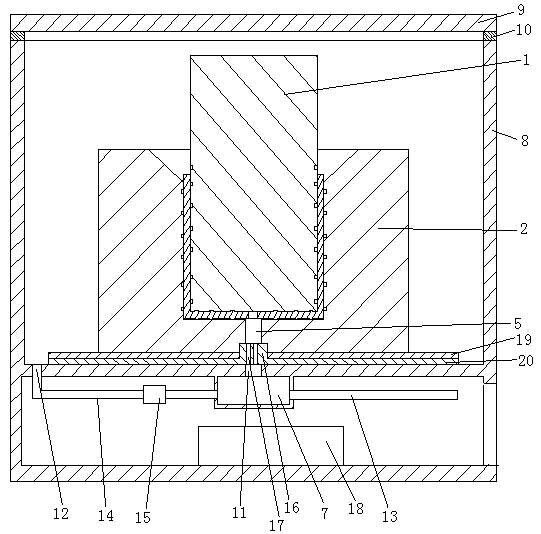

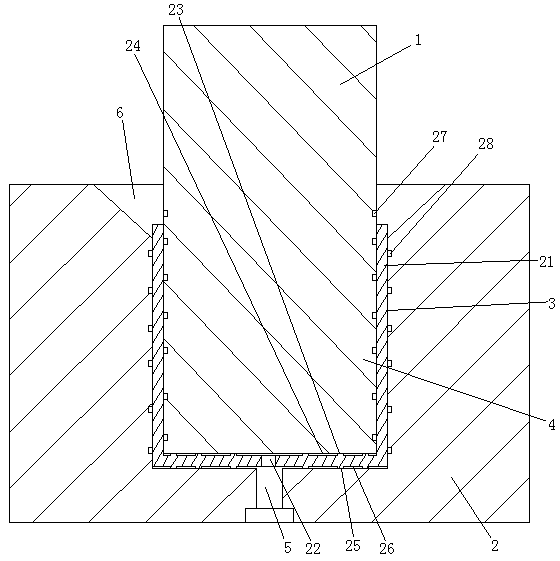

[0031] see figure 2 and image 3, the present embodiment is accomplished by a brazing device, which includes a vacuum chamber, a confluence chamber 7 and a heater for heating the vacuum chamber. The vacuum chamber includes a barrel body 8 and a barrel cover 9 . A sealing ring 10 is provided between the bung and the staving. The sealing ring is fixed on the upper end face of the staving, and the bung rests on the sealing ring. The barrel cover is sealed and connected with the barrel body by pressing the sealing ring to form a pressure difference between the outside and the inside of the vacuum chamber by evacuating the vacuum chamber. The vacuum chamber is provided with a first air outlet 11 and a second air outlet 12 . The confluence chamber cavity is provided with a vacuum port 13 and a pressure gauge (not shown in the figure). The first air outlet communicates with the confluence chamber. The second air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com