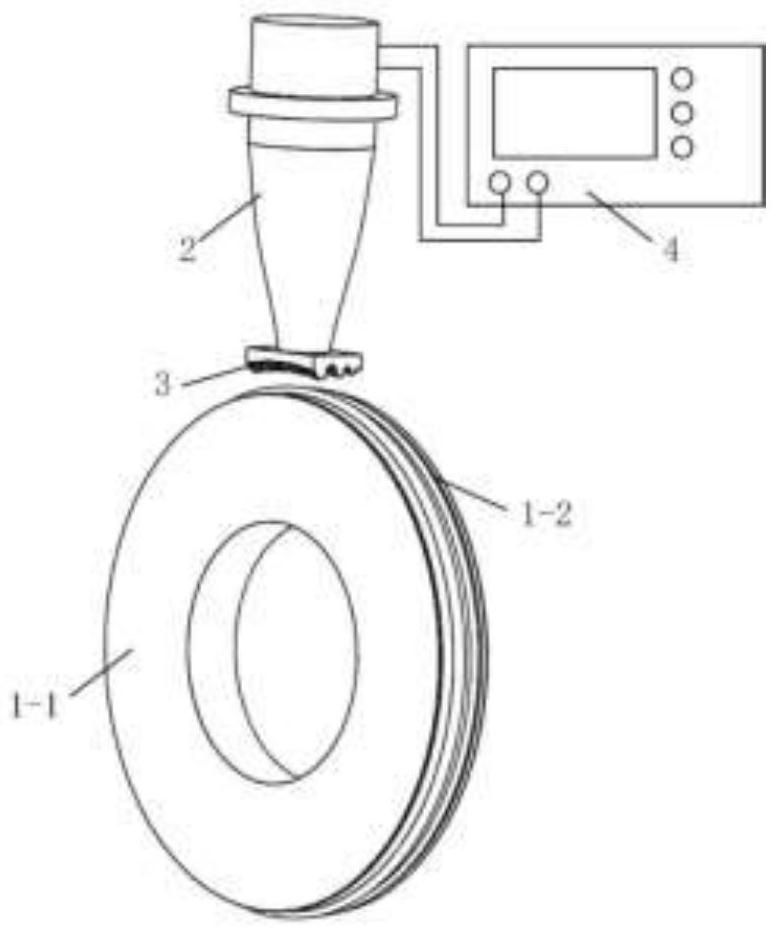

Device and method for ultrasonic brazing of super-hard abrasive grinding wheel

A super-hard abrasive and ultrasonic technology, used in grinding devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of high brazing temperature, large thermal deformation of grinding wheels, and changes in the position of abrasive grains. The effect of small welding heat effect, low brazing temperature and uniform contour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

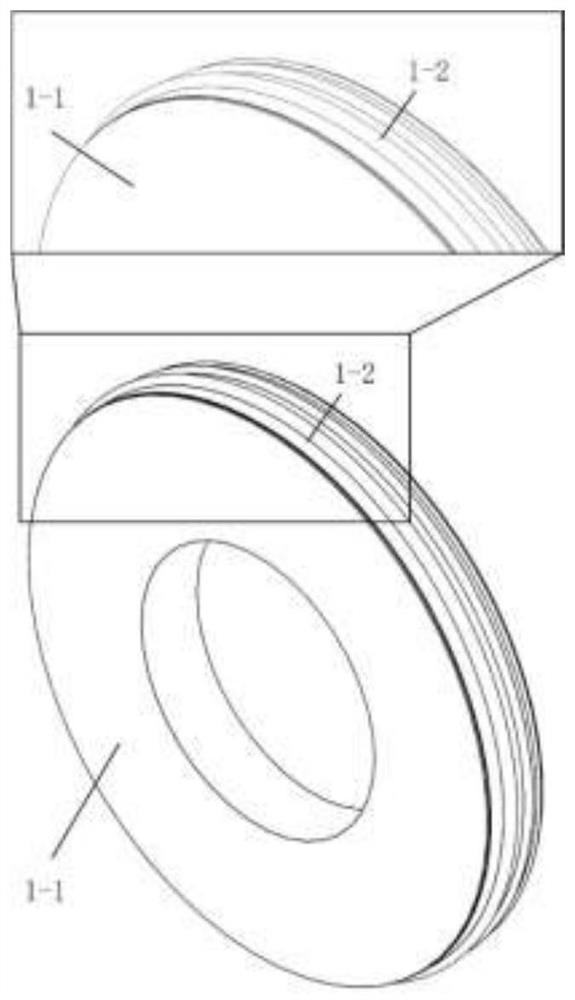

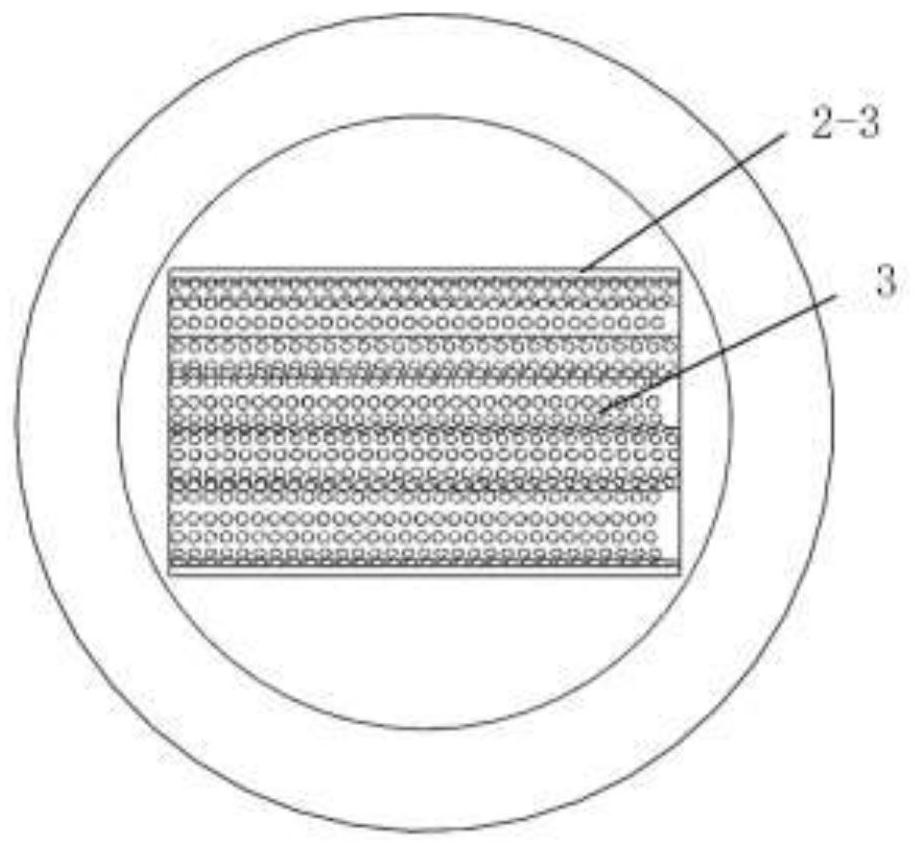

Embodiment 1

[0046] In this embodiment, the inner diameter of the grinding wheel is 127 mm, the outer diameter is 400 mm, and the width is 10 mm. The working surface of the grinding wheel is a plane, and the template on the ultrasonic head and the working surface of the grinding wheel are mutually concave and convex. The base body of the grinding wheel is precisely turned by a lathe to ensure that the roundness, runout of the base body and the flatness of the working surface of the grinding wheel are all within ±0.01mm. 0.2g / cm on the working surface of the grinding wheel 2 Spread a layer of copper-tin-titanium alloy solder evenly under high pressure, and use high-frequency induction brazing to heat the solder on the working surface to melt it, infiltrate it with the substrate, and spread it on the substrate to form a solder layer. Use the lathe to finish the grinding wheel substrate with the solder layer to further ensure the roundness, runout of the substrate and the flatness of the grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com