Chassis system and robot

A chassis and hub motor technology, applied in the field of robotics, can solve the problems of low ground adaptability, tire wear, motor power, and large consumption, and achieve the effects of not easy to slip, small turning radius, and reduced sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

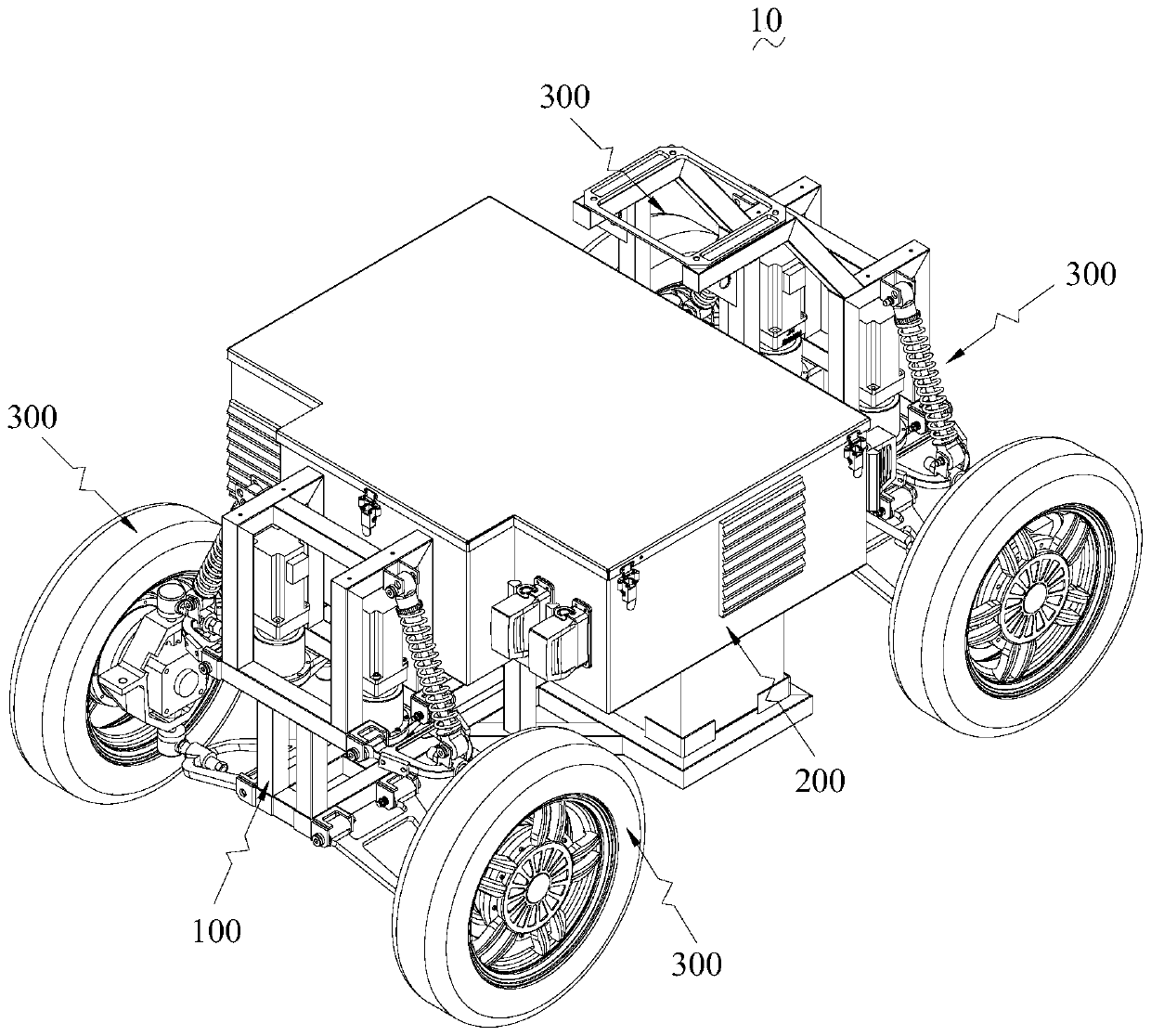

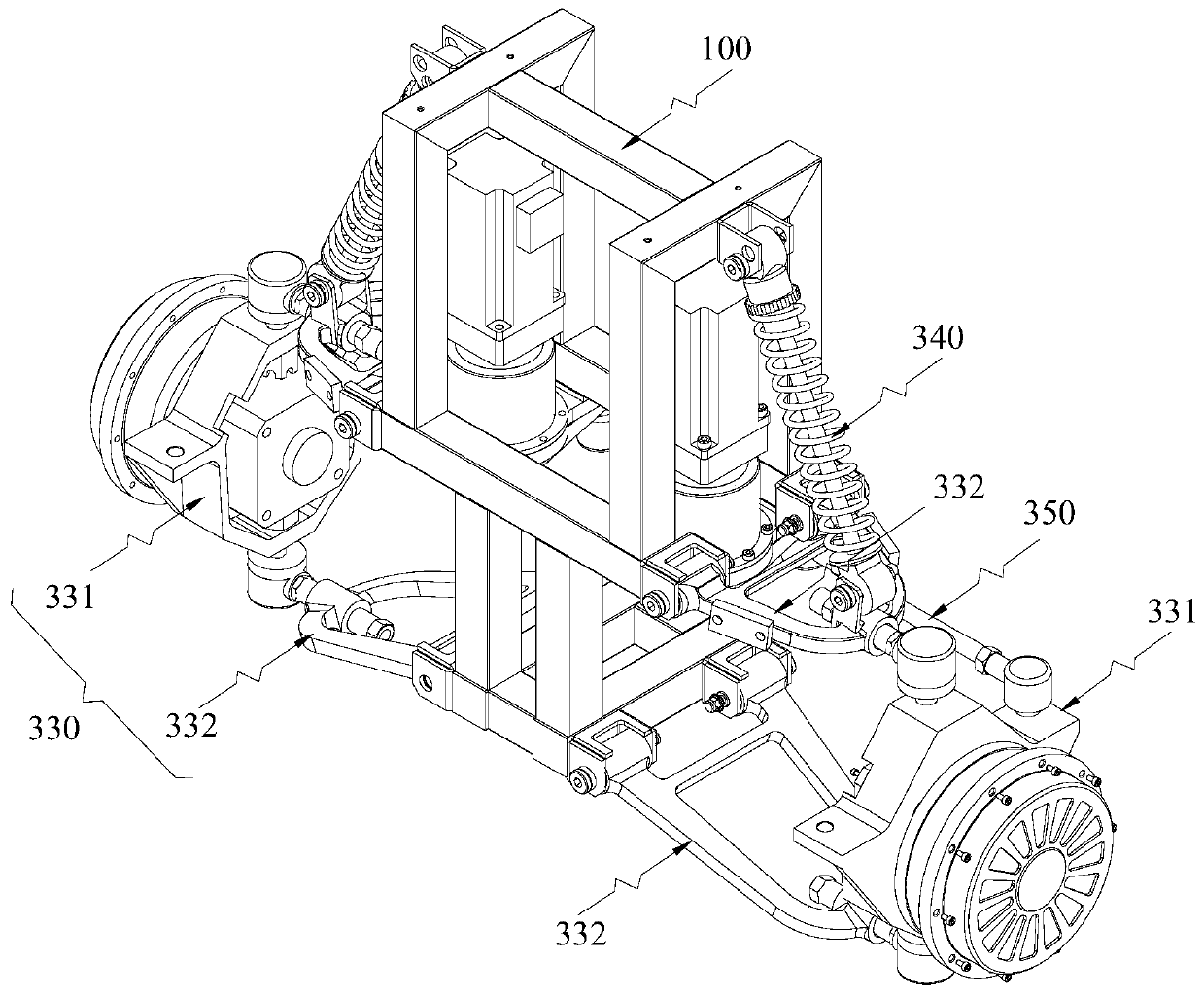

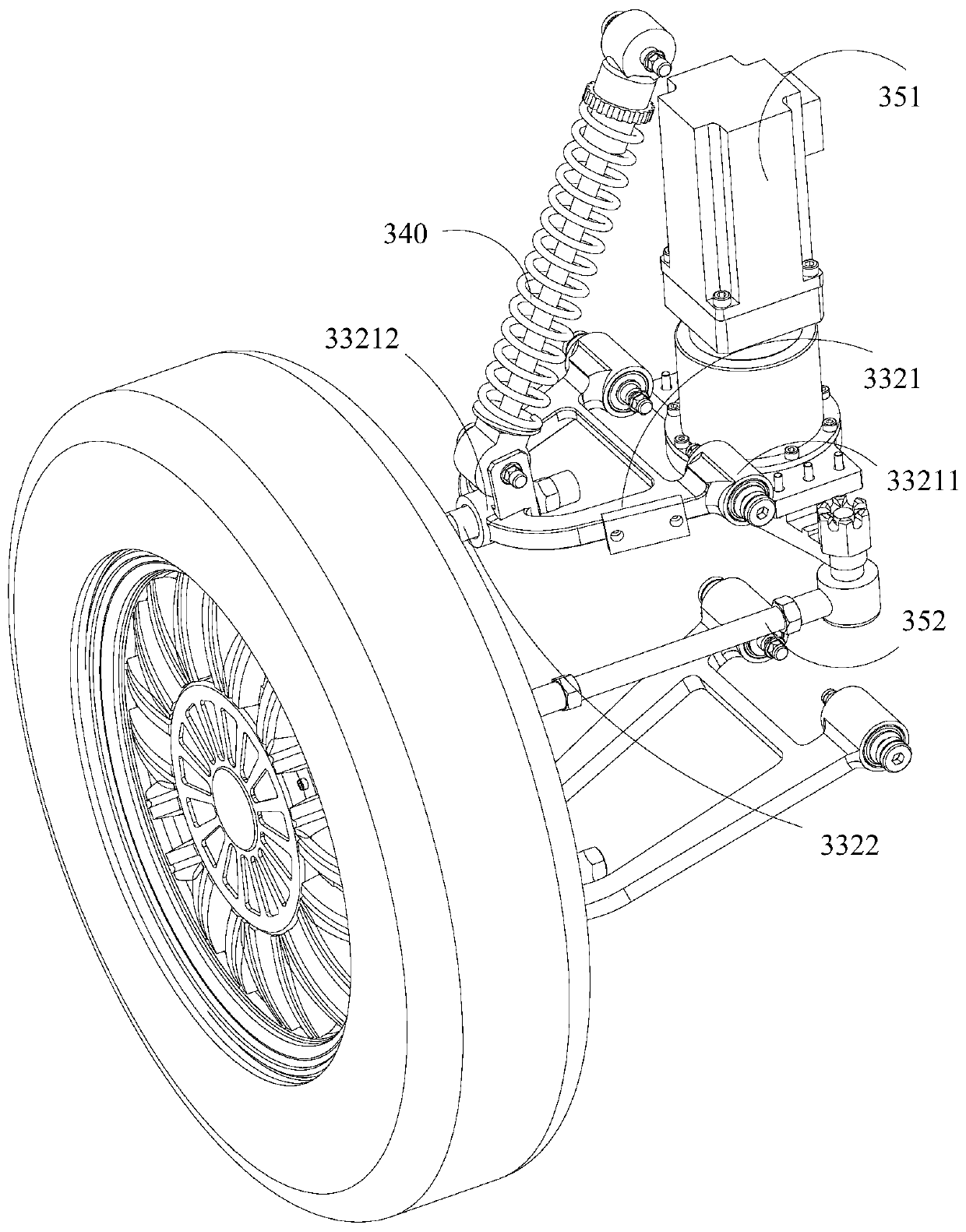

[0057] Furthermore, please also refer to figure 1 and Figure 5 , as a specific implementation of the chassis system 10 provided by the present invention, the electronic control module 200 includes a power supply 210 and a control unit 220 (not shown in the figure), the control unit 220 and the power supply 210, the hub The motor 320 is electrically connected to the steering assembly 350 . The power supply 210 is a power battery, and the control unit 220 includes an electric control box, a controller, a communication module, etc. located in the electric control box. Of course, the electric control box can also be used to place a robot communication module that cooperates with the chassis system 10. The rotation of the hub motor 320 can be controlled by the controller, and the rotation of the steering motor 351 of the steering assembly 350 can also be controlled by the controller, so as to realize steering control.

[0058] Furthermore, please also refer to figure 1 and Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com