Separated-type high-pile wharf wave dissipating structure and construction method thereof

A high-pile wharf and separate technology, applied in the field of port engineering, can solve the problems of not meeting the requirements of low water level wave protection, large sea areas, and difficult construction, and achieve reasonable force, small sea area, and simple construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

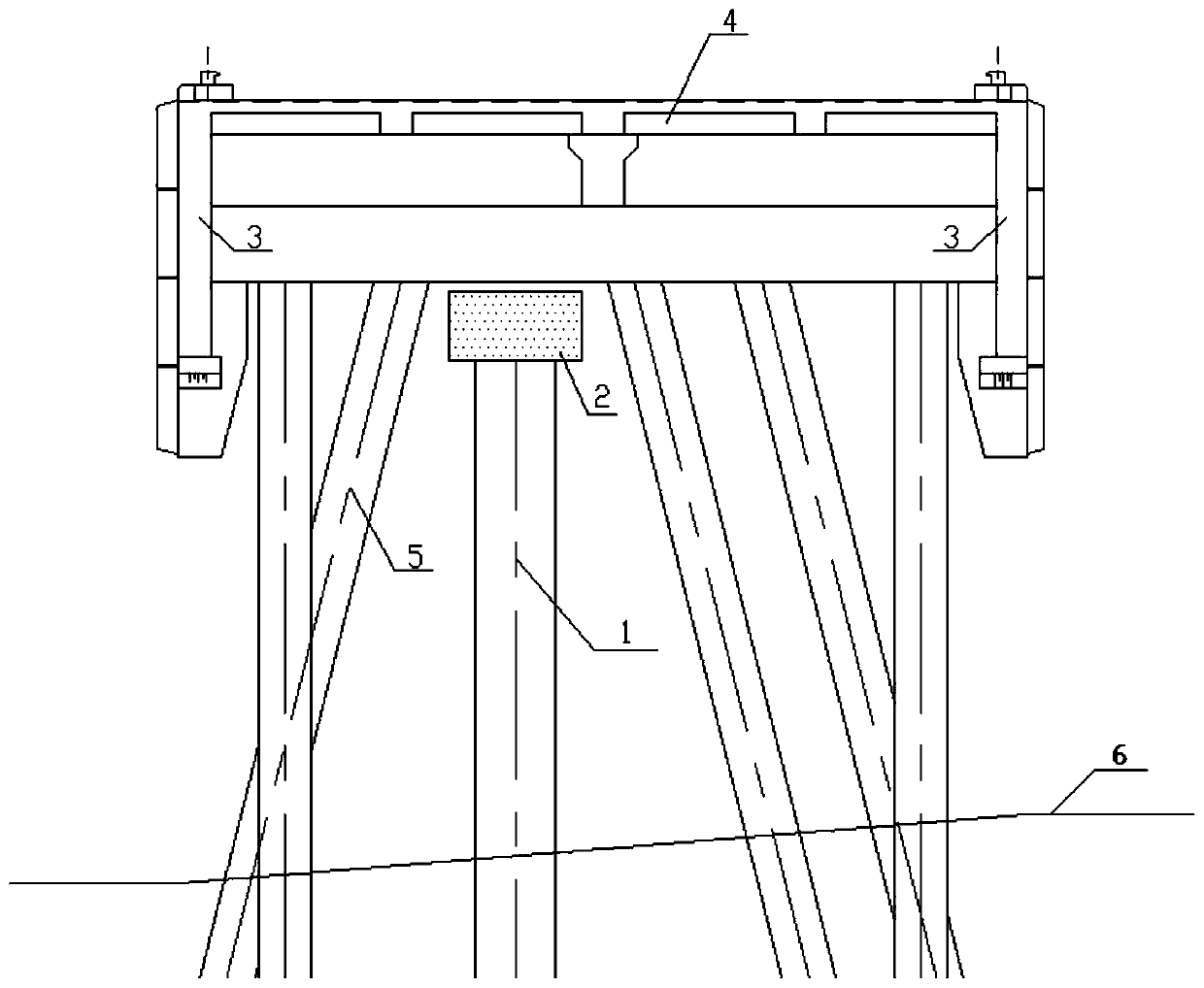

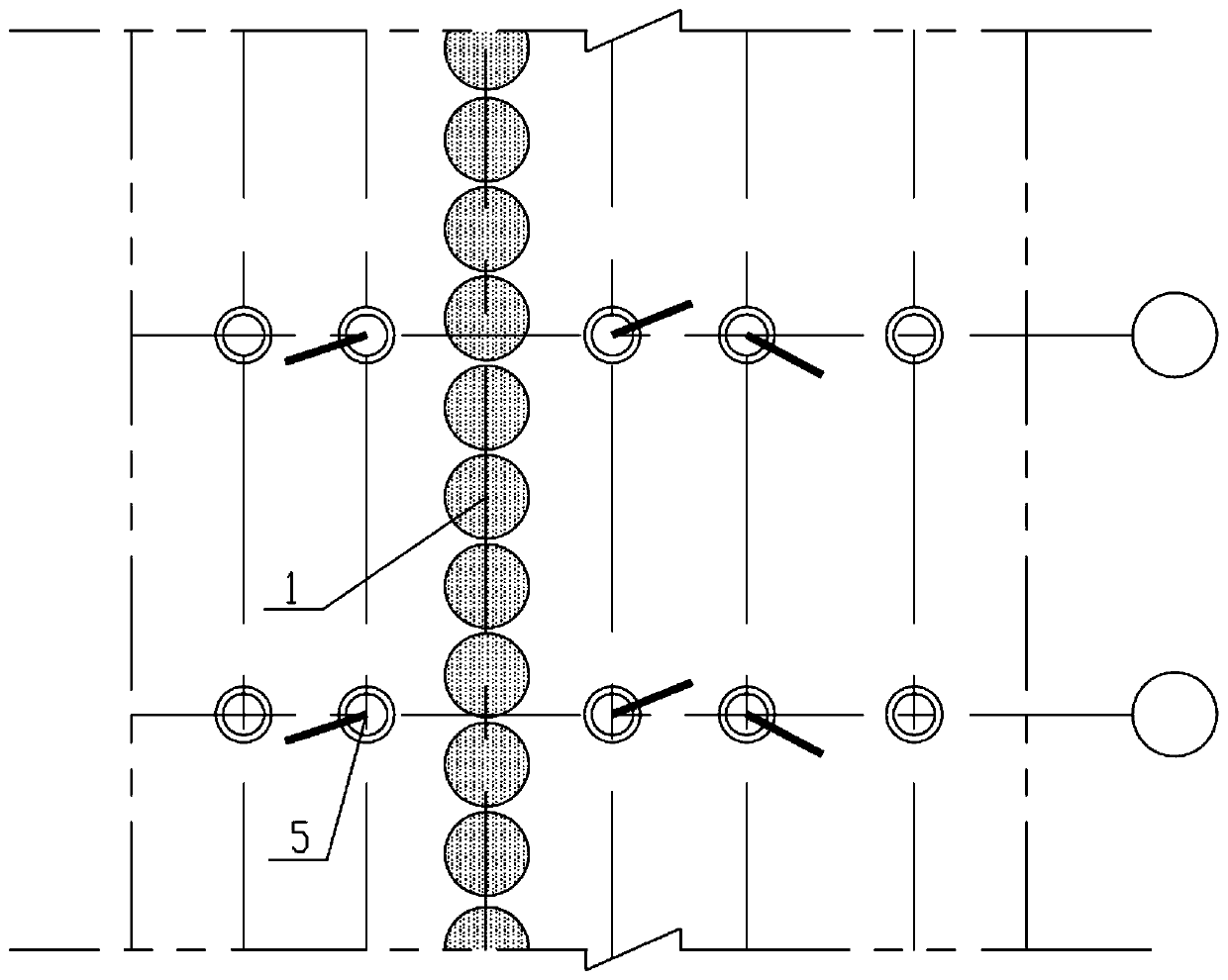

[0022] Such as figure 1 with figure 2 As shown, a separate high-piled wharf wave-dissipating structure includes close-packed piles 1, cast-in-place cap beams 2, wave-dissipating plates 3, high-pile wharf superstructure 4, and high-pile wharf pile foundations 5; the high-pile wharf piles The pile top of the foundation 5 is provided with a high-pile wharf superstructure 4, and a close-packed pile 1 is set under the high-pile wharf superstructure 4. The pile top of the close-pack pile 1 is provided with a cast-in-situ cap beam 2, and the pile The roof is connected as a whole by cast-in-place cap beams 2 to form a wave-retaining wall; the cast-in-place cap beam 2 is separated from the superstructure 4 of the high-piled wharf, and the close-packed piles 1 and the superstructure 4 of the high-pile wharf bear the wave force respectively, and are subjected to The force is clear, effectively increasing the safety of the main structure; both sides of the superstructure 4 of the high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com