Under-sill water delivery energy dissipation structure and construction method thereof

A construction method and energy dissipation technology, applied in the direction of ship lifting devices, ship locks, buildings, etc., can solve problems such as not being able to adapt to the construction requirements of ship locks, achieve the effects of solving energy and flow distribution, reducing construction difficulty, and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

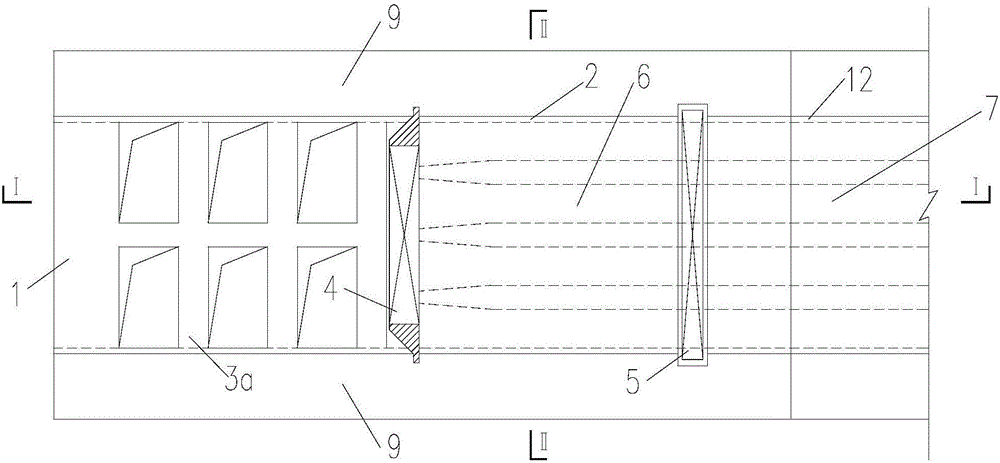

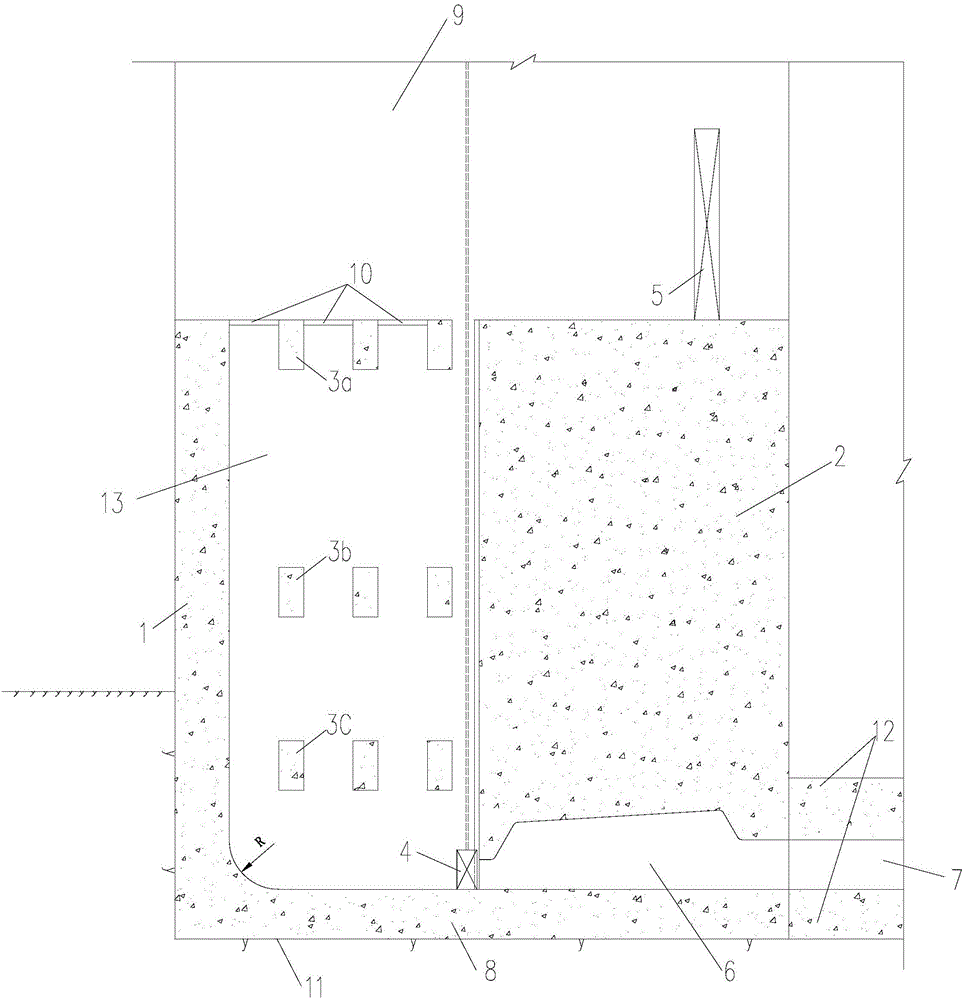

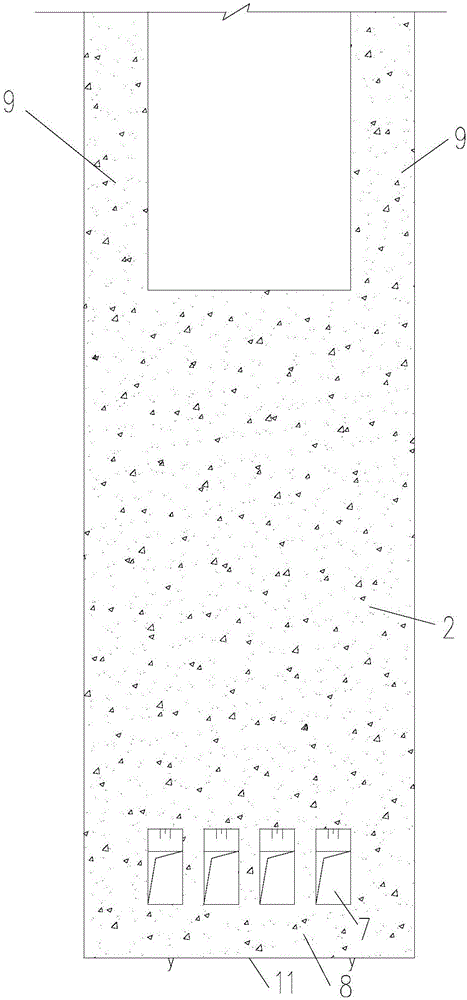

[0028] Such as Figure 1 ~ Figure 3 As shown, the present embodiment is a structure for conveying water under the sill and dissipating energy, using the space at the head of the ship lock to arrange the water retaining vertical plate 1, the energy dissipation grid, the head curtain wall 2, and the side wall 9 of the lock.

[0029] The gate head position is poured with gate head bottom plate 8, gate head curtain wall 2 is built on the gate head bottom plate 8, and gate side walls 9 are poured on both sides of gate head curtain wall 2. The water-retaining vertical plate 1, the water-retaining vertical plate 1 and the curtain wall 2 of the gate head are separated by a certain distance, so that a vertical water delivery shaft 13 is formed between the water-retaining vertical plate 1 and the curtain wall 2 of the gate head. Three layers of energy dissipation grids are provided at different elevations in the shaft 13 (the lower energy dissipation grid 3c, the middle energy dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com