Jetty type wharf with caisson structure, and construction method thereof

A construction method and a jetty technology, applied in the field of port and wharf engineering, can solve the problems of long construction period, lack of water and land transportation environment, large investment, etc., to reduce wave reflection and refraction, stable and firm wharf structure, and improve mooring conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

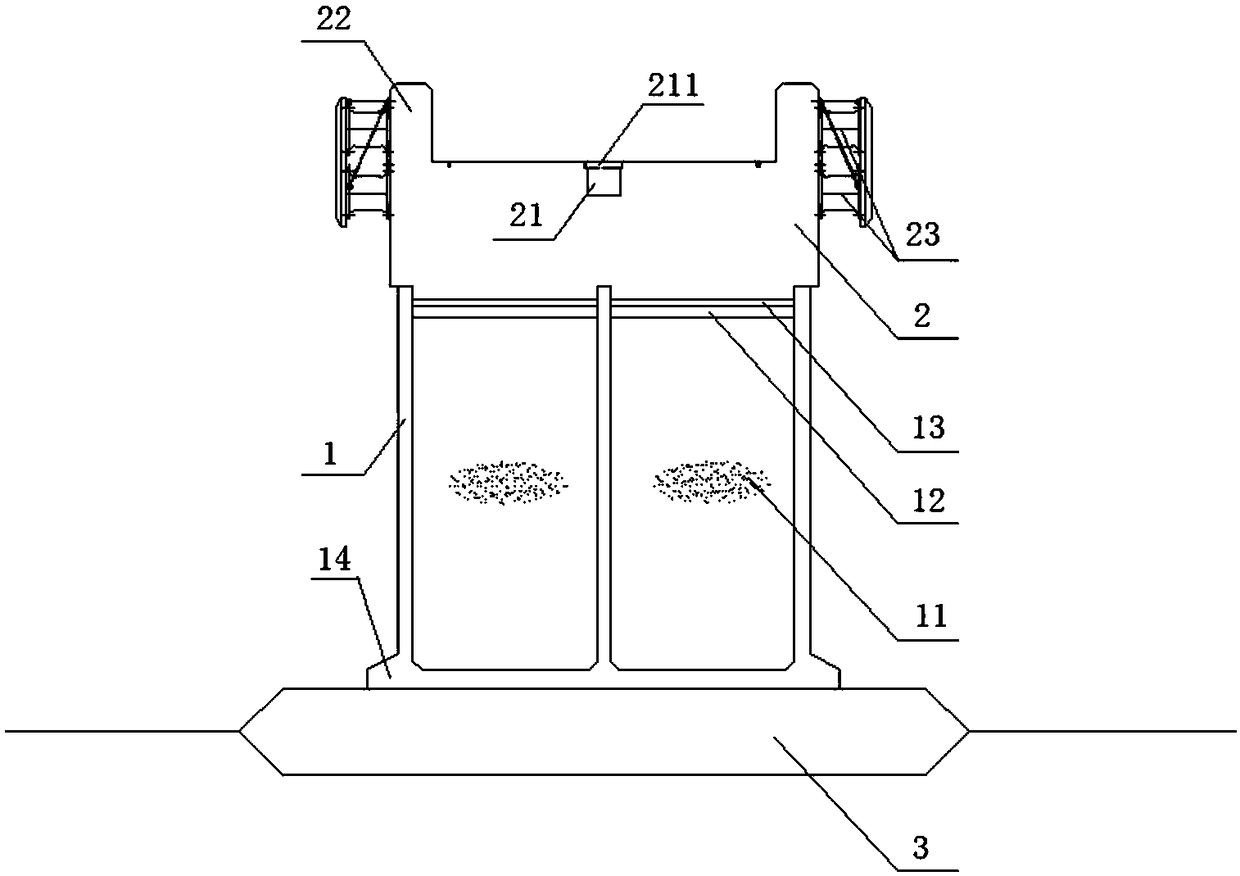

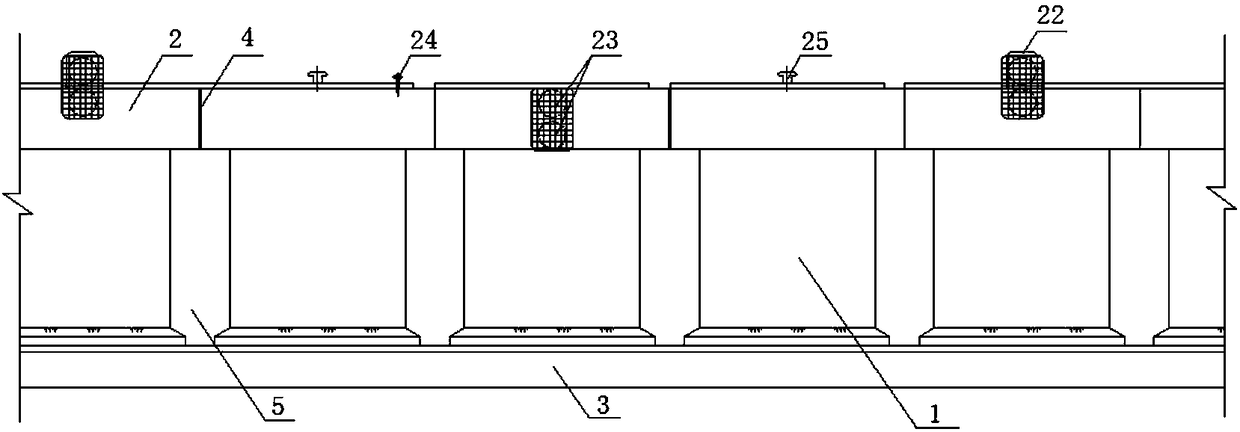

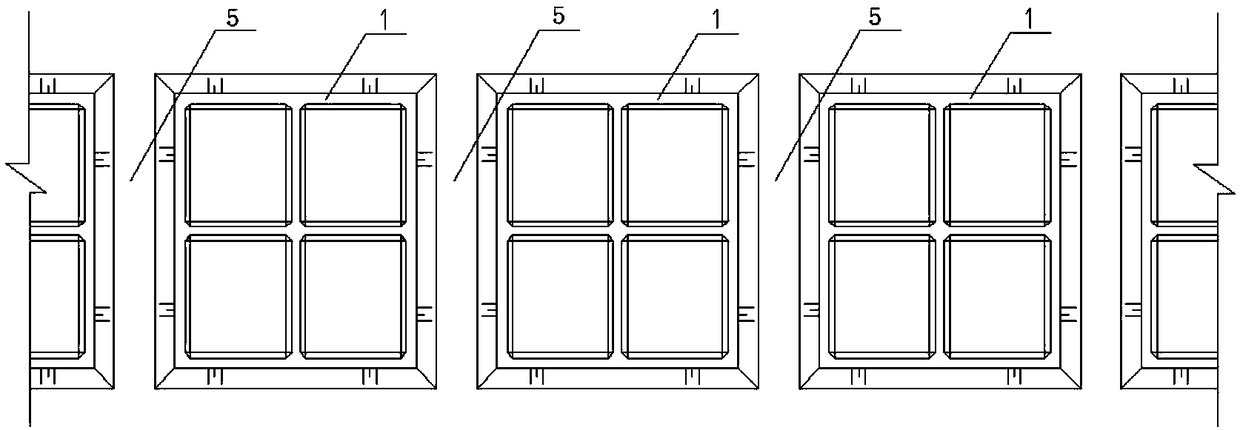

[0062] In this embodiment, a jetty wharf with a gravity caisson structure is provided, which includes a lower independent pier foundation structure and an upper continuous structure. The pier surface layer 2 is also provided with a structurally deformable connecting portion 4 . One end of the jetty jetty is perpendicular to the shoreline, and the other end extends to the sea side, including at least five gravity caissons 1, which are arranged in sequence; the gravity caissons 1 are arranged in an independent pier type , there is at least 1m of space between each gravity caisson 1 as the flow passage 5, and the distance between the caissons and the caissons in this embodiment is 3m.

[0063] The gravity caisson 1 includes at least two compartments vertically and horizontally, and the bottom of the four sides of the gravity caisson 1 protrudes from the front, rear, left and right, and is provided with toes 14. The gravity caisson 1 Backfill is arranged in the cells, and each ce...

Embodiment 2

[0067] In this embodiment, the foundation treatment of the foundation bed 3 includes the treatment of non-rock foundation and rock foundation. When it is a rock foundation, blast the foundation groove to the design elevation along the direction of the jetty wharf extending to the sea, and then use two pieces of stone or gravel to level the rock surface; Excavate the foundation trench in the direction of extension to the design depth and check the soil quality. To avoid silting after the verification is correct, block stones should be thrown and filled as soon as possible to form a foundation bed 3, and the foundation bed 3 is divided into a bright foundation bed, a dark foundation bed and a mixed foundation bed The type of riprap foundation bed can be determined according to water depth, terrain and foundation conditions.

[0068] The 3 stones of the foundation bed should use 10-100kg stones. For the thin foundation bed with a thickness of no more than 1m, smaller stones shoul...

Embodiment 3

[0070] In this embodiment, before the caisson 1 is installed, the foundation bed 3 and the caisson 1 should be inspected. The inspection of the foundation bed 3 requires divers to check the back-silting thickness of the foundation bed 3 and the gravity coefficient of the silt underwater, and the caisson 1 needs to check its The prefabrication date and concrete strength require that the strength must reach 100% of the design strength, and the foundation bed 3 and the caisson 1 can be installed only when they meet the relevant technical requirements.

[0071] The square barge upper caisson 1 is anchored and positioned near the installation site by being hauled by a tugboat. The anchoring needs to be carried out according to the position where the caisson 1 is to be installed. In this embodiment, the front and rear side anchors are casted first, forming a "eight" shape, and the middle is facing the required installation position of the caisson 1. A front middle anchor is thrown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com