A method and device for extracting removal function of magnetorheological polishing

A technology of magnetorheological polishing and extraction method, which is applied in the direction of complex mathematical operations, etc., can solve the problems of difficulty in accurately extracting effective data of magnetorheological polishing removal function, reducing the accuracy of magnetorheological processing, etc. easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] For example, the spot picking operation in this embodiment is performed on a domestic magnetorheological machine tool, and the spot picking substrate is made of fused silica, a circular substrate with a diameter of 50 mm and a thickness of 5 mm.

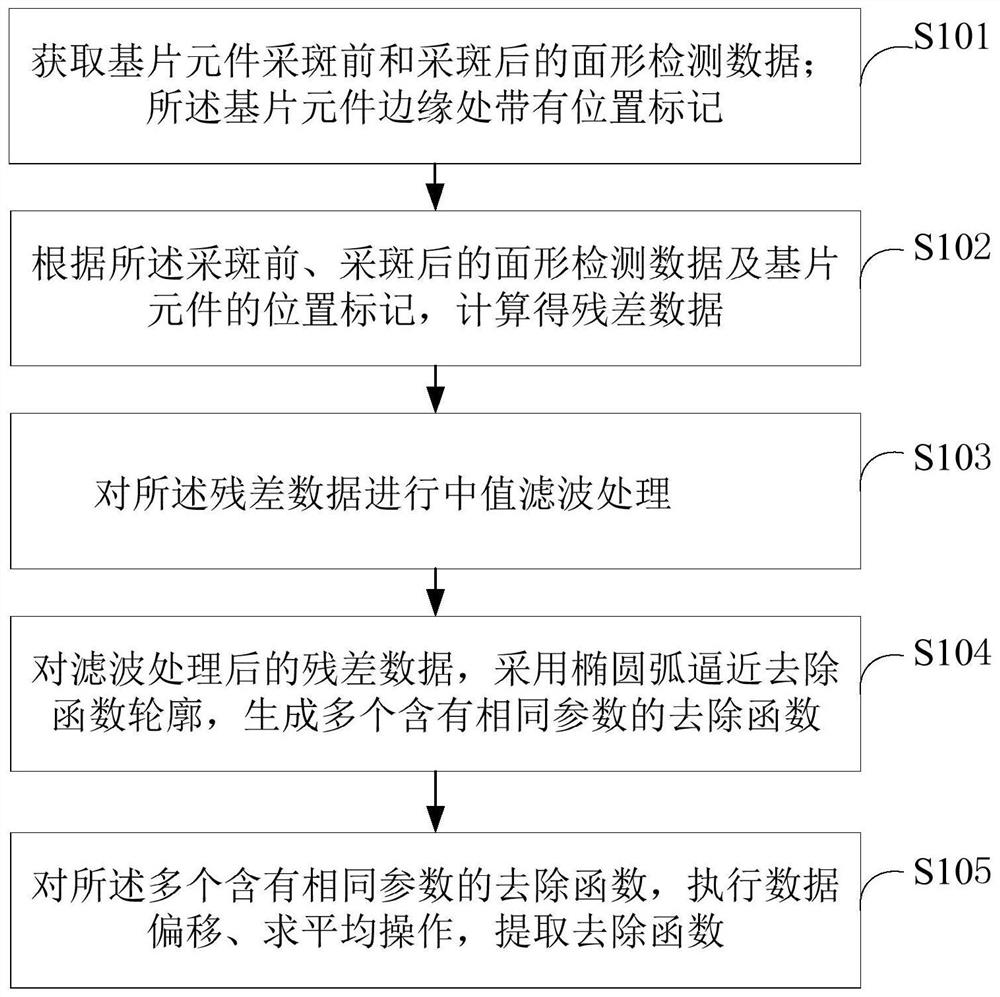

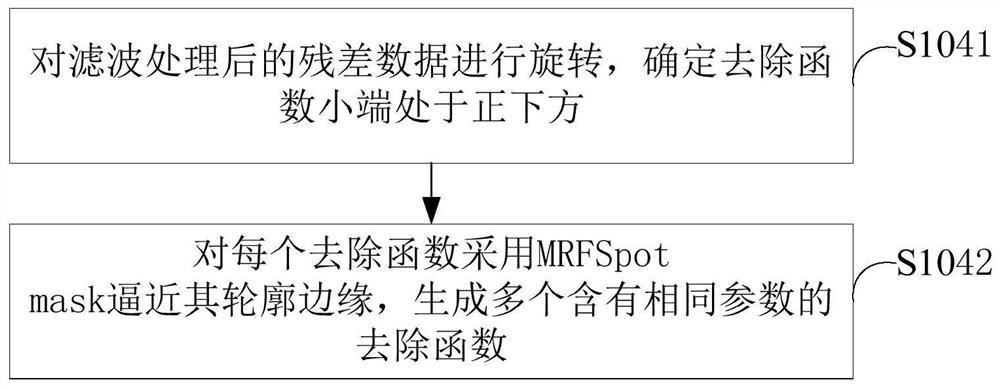

[0103] Specifically, as Image 6 As shown, the extraction of the magnetorheological removal function is performed by the following method steps.

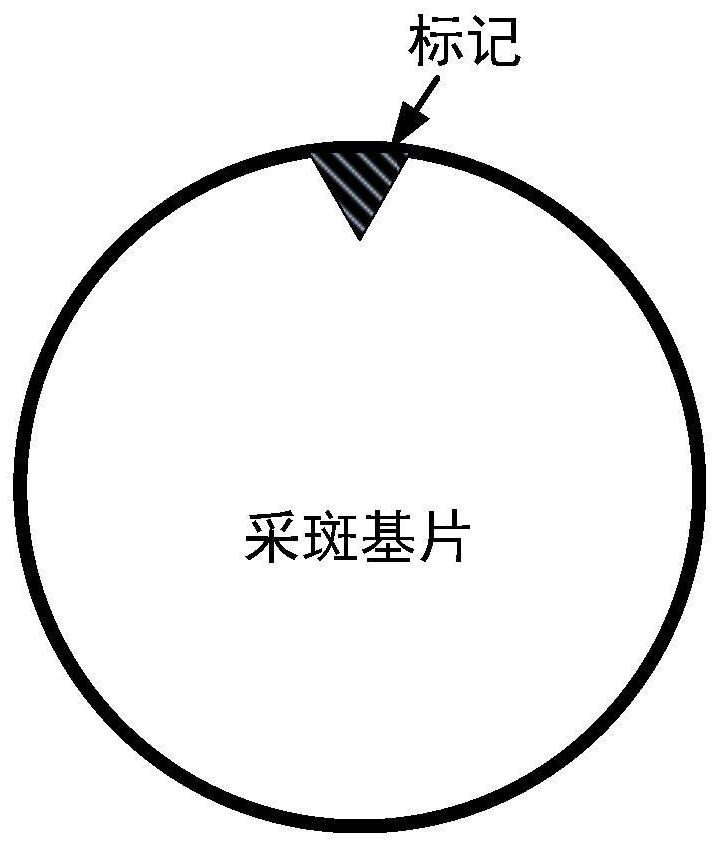

[0104] 1. Select the spot-picking substrate element, the substrate surface is required to be flat, and a fused silica substrate with PV=0.5λ is selected for spot-picking. First, wipe the surface of the element clean, and use scissors to cut out the label paper with a side length of about 5mm , stick it on the edge of the substrate element;

[0105] 2. Use an interferometer to measure the surface shape of the substrate element, save the detection data, name it start, the initial PV of the substrate is 0.486λ, and the positioning marks are clearly visible, such as Figure 7 shown;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com