Decolorization of concentrated rhamnolipid composition

A technology of rhamnolipid and composition, which is applied in the field of decolorization of concentrated rhamnolipid composition, and can solve the problem of high operating cost of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

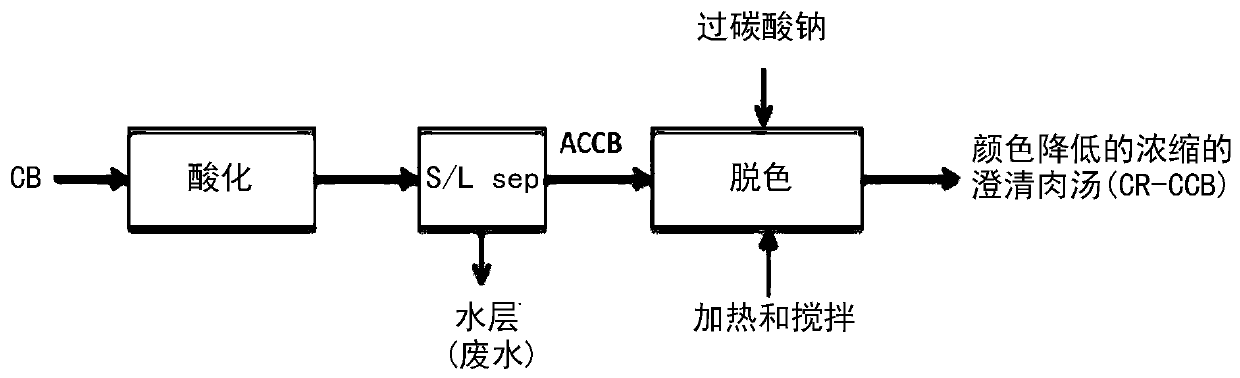

[0032] Example 1 : Decolorization of Concentrated Clarified Broth (ACCB) in acid form with addition of 0.75-3% w / w Equivalent Hydrogen Peroxide Concentration (EHPC) of Sodium Percarbonate at 60°C

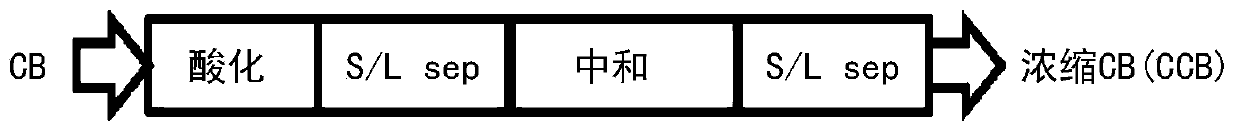

[0033] The starting material for the process is acid form concentrated clarified broth (ACCB) obtained by precipitating rhamnolipids from clarified broth (CB) at pH 2.1 prior to the neutralization step as described in US20160272667 .

[0034] The pH of the starting material ACCB is about 2.1. Change the chemical formula to Na 2 CO 3 1.5H 2 o 2 Sodium percarbonate was added to the ACCB at 0.75-3% w / w equivalent hydrogen peroxide concentration (EHPC). Use MaxQ TM An 8000 Stackable Orbital Shaker (ThermoScientific) heated the samples with stirring at 250 rpm at 60°C to ensure uniformity of stirring speed and temperature across all samples.

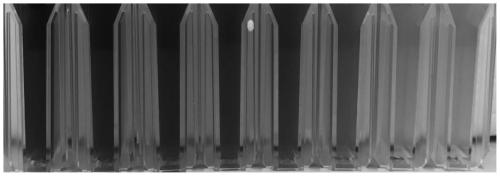

[0035] The reduction in color of the sample with addition of sodium percarbonate is shown in image 3 and 4 .

[0036] In samples where ...

Embodiment 2

[0041] Example 2: Decolorization of concentrated clarified broth (ACCB) in acid form with addition of sodium percarbonate at 1% - 2.5% w / w equivalent hydrogen peroxide concentration (EHPC) at 45°C

[0042] The starting material for this process is concentrated clarified broth (ACCB) described in Example 1 in acid form. Sodium percarbonate was added to the starting material ACCB at 1%, 1.5%, 2% and 2.5% w / w equivalent hydrogen peroxide concentration (EHPC). Sodium hydroxide (NaOH) was also added to the sodium percarbonate spiked samples in an amount less than 2.5% EHPC to bring the pH to ~7.

[0043] The sample was then heated at 45 °C in an unbaffled flask while using the MaxQ TM An 8000 stackable orbital shaker (Thermo Scientific) was stirred at 350 rpm to ensure consistency of stirring speed and temperature for all samples. with GENESYS TM A 20 Visible Spectrophotometer (Thermo Scientific) quantifies the darkness of the samples to measure the optical density (OD) of the s...

Embodiment 3

[0044] Example 3: Addition of Sodium Percarbonate, Decolorization and Wastewater Quality Enhancement of Aqueous Waste Stream of Non-Organic Solvent Rhamnolipid Concentration Process by Acid Precipitation as Described in US20160272667

[0045] The aqueous (aqueous) layer from the acid precipitation step of the clarification broth (CB) used to obtain the concentrated rhamnolipid product described in Examples 2-6 of US20160272667 is considered to be waste water from the process, which is the present Starting material for the examples. Sodium percarbonate was added to the acid wastewater stream at 60°C at 0.25% and 0.5% EHPC. After 1 hour of gentle stirring at 60°C, the sample was removed from the heat and allowed to cool to room temperature within 1-2 hours. The samples were then subjected to optical density measurements and analysis for biological oxygen demand (BOD) and total suspended solids (TSS). BOD

[0046] with GENESYS TM The optical density (OD) of the samples was me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com