Self-decaying mlcc array

A pulse and trace technology, which is applied to fixed capacitance components, fixed capacitors, frequency response correction, etc., can solve problems such as noise generation, microphone noise not eliminated, microphone noise addition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

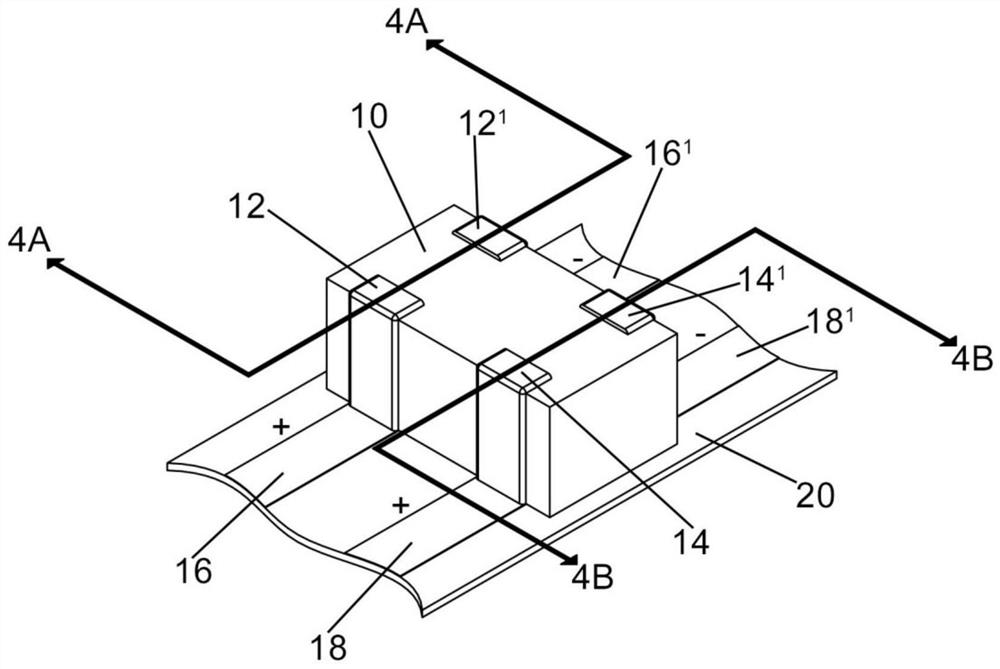

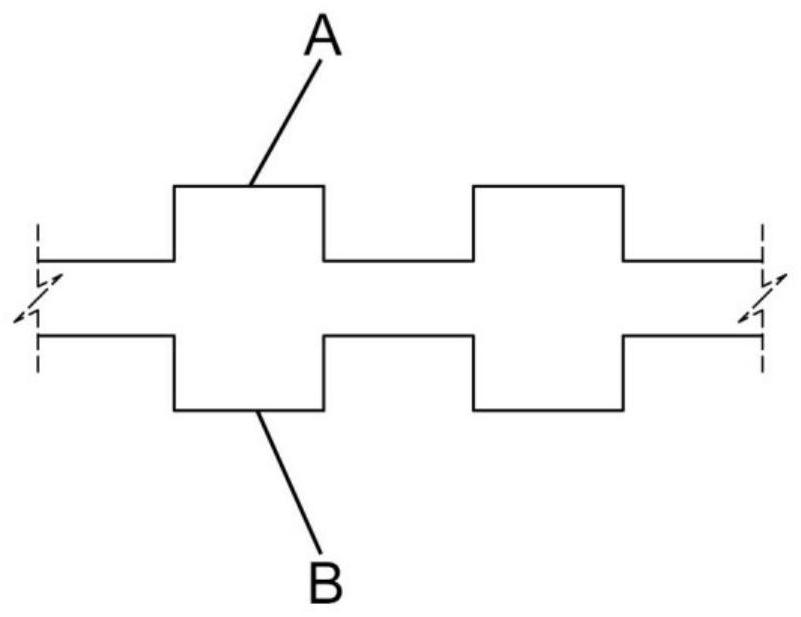

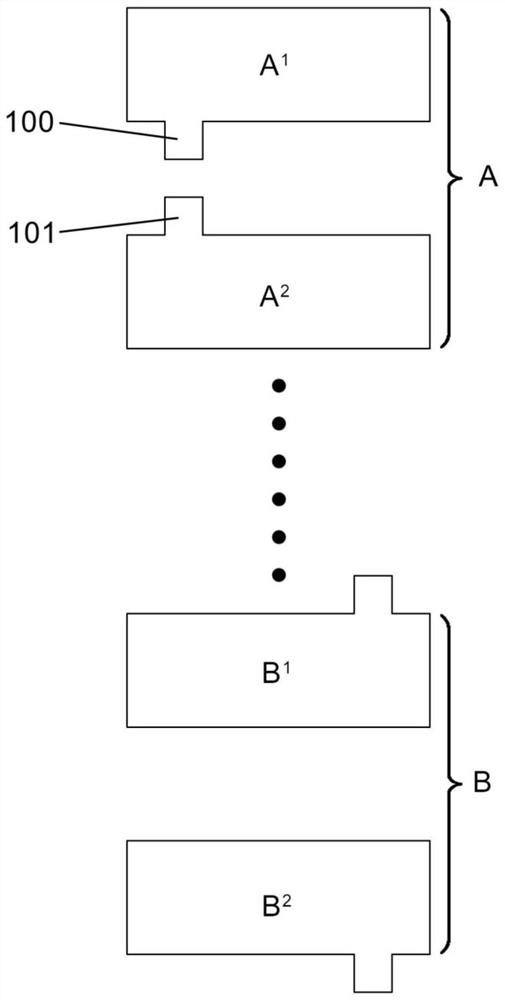

[0029] The present invention relates to an improved array of MLCCs, and an electronic device comprising the array, wherein at least one MLCC is mounted to a substrate, and the MLCC has self-attenuating characteristics for microphone noise, wherein the MLCC has a first electrical phase A first capacitive electrode and a second capacitive electrode in a second electrical phase, wherein the first phase is sufficiently out of phase with the second phase to suppress and preferably cancel microphone noise through noise cancelation.

[0030] It is known in the art that MLCCs include capacitive couplings comprising a plurality of conductive layers with a dielectric between the plurality of conductive layers, wherein alternating layers are terminated to external terminations of opposite polarity. In one embodiment of the present invention, a self-attenuating MLCC includes a first capacitive couple and a second capacitive couple, wherein the first capacitive couple and the second capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com