Portable rice branch removing machine

A portable, rice technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of inconvenience to carry, test errors, easy to mix, etc., to achieve convenient maintenance and maintenance, reduce labor intensity, easy installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

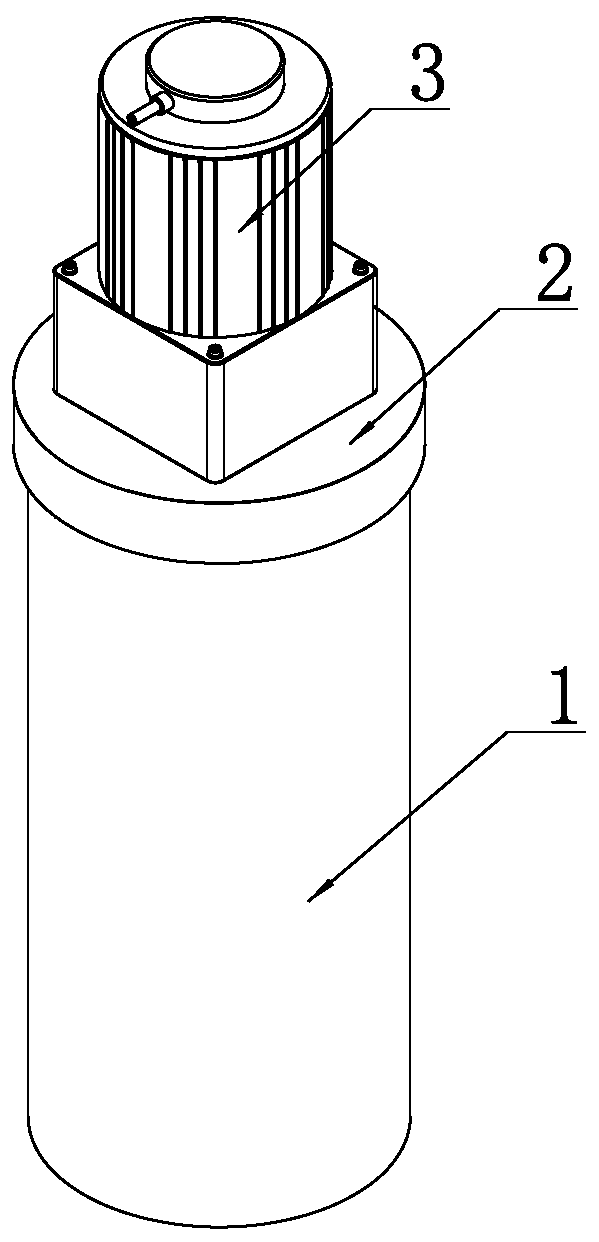

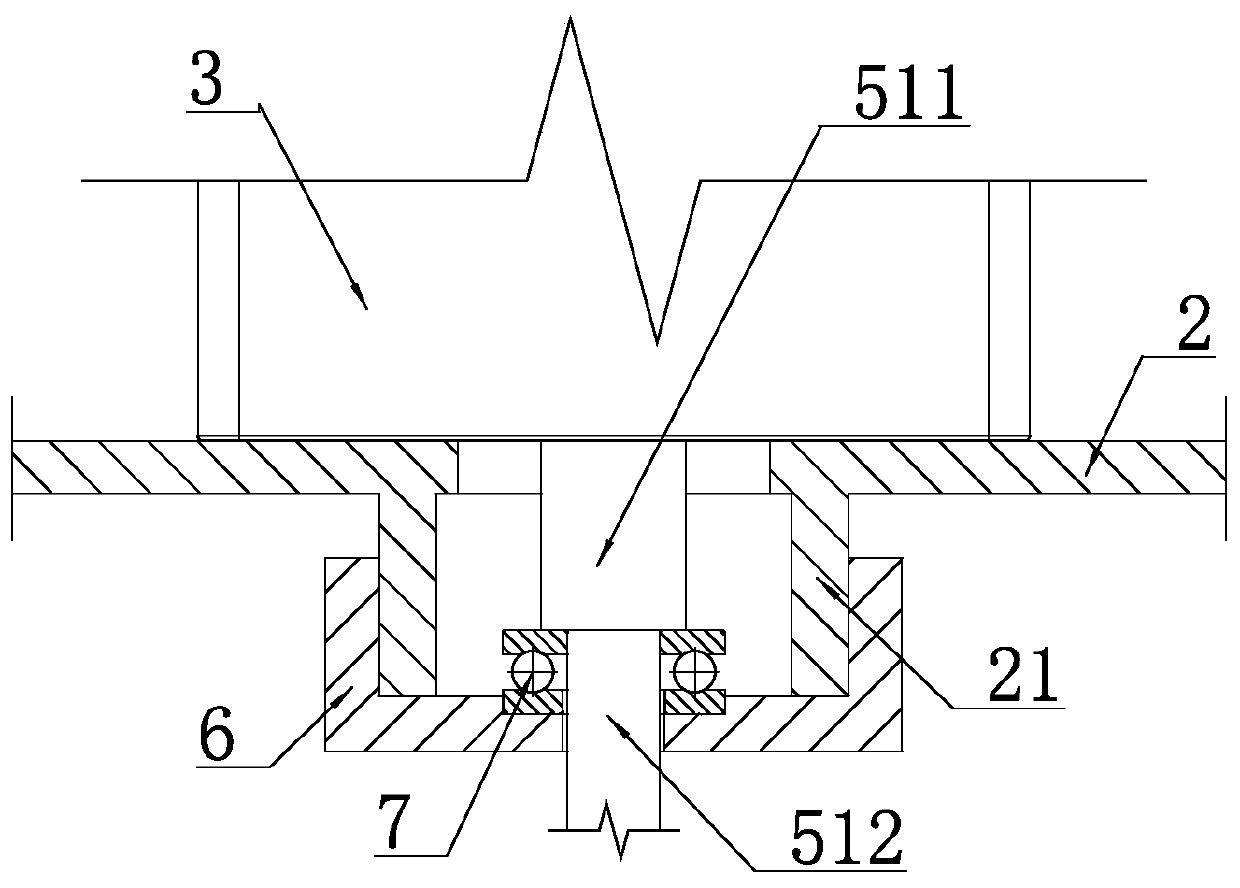

[0039] Such as figure 1 As shown, a portable rice branch remover includes a mixing bucket 1, and the mixing bucket 1 is a barrel with a cylindrical cross section with an open upper end and a closed lower end. The upper end of the mixing bucket 1 is provided with an upper cover 2 for closing the mixing bucket 1 .

[0040] The mixing barrel 1 is provided with a stirring assembly for stirring the rice, and the stirring assembly is rotatably connected with the upper cover 2, and the upper cover 2 is provided with a device for driving the stirring assembly to rotate. The motor 3.

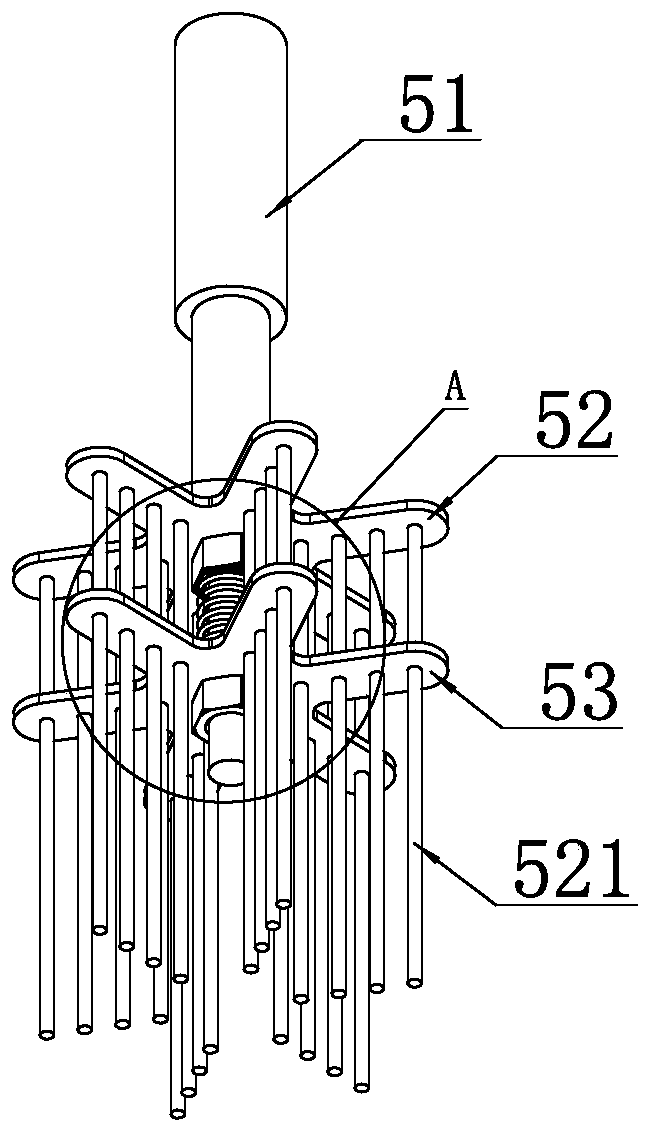

[0041] Such as image 3 , Figure 4 with Figure 5 As shown, the stirring assembly includes a stirring shaft 51, and the stirring shaft 51 sequentially includes a large shaft section 511, a small shaft section 512 and a screw 513 from top to bottom, and the large shaft section 511, the small shaft section 512 And the diameter of screw rod 513 decreases successively. A flat plate 52 and a stiffness ...

Embodiment 2

[0048] For the convenience of description, the coordinate system is defined for the second embodiment as Figure 8 shown.

[0049] In the past, after removing the branches by hand rubbing, it was necessary to remove the branches that had fallen off the rice by cleaning. Since the removal operation of the branches in the first step cannot be completely thorough, this process needs to be repeated until all the branches in the rice are removed, the operation time is long, the labor load is large, and the efficiency is low.

[0050] For this, as Image 6 with Figure 8 As shown, the shown mixing bucket 1 includes a first mixing bucket 11, a second mixing bucket 12 and a connecting portion 13 arranged between the first mixing bucket 11 and the second mixing bucket 12, and the first The mixing bucket 11 communicates with the second mixing bucket 12 through a connecting portion 13 . Both the upper ends of the first mixing bucket 11 and the second mixing bucket 12 are provided wit...

Embodiment 3

[0059] Only the first mixing bucket 11 is provided with a stirring assembly, correspondingly, only the upper cover 2 of the first mixing bucket 11 is provided with a motor 3, and the rest of the structure is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com