Cultivation method for improving tobacco light energy utilization rate in Changsha tobacco area

A cultivation method and utilization rate technology, applied in the field of cultivation to improve the light energy utilization rate of tobacco in Changsha Tobacco Area, can solve the problems of reduced production capacity, lack of tobacco growth and development, and product quality, and achieve optimal quality, achieving moderate growth and average weight per kilogram The effect of increasing the price and per mu output value and improving the utilization rate of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

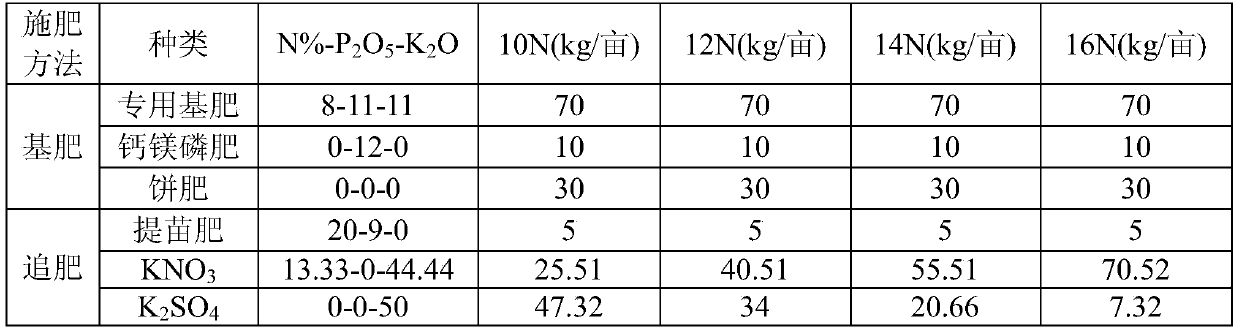

[0031] (1) Tobacco field preparation: After loosening the soil in the tobacco field, apply cake fertilizer 30kg / mu, special base fertilizer 70kg / mu, and calcium magnesium phosphate fertilizer 10kg / mu.

[0032] (2) Ridging: ridge bottom width 80cm, ridge top width 25cm, ridge height 30cm, ridge distance 120cm, mechanical ditching is used on the smoke ridge, the ditch depth is 15cm, the width of the upper mouth of the ditch is 20cm, and the width of the ditch bottom is 10cm. trapezoidal.

[0033] (3) Planting: the transplanting distance of tobacco seedlings is 120 cm, the planting depth is 12 cm, and the planting density of tobacco seedlings is 1100 plants / mu.

[0034] (4) Fertilization: after planting, by applying KNO 3 Control the level of nitrogen fertilizer with seedling fertilizer, and the nitrogen application rate is 10kg / mu.

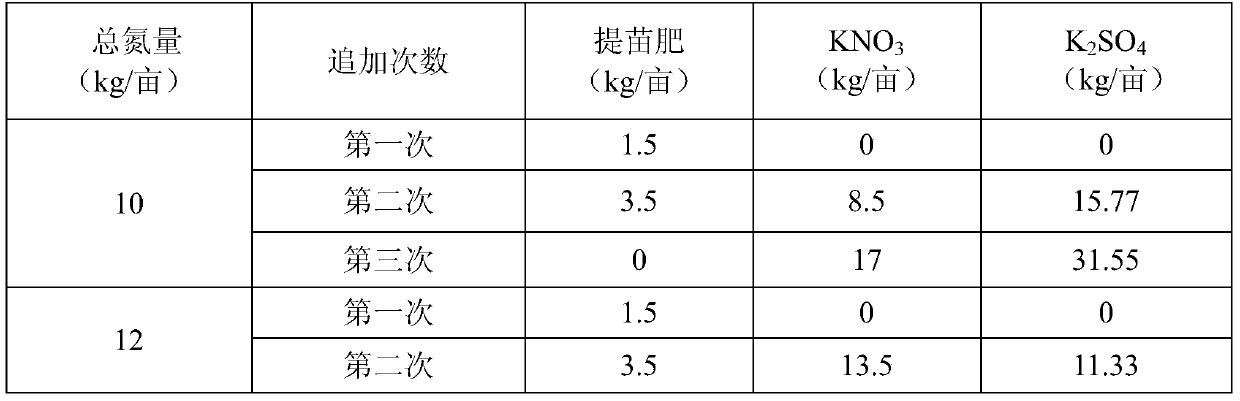

[0035] (5) Topdressing: Topdressing three times in total, the first topdressing was the seedling fertilizer, and the second topdressing was the s...

Embodiment 2

[0037] (1) Tobacco field preparation: After loosening the soil in the tobacco field, apply cake fertilizer 30kg / mu, special base fertilizer 70kg / mu, and calcium magnesium phosphate fertilizer 10kg / mu.

[0038] (2) Ridging: ridge bottom width 80cm, ridge top width 25cm, ridge height 30cm, ridge distance 120cm, mechanical ditching is used on the smoke ridge, the ditch depth is 15cm, the width of the upper mouth of the ditch is 20cm, and the width of the ditch bottom is 10cm. trapezoidal.

[0039] (3) Colonization: the tobacco seedlings are transplanted with a row spacing of 120 cm, a planting depth of 12 cm, and a planting density of tobacco seedlings of 1100 plants / mu.

[0040] (4) Fertilization: after planting, by applying KNO 3 And raise the seedling fertilizer to control the level of nitrogen fertilizer, the amount of nitrogen application is 12kg / mu.

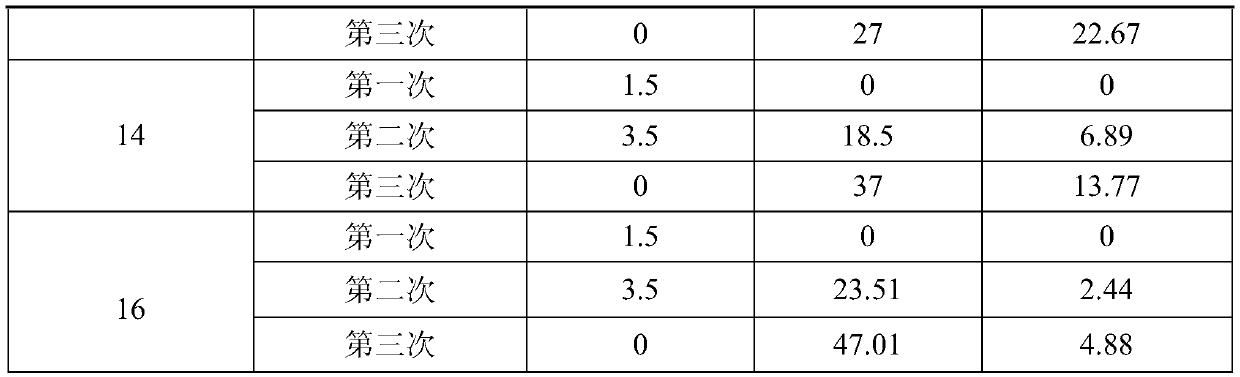

[0041] (5) Topdressing: Topdressing three times in total, the first topdressing was the seedling fertilizer, and the secon...

Embodiment 3

[0043] (1) Tobacco field preparation: After loosening the soil in the tobacco field, apply cake fertilizer 30kg / mu, special base fertilizer 70kg / mu, and calcium magnesium phosphate fertilizer 10kg / mu.

[0044] (2) Ridging: ridge bottom width 80cm, ridge top width 25cm, ridge height 30cm, ridge distance 120cm, mechanical ditching is used on the smoke ridge, the ditch depth is 15cm, the width of the upper mouth of the ditch is 20cm, and the width of the ditch bottom is 10cm. trapezoidal.

[0045] (3) Colonization: the tobacco seedlings are transplanted with a row spacing of 120 cm, a planting depth of 12 cm, and a planting density of tobacco seedlings of 1100 plants / mu.

[0046](4) Fertilization: after planting, by applying KNO 3 And raise the seedling fertilizer to control the level of nitrogen fertilizer, the amount of nitrogen application is 14kg / mu.

[0047] (5) Topdressing: Topdressing three times in total, the first topdressing was the seedling fertilizer, and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com