Fruit puree or ice cream making device and multifunctional juicer

A technology for making a device and ice cream, which is applied to household machinery, household appliances, applications, etc. for filtering food, can solve the problems of insufficient strength, large space occupation, and difficulty in installation, so as to avoid excessive water loss, small space occupation, and easy installation. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

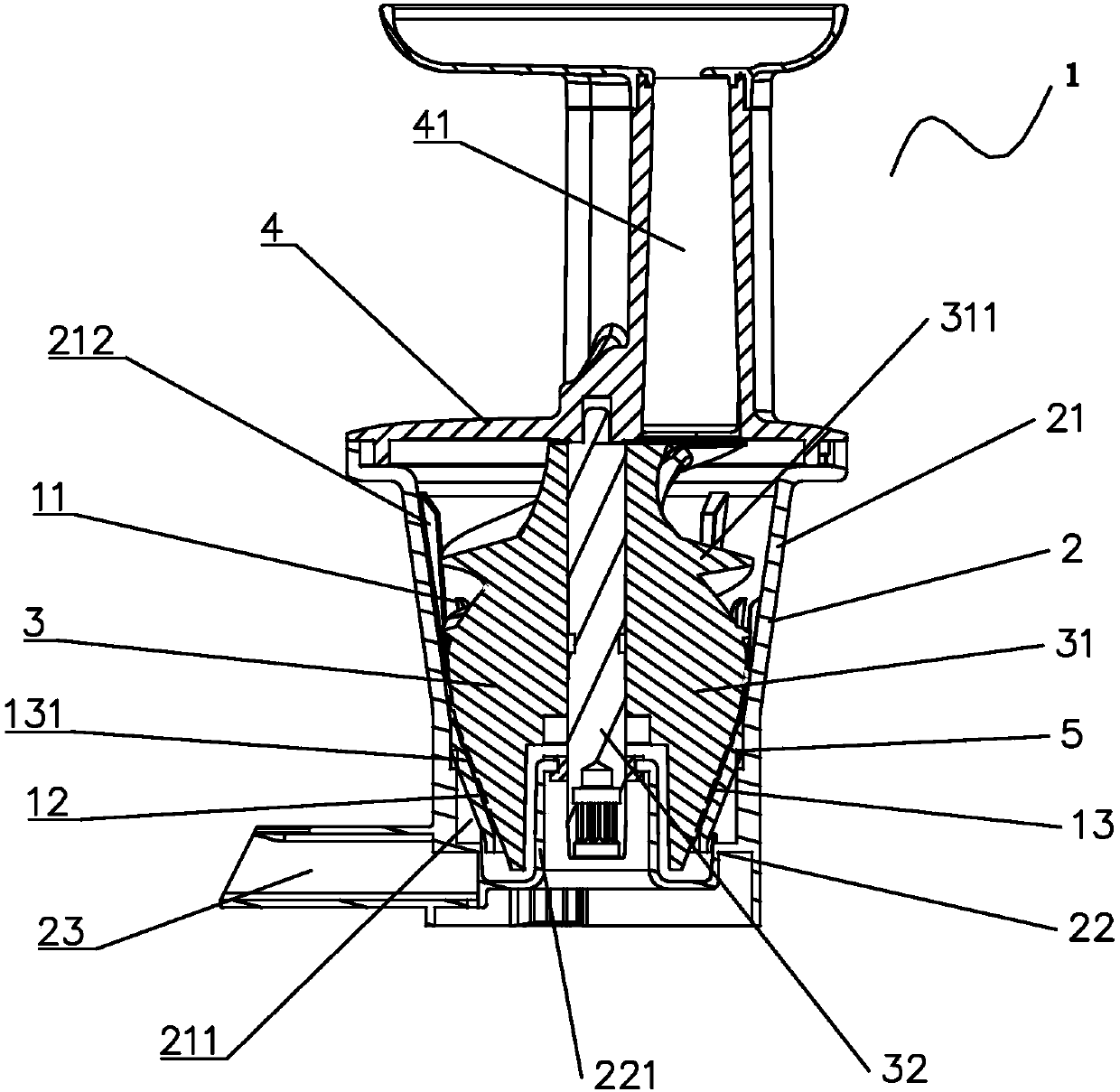

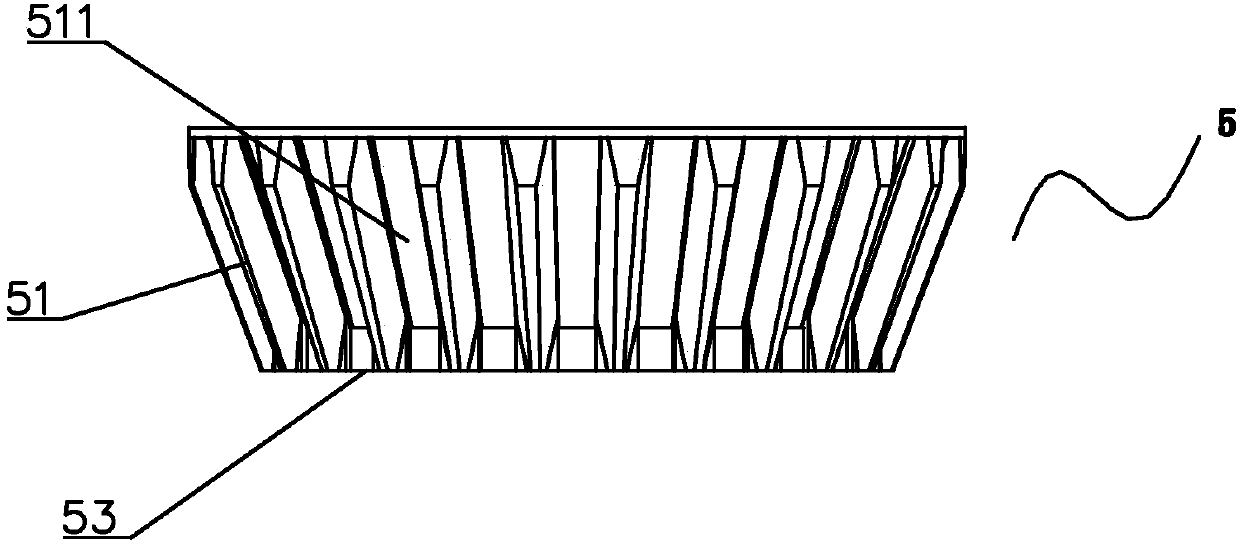

[0049] Such as figure 1 and figure 2 As shown, a fruit puree or ice cream making device 1 includes a squeeze chamber 2, a screw 3 longitudinally arranged in the squeeze chamber, and a loamer 4 covering the top of the squeeze chamber, the loamer is provided with a feed port 41, Described squeeze chamber comprises squeeze chamber sidewall 21 and squeeze chamber bottom wall 22, and described squeeze chamber bottom wall 22 is provided with waterproof cylinder 221, and screw rod comprises screw rod body 31 and screw rod shaft 32, and screw rod body is provided with helix 311, also Including a fruit puree 5, the fruit puree is sleeved on the outside of the screw, the fruit puree includes an annular side wall 51, the annular side wall is provided with a plurality of longitudinally arranged strip-shaped holes 511, and the inner wall of the pressing chamber is provided with strip-shaped holes. The protrusions 211 that are inserted into the holes extend downward from the side wall 21 ...

Embodiment 2

[0054] The difference between this embodiment and the first embodiment lies in that the structure of the fruit puree device is different.

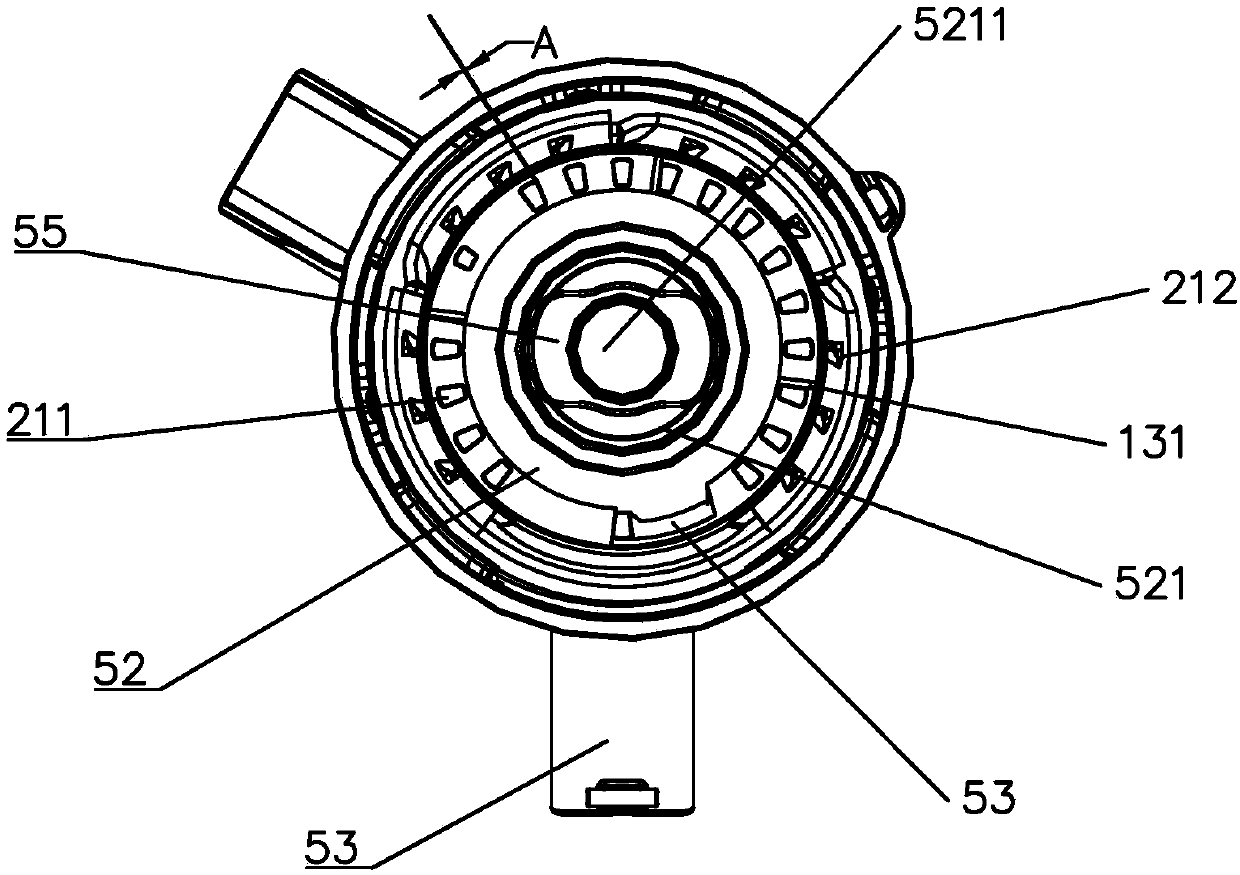

[0055] Such as image 3 As shown, in this embodiment, the fruit puree 5 also includes a bottom wall 52 connected to the annular side wall 51, and the center of the bottom wall 52 partially protrudes upwards to form a waterproof boss 521, specifically, the waterproof boss 521 It is hollow cylindrical, and the height of the waterproof boss 521 is higher than that of the annular side wall 51 , and the side wall of the waterproof boss forms a draft angle for easy demoulding. The bottom wall 22 of the pressing chamber is provided with a waterproof cylinder 221, and the waterproof boss 521 is sleeved outside the waterproof cylinder. Both the waterproof cylinder 221 and the waterproof boss 521 are provided with a through hole 5211 for the screw shaft to pass through. The upper end of the cylinder is provided with a waterproof sealing ring. Afte...

Embodiment 3

[0060] The difference between this embodiment and the first embodiment lies in that the structure of the fruit puree device is different.

[0061] Such as Figure 4 As shown, in this embodiment, the inner wall of the pressing chamber is partially recessed to form an auxiliary discharge channel 24, and the annular side wall 51 of the puree device is partially extended upward to form a baffle 54 that cooperates with the auxiliary discharge channel. No mesh is set, the depth of the auxiliary discharge channel 24 gradually increases from top to bottom, the inner ring surface formed by the baffle plate 54 and the side wall 21 of the pressing chamber cooperates with the screw rod 3 to process materials, and the auxiliary discharge channel 24 makes the puree Or the ice cream has more buffer space, so as to prevent the ground puree from accumulating too much in the pressing chamber 2 and not being discharged in time. The auxiliary discharge channel communicates with the discharge cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com